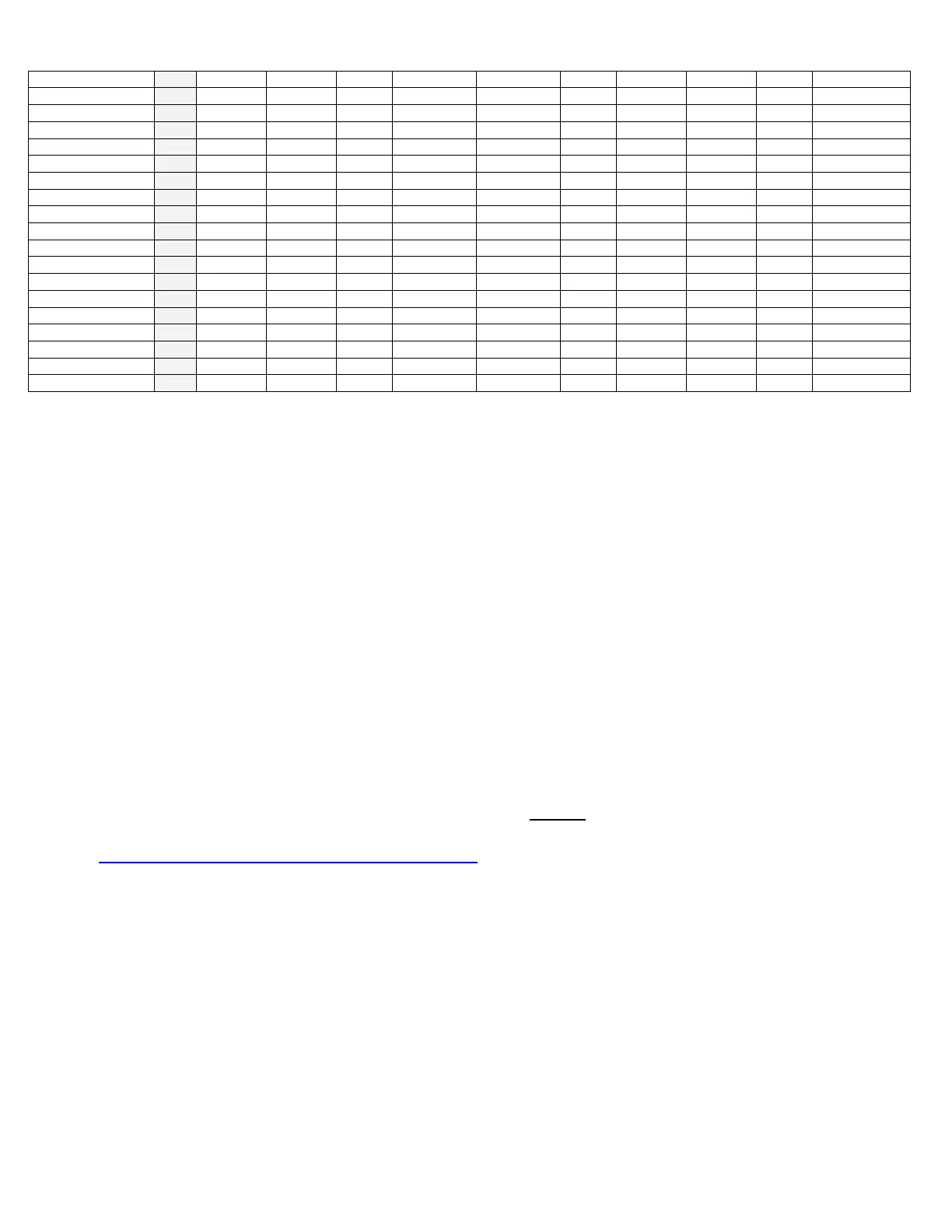

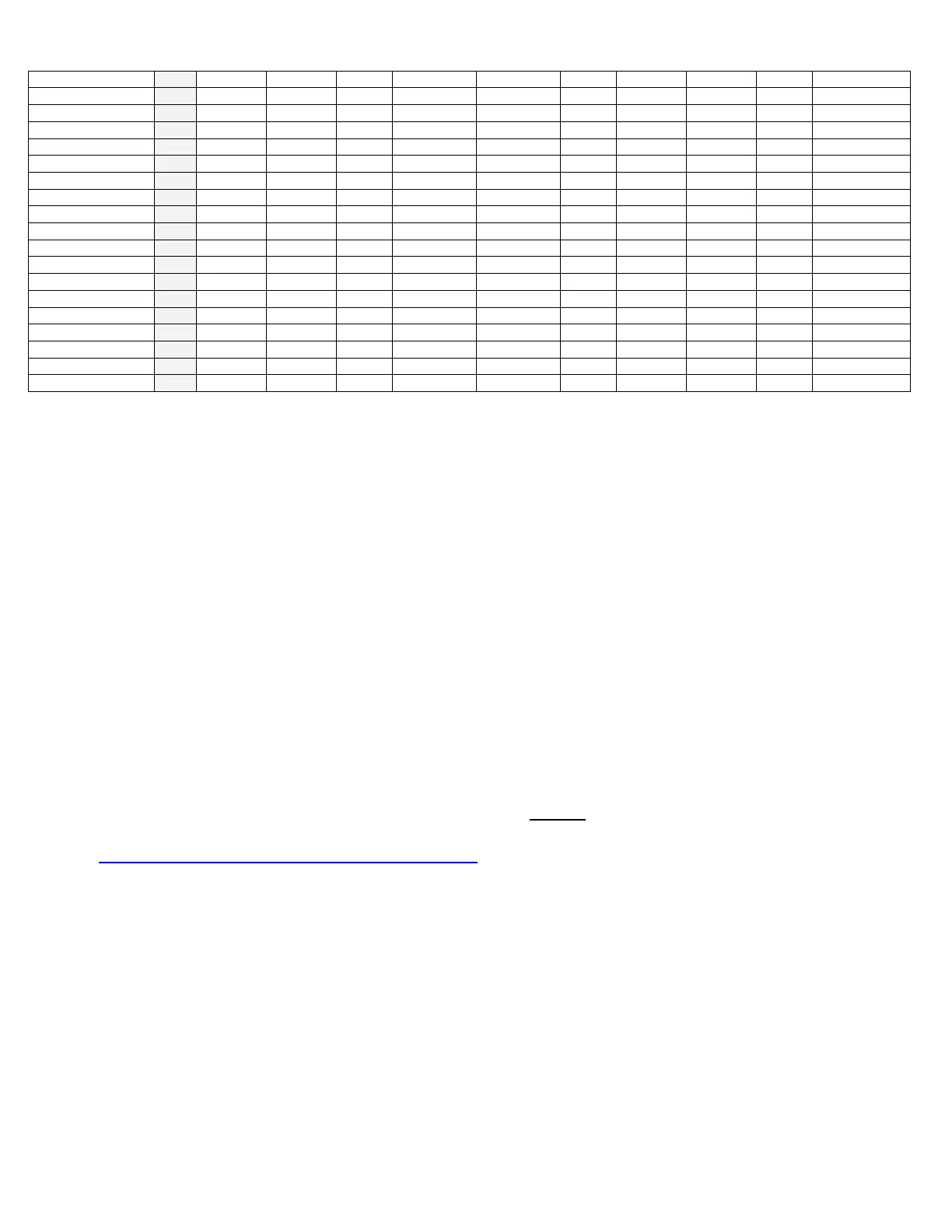

ALLOY SEPARATIONS CHART

* TE Readings for reference only. Subject to customer’s independent evaluation and testing for

suitability. The TE readings in the above chart are reflective of actual results of metal samples,

but may not necessarily reflect results observed in the field. The readings included in this chart

are intended to be used as a reference to aid the instrument user in determining the efficacy of

the Thermo-Electric Method.

LIMITATIONS

Thermoelectric response is inherently a comparison method of identification because individual

elements cannot be quantitatively determined. Some alloys differ only slightly in one or two

elements and the change in voltage on the tester is too slight to produce a different reading.

Some alloys have elements in them which may offset one another to produce nearly identical

readings overall. Alloys of identical chemical makeup but with different physical hardness

structure usually have different readings.

Additionally, the thermoelectric response procedure cannot differentiate between Stainless

Steel 316 and 304. The Spotter 316 can do the job. For more information, check out

https://www.koslow.com/select_metal_test_kit.

Loading...

Loading...