HELPFUL HINTS

• Do not operate TEAS close to a fan or point of high air motion. Wind will dissipate the

heat from the test area, causing poor readings.

• Hold the Hot Probe in contact with the test metal for only about 2 seconds & read the

display. Lift probe off test metal for two seconds allowing probe temperature to stabilize.

Repeat this cycle. Rushed testing without pauses may result in reading drift.

• Be sure the test metal and hot tip of the probe remains clean.

• If tip becomes marred or misshaped, unscrew and replace.

• Confirm that the tip is completely screwed tightly into the probe shaft. Loose tips could

give weak readings. Use of a hand-held crimping tool (Part No. TE-3000 F) is

recommended for proper torque without scratching tip.

•

PREVENTATIVE MAINTENANCE & CALIBRATION

• The Thermoelectric Alloy Sorter Model TE-3000-HD is supplied with an Initial Certificate of

Calibration. Koslow Scientific Co. recommends yearly calibration services known as a

“field” Certificate of Calibration (Service No. TE-3000-C). This certificate contains before

and after calibration data and the expected manufactures criteria. Aspects of the document

are N. I. S. T. traceable.

• Maintain kit by storing in a cool, dark place.

• Annual calibration cycles can be logged on the last page of this instruction manual.

Maintenance items are the responsibility of the customer/user. Failure to observe these

recommendations may adversely affect the operation of the equipment.

SIGNAL JACKS

The TE-3000-HD is supplied with one black and one red female banana jack on the top of the

instrument. These terminals can be used to interface with automation equipment, PLC’s

(Programmable Logic Controls) and data logging equipment. The output signal is an analog DC

millivolt signal.

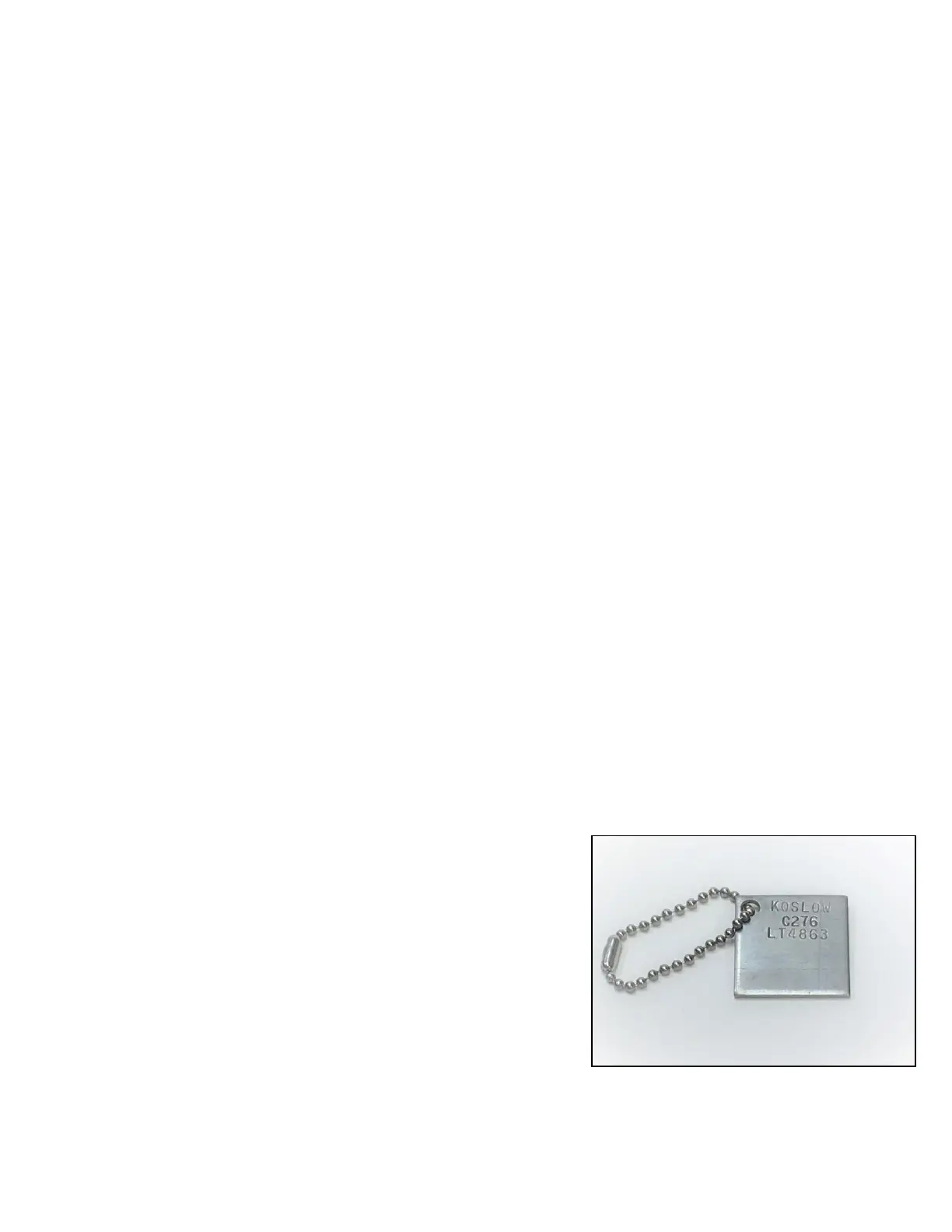

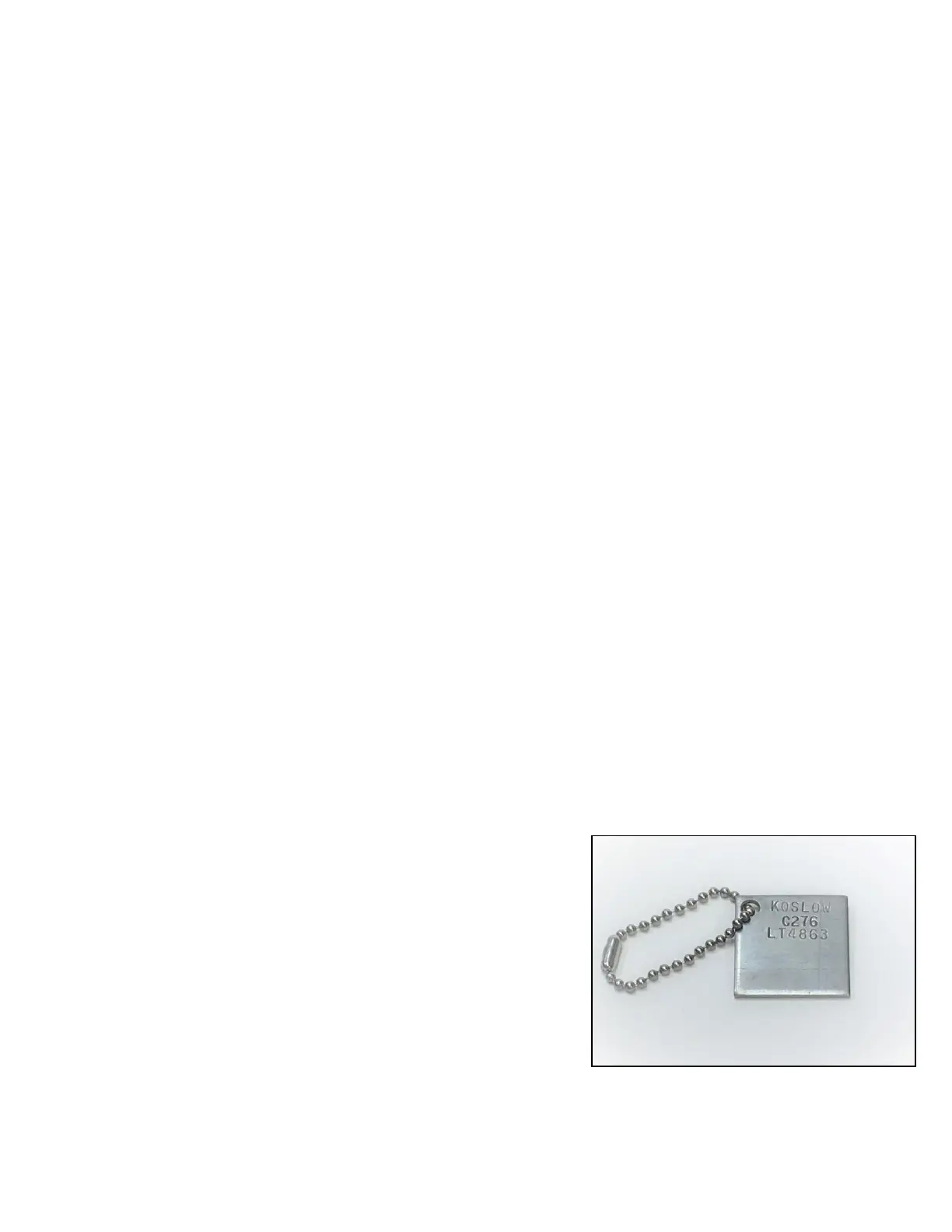

DAILY QUALIFICATION STANDARD

The kit includes a Daily Qualification Standard, (DQS) a

1-inch square plate of a nickel alloy. The DQS is

attached to the side of the machine with a small chain.

The DQS is principally used to confirm repeatability. It

acts as a calibration registration point for all the other

readings.

Loading...

Loading...