GB-3

▷ The switching differential of the pressure switch

may not exceed ±10% of the set value.

Example:

inlet pressure p

u

= 100mbar,

set switching pressure p

u

/2 = 50mbar,

max. switching differential 50mbarx 10%=

5mbar.

The switch-on and switch-off pressure must be

between 45mbar and 55mbar.

Wiring

CAUTION

Electric shocks can be fatal!

– Before working on possible live components,

ensure the unit is disconnected from the power

supply.

Please observe the following to ensure that the TC

is not damaged during installation:

– Incorrect wiring may result in unsafe states and

the destruction of the tightness control, the au-

tomatic burner control unit or the valves.

– Do not reverse L1(+) and N(–).

Disconnect the system from the electrical power

supply.

Shut off the gas supply.

Open the housing cover of the TC.

▷ Electrical connection: 2.5mm

2

terminals.

▷

The data on the type label must comply with the

mains voltage.

4 Prepare knock-out holes at the appropriate cable

glands.

▷ Use the NO contacts 3COM and 2NO on the

pressure switch (p

e

/2=p

u

/2).

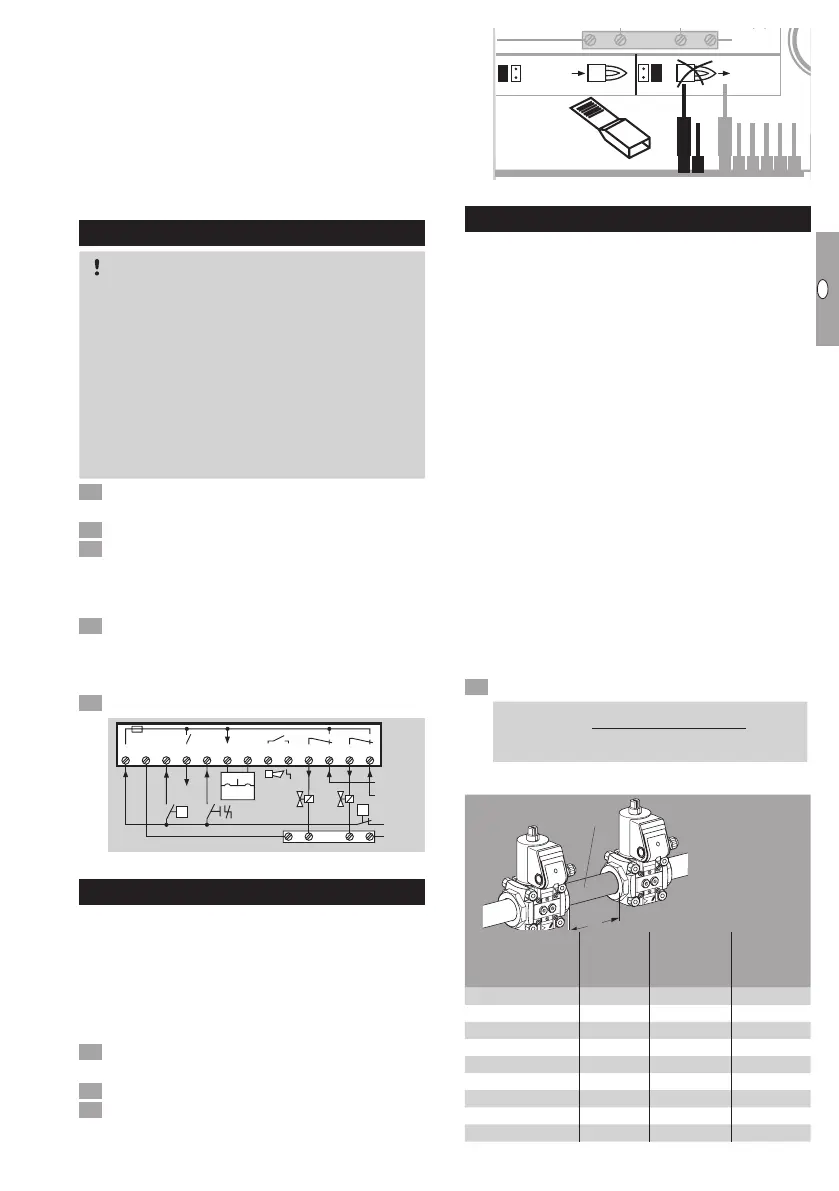

5 Electrically wire TC410.

1 2 3 4 5 6 7 8910 11 12 13

max. 1 A,

264 V

L1(+)

V1

L1(+)

V2

OK

ϑ

V2

V1

L1(+)

N(-)

ϑ

max

p

e

/2

N

Setting the test instant

▷

The test instant (MODE) can be set inside the

housing using a jumper.

▷ Mode 1: test before burner start-up with incom-

ing ϑsignal (factory setting).

▷

Mode 2: test after burner run with outgoing ϑsig-

nal and also after switching on the mains voltage.

▷ Without jumper = test before burner start-up.

Disconnect the unit from the electrical power

supply.

Unscrew the housing cover.

Set the test instant with a jumper, MODE 1 or2.

N

12 12

"TEST:"

TEST"

:"

Setting the test periodt

P

▷

The test period t

P

is set at the works to 10s

(100s) on TC410-1 (TC410-10) and can be

changed with a jumper in increments of 10s

(100s) to a max. of 60s (600s).

▷ Without jumper = 60s (600s).

▷

The longer the test periodt

P

, the smaller the leak-

age rate at which a safety shut-down is triggered.

▷ If no leakage rate is specified, we recommend

the max. test period is set.

▷

If a leakage rate is specified, find the test pe

-

riodt

P

from the following:

Q

max.

= max. flow rate [m

3

/h]

Q

L

= Q

max.

[m

3

/h] x 0.1% = leakage rate [l/h]

p

u

= inlet pressure [mbar]

V

P

= test volume [l], see page3 (Values for

valve and pipe volume)

▷

The tightness control TC requires a minimum

start rate in order to carry out tightness tests

on slow opening valves:

up to 5l (1.3gal) test volume V

P

= 5% of maxi-

mum flow rateQ

max.

,

up to 12l (3.12gal) test volume V

P

= 10% of

maximum flow rateQ

max.

.

Determine test period t

P

.

t

P

[s] = 4x

(

p

u

[mbar] x V

P

[l]

+ 1 s

)

Q

L

[l/h]

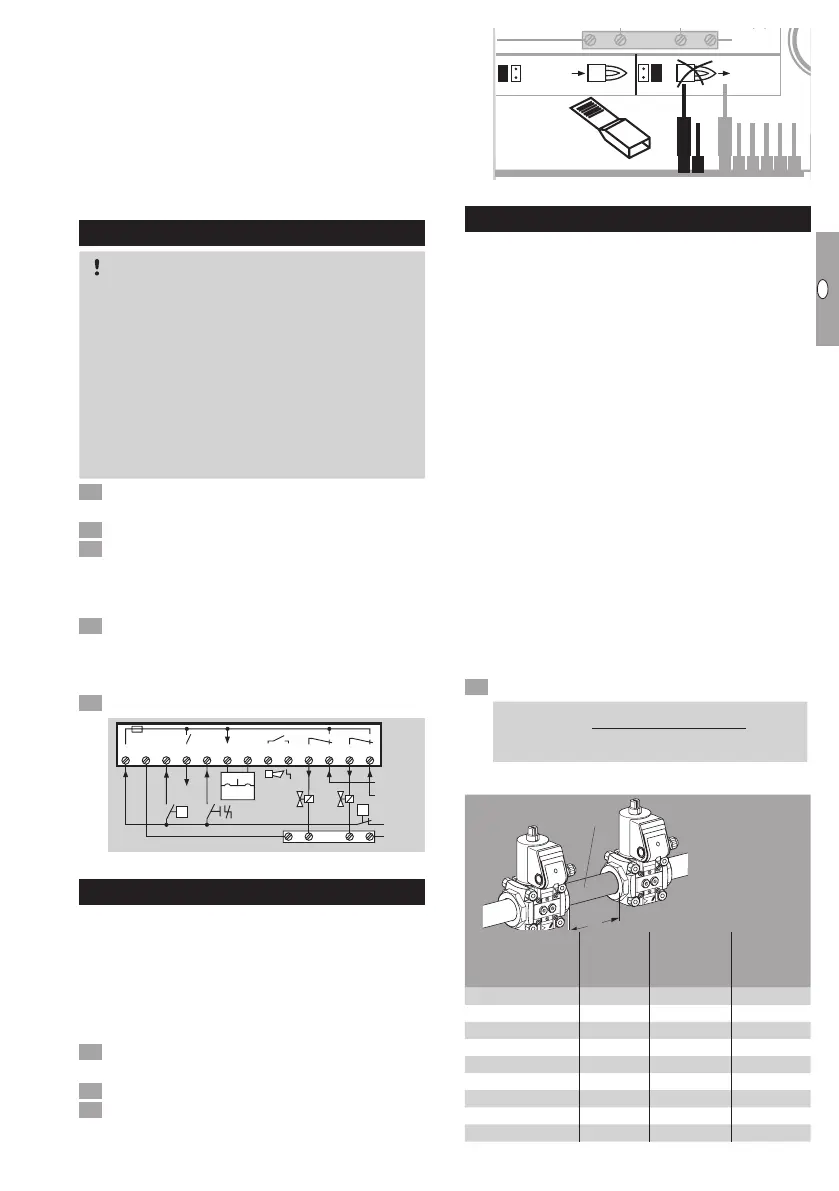

Values for valve and pipe volume

P

V1

V2

Valves

Valve

volume

V

V

[l]

Nominal

size

DN

Pipe

volume

V

R

[l/m]

VG 10 0.01 10 0.1

VG 15 0.07 15 0.2

VG 20 0.12 20 0.3

VG 25 0.2 25 0.5

VG 40/VK 40 0.7 40 1.3

VG 50/VK 50 1.2 50 2

VG 65/VK 65 2 65 3.3

VG 80/VK 80 4 80 5

VG 100/VK 100 8.3 100 7.9

Loading...

Loading...