Operations and Maintenance Manual 1-5

KWIK-WALL Company Operable Wall Systems

OPERATION: Retracting the Wall System

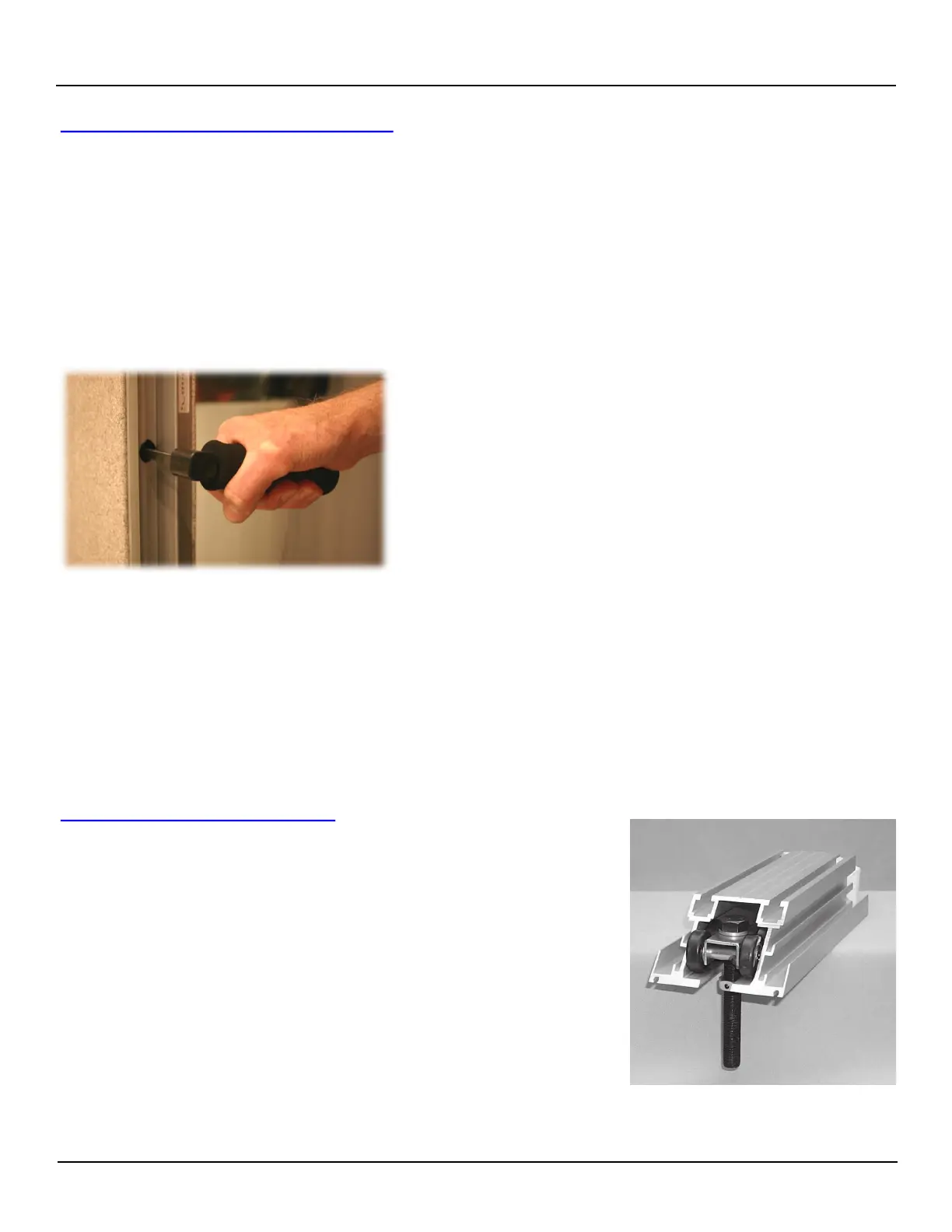

1. To retract the wall system, insert the removable wrench into an escutcheon plate located on the face

of the trail panel and rotate to release the Expander mechanism.

2. Gently pull the panels until they separate from the adjacent panel. Slowly push them back to the stack

area. Then fold the panels in the retracted position and push into the stack.

3. Disengage the Operable Bottom Seal from the next set of panels by inserting the removable wrench

into the opening located in the edge of the panel. Rotate the wrench to RETRACT the Bottom seal.

Continue rotating wrench until mechanism is fully retracted into the panel.

4. Gently pull the panels until they separate from the

adjacent panel. Grasp the edge of the Hinged Pair

panel group on both faces and walk toward the stack

end. When they reach the storage location, fold the two

panels together and slowly push them back into the

stack area.

5. Repeat the same routine until all the panels have been

removed from the set up location.

Remember: DO NOT ATTEMPT TO MOVE PANELS WITH THE OPERABLE BOTTOM SEALS

TOUCHING THE FLOOR.

HINGED PAIR ALUMINUM TRACK

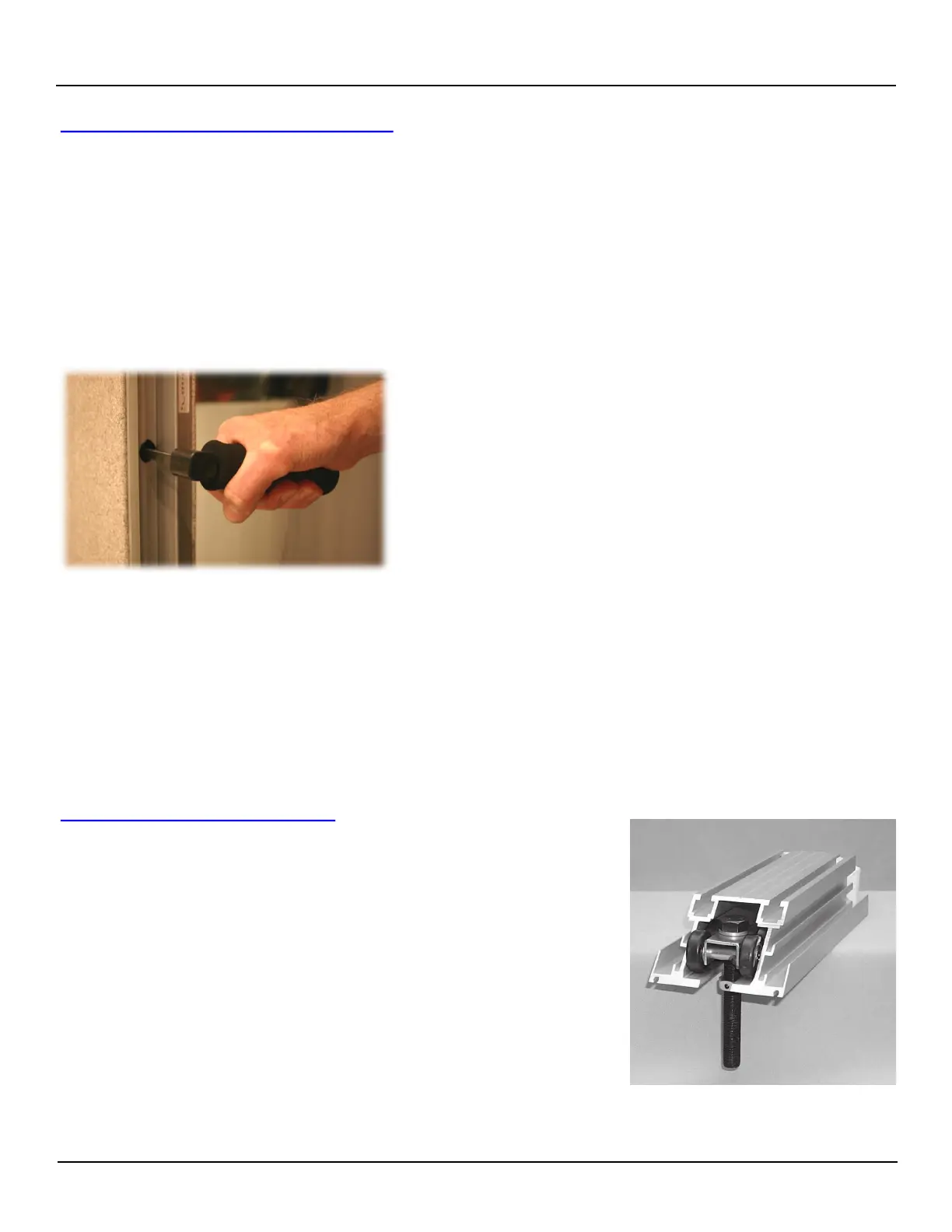

The Track System is extruded from aluminum and should require only

annual cleaning of the inside flanges. Every six months check the overall

track condition for smoothness and proper alignment. Then lubricate the

inside bottom flange with “Sil-Glyde”.

KWIK-WALL offers 425 Hinged Pair Aluminum track as our standard

feature capable of supporting up to 425 lbs. of total live load weight per

panel. For all panels that weigh over 425 lbs., 850 Hinged Pair Aluminum

track will be used and is capable of supporting up to 850 lbs. of total live

load weight per panel. As an option, KWIK-WALL also offers 850 Steel

Track constructed of durable powder-coated, off-white finish and is

capable of supporting up to 850 lbs. of total live load weight per panel

Loading...

Loading...