establish the likely performance of the system at

peak periods.

4.4 It is essential, for reasons of safety and

performance, that installation of the system is

undertaken only by a

competent person

working

in accordance with this Detail Sheet.

4.5 The data shown in Tables 3 and 4

represent the analysis of tests carried out by the

BBA.

5 Hot water storage and supply

Hot water storage

5.1 The capacities of the system range are

comparable with conventional systems (see

Table 1). When heated to 60°C the system can

supply 70% of the storage capacity at the mean

temperature given in Table 3.

Flow rates

5.2 The flow rates achieved at the hot water

draw-off point will depend on all the normal

factors including the layout of the pipework from

the tap to the cylinder, the cold water supply

pressure and the flow rate available at the supply

to the system.

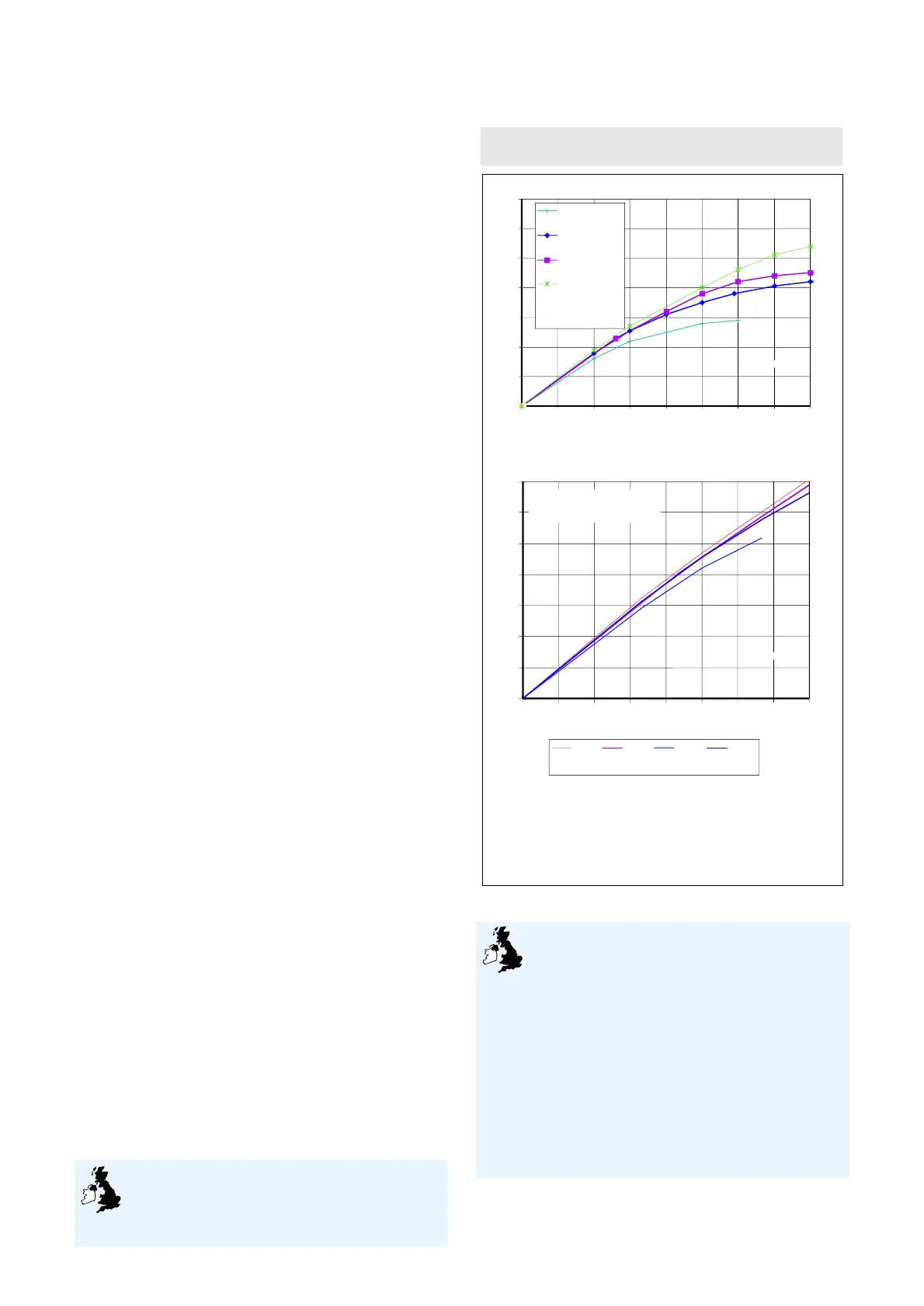

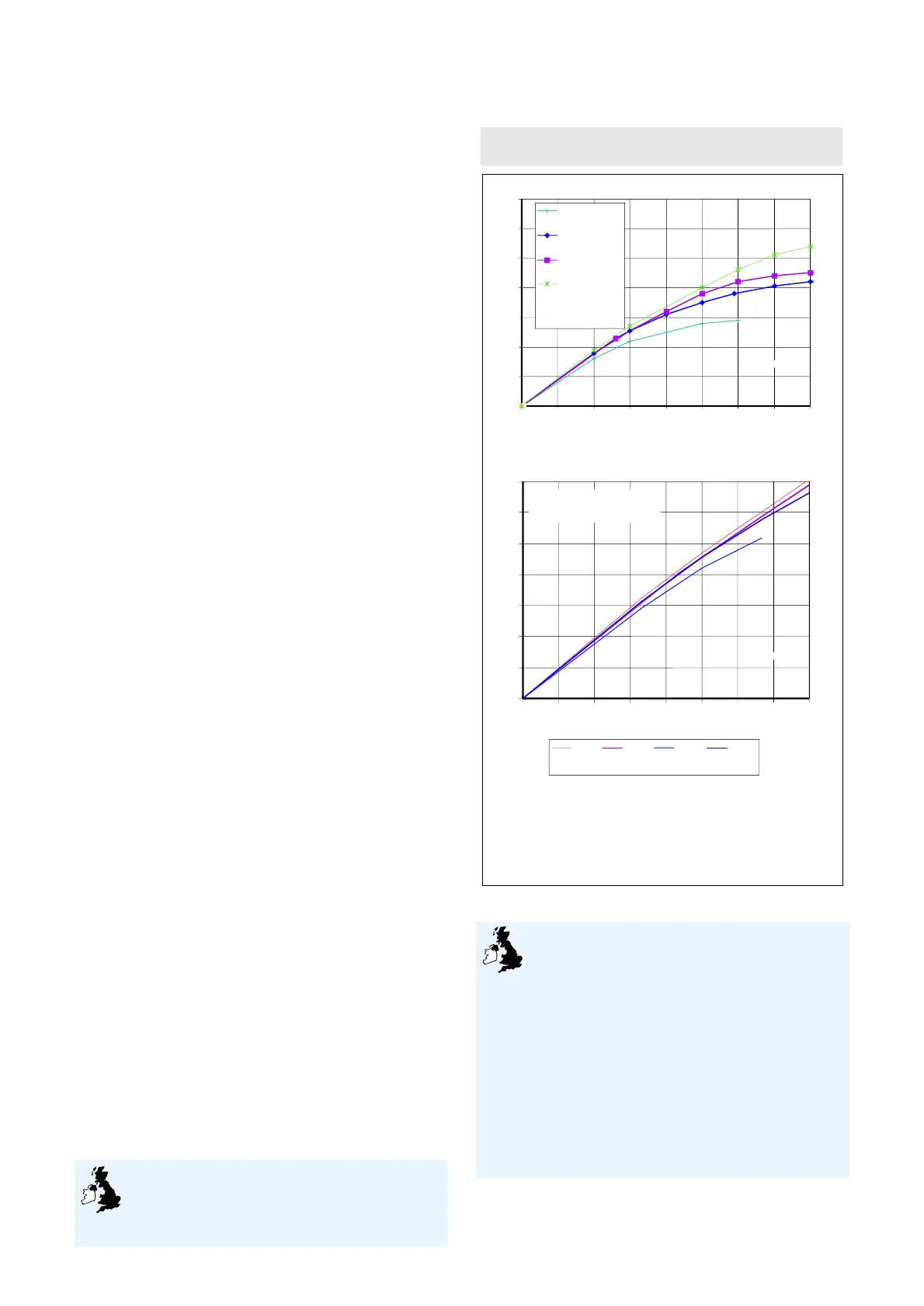

5.3 For design purposes the graphs in Figure 3

show the relationship between:

• flow available

• mains supply pressure, and

•

the maximum hot water flow rate out of the

system

(1)

.

(1) Flow characteristics shown in the graphs reflect the worst

combination of cold water control components that may

be installed (see Detail Sheet 2).

5.4 The hot/cold mixed flows are for draw-off

temperatures of 40°C (assume 60% at 60°C and

40% at 10°C).

Heat-up, re-heating and hot water draw-off

temperature

5.5 The heat-up and re-heat times are comparable

with conventional systems of a similar size

supplying hot water.

5.6 The immersion heater will heat the stored

water from 15°C to 60°C in the time listed in

column A of Table 3.

5.7 The amount of water that can be drawn off

within 10°C of the set temperature is listed in

column B of Table 3, the mean temperature of

70% of the water drawn off immediately after

reaching 60°C in column C, and the time taken

to re-heat the stored water to 60°C in column D.

Temperature control

5.8 The thermostats wired to the

immersion heater and motorised valve are

satisfactory for controlling the temperature

of the stored water.

Pressure control

5.9 The pressure control valve is satisfactory for

controlling the pressure of the water supplied from

the water mains or other suitable potable supply.

Figure 3 Flow rates

Insulation

5.10 The system is provided with

adequate insulation to satisfactorily limit

the energy loss from the stored water and

meets the requirements described in the national

Building Regulations:

England and Wales

Approved Document L1

Scotland

Regulation 22, Standard J3.4

Northern Ireland

Technical Booklet F, Paragraph 3.3.

5.11 The heat loss of each system while

maintaining the temperature of the stored water at

65°C is shown in Table 4.

0

10

20

30

40

50

60

70

0

10

20 30 40 50 60

70

80

2 bar

3 bar

4 bar

8 bar

Static supply pressures

of incoming water

supply

flow available (lmin ) at entry to system

–1

flow out (lmin ) of the system

–1

hot only

¾" valves

0

10

20

30

40

50

60

70

0 1020304050

60 70 80

flow available at entry to the system(lmin )

–1

8 bar 4 bar 3 bar 2 bar

Static supply pressures of incoming water supply

flow out (lmin ) of the system

–1

• Flow rates shown apply to situations where the supply is capable of supplying an

adequate dynamic pressure.

• The graph represents the results of tests carried out by the BBA.

• Where static water supplies are less than 1 bar, consult Kwikot Limited or the BBA.

• Flow rates shown for mixed hot/cold water assume that the cold supply is not

taken from the balanced connection of the pressure reducing valve

Notes

hot/cold mixed

mixed water at 40ºC, mixed from

60% hot water at 60ºC and

40% cold water at 10ºC

¾" valves

Loading...

Loading...