815 LX / UTILIZATION

CHAPTER 4 MAINTENANCE 41

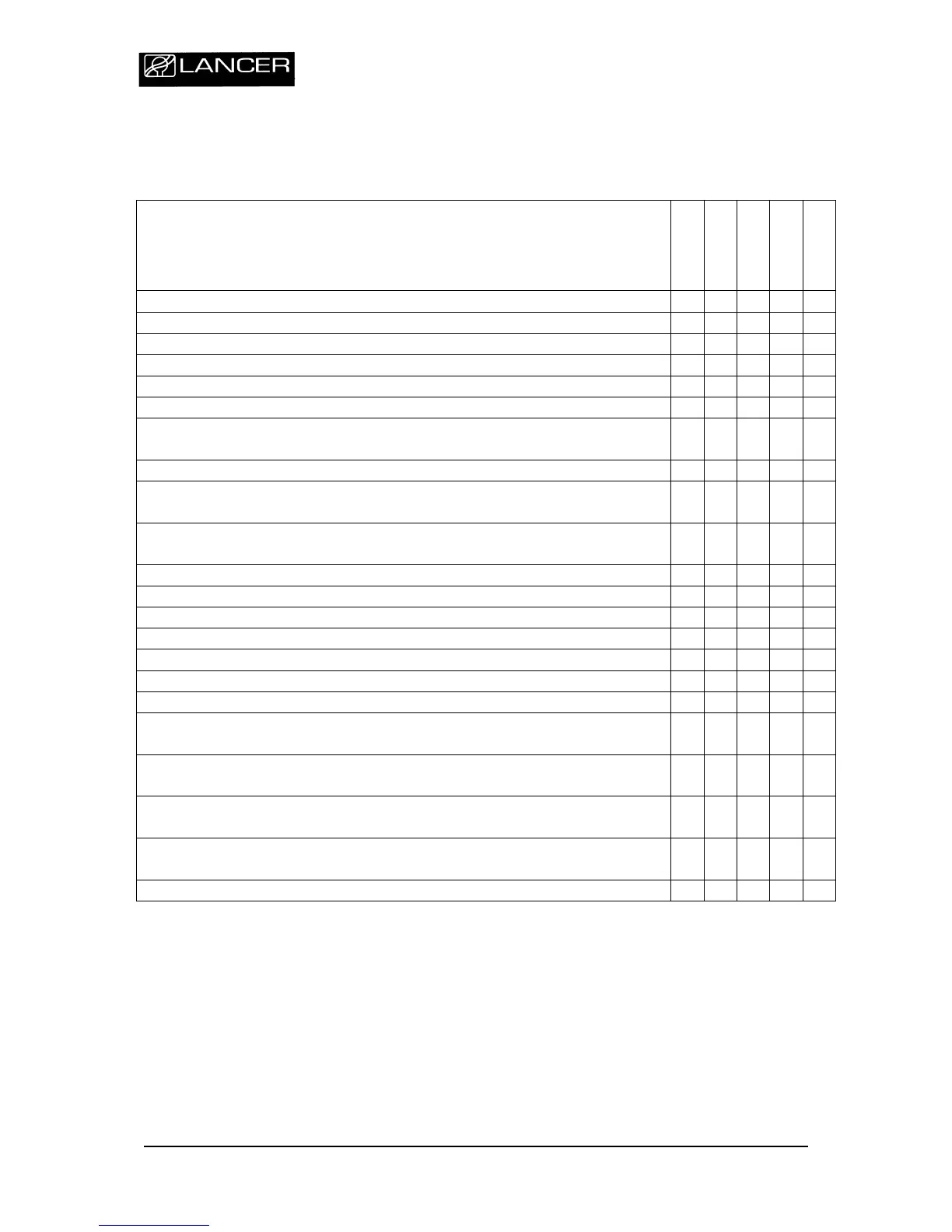

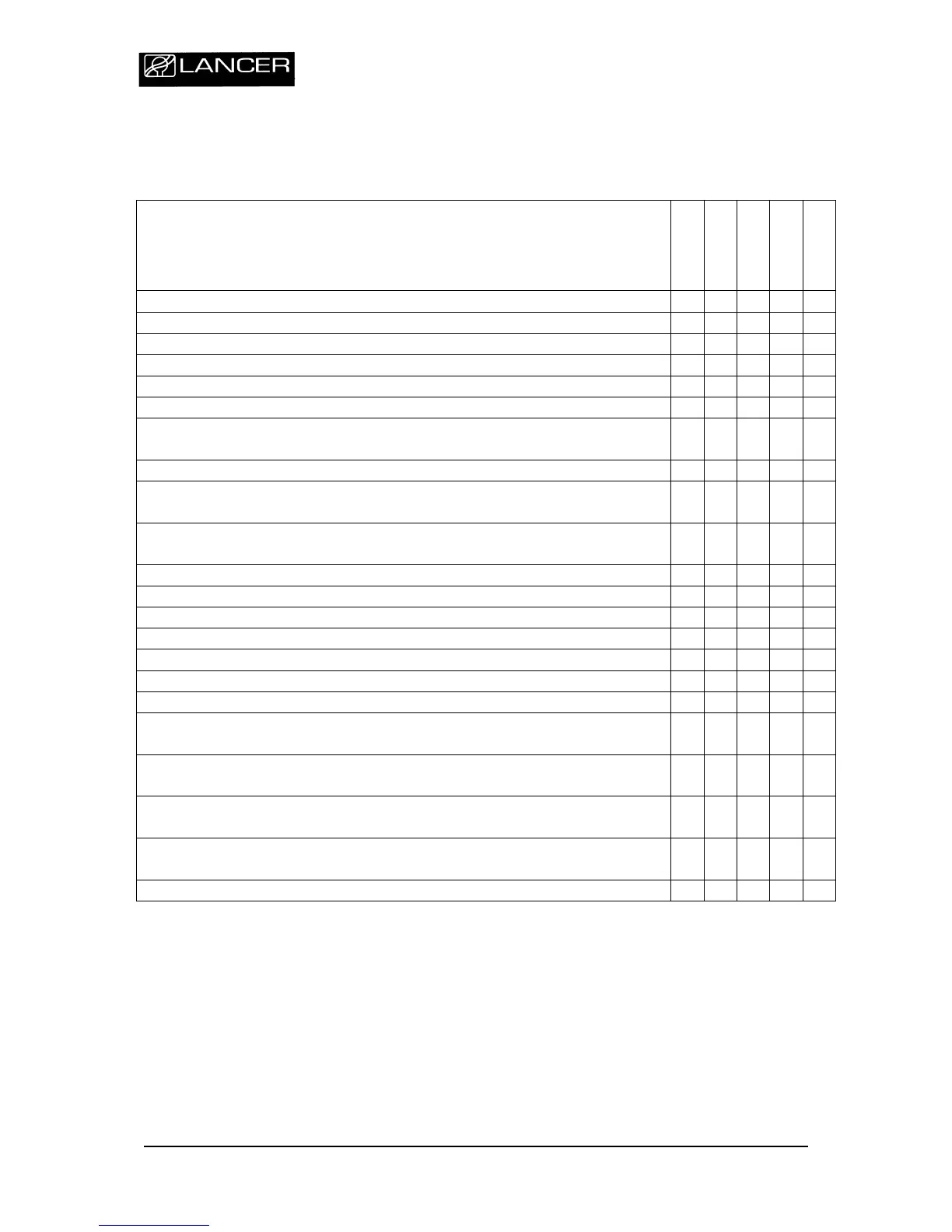

5. PREVENTATIVE MAINTENANCE SCHEDULE

FUNCTION

Daily

Biannual

1 Year

2 Year

5 Year

C

LEAN FILTER SYSTEM IN CHAMBER

.

X X X X X

C

HECK CHEMICAL CONTAINERS FOR ANY LEAKAGE

.

X X X X X

E

NSURE CHEMICAL HOSES ARE NOT PINCHED

.

X X X X X

C

LEAN EXTERIOR PANELS

.

X X X X X

I

NSPECT WATER SUPPLY HOSES FOR CRACKS

,

BULGES

,

AND LEAKS

.

X X X X

E

NSURE THE WATER HOSE SEALS AND FILTERS ARE CLEAN AND HAVE NO

CRACKS

.

X X X X

C

HECK CHEMICAL SUPPLY HOSES FOR CRACKS

,

BULGES AND LEAKS

.

X X X X

I

NSPECT INTERNAL TUBING ON CHEMICAL PUMPS FOR WEAR

.

(I

F APPLICABLE

)

X X X X

C

HECK CHEMICAL LEVEL SENSORS FOR CORRECT OPERATION

.

(I

F APPLICABLE

)

X X X X

E

NSURE ALL PANELS ARE PROPERLY SECURED

.

X X X X

C

HECK ALL INTERNAL HOSES FOR CRACKS

,

BULGES AND LEAKS

.

X X X X

E

NSURE ALL HOSE CLAMPS ARE PROPERLY TIGHTENED

.

X X X X

C

HECK ALL COLUMN SEALS FOR LEAKS AND CRACKS

.

X X X X

C

HECK SPRAY ARM SUPPORT SEALS FOR LEAKS AND CRACKS

.

X X X X

C

HECK SPRAY ARMS AND BUSHINGS FOR WEAR

.

X X X X

C

HECK DOOR SEAL AND GASKET FOR LEAKAGE

.

X X X X

I

NSPECT THE DOOR SPRINGS

,

DOOR WHEELS AND THEIR SLING

,

HOOKS

,

DOOR SWITCH FOR PROPER OPERATION

.

X X X X

C

HECK RECYCLING AND EMPTYING PUMP SEALS FOR LEAKAGE AND QUIET

OPERATION

.

X X X

C

HECK FOR LOSE ELECTRICAL CONNECTIONS AT COMPONENTS AND

ELECTRONIC CARDS

.

X X X

V

ERIFY THE CORRECT OPERATION OF ALL RELAYS AND THEIR ASSOCIATED

COMPONENTS

.

X X X

C

HANGE THE HEATING RELAY

.

X

(1) Daily maintenance must be handled by users staff.

(2) Others maintenances (bi-annual, 1 year, 2 years & 5 years) must be carry out by the Lancer’s

technical assistance service.

Loading...

Loading...