22

Maintenance

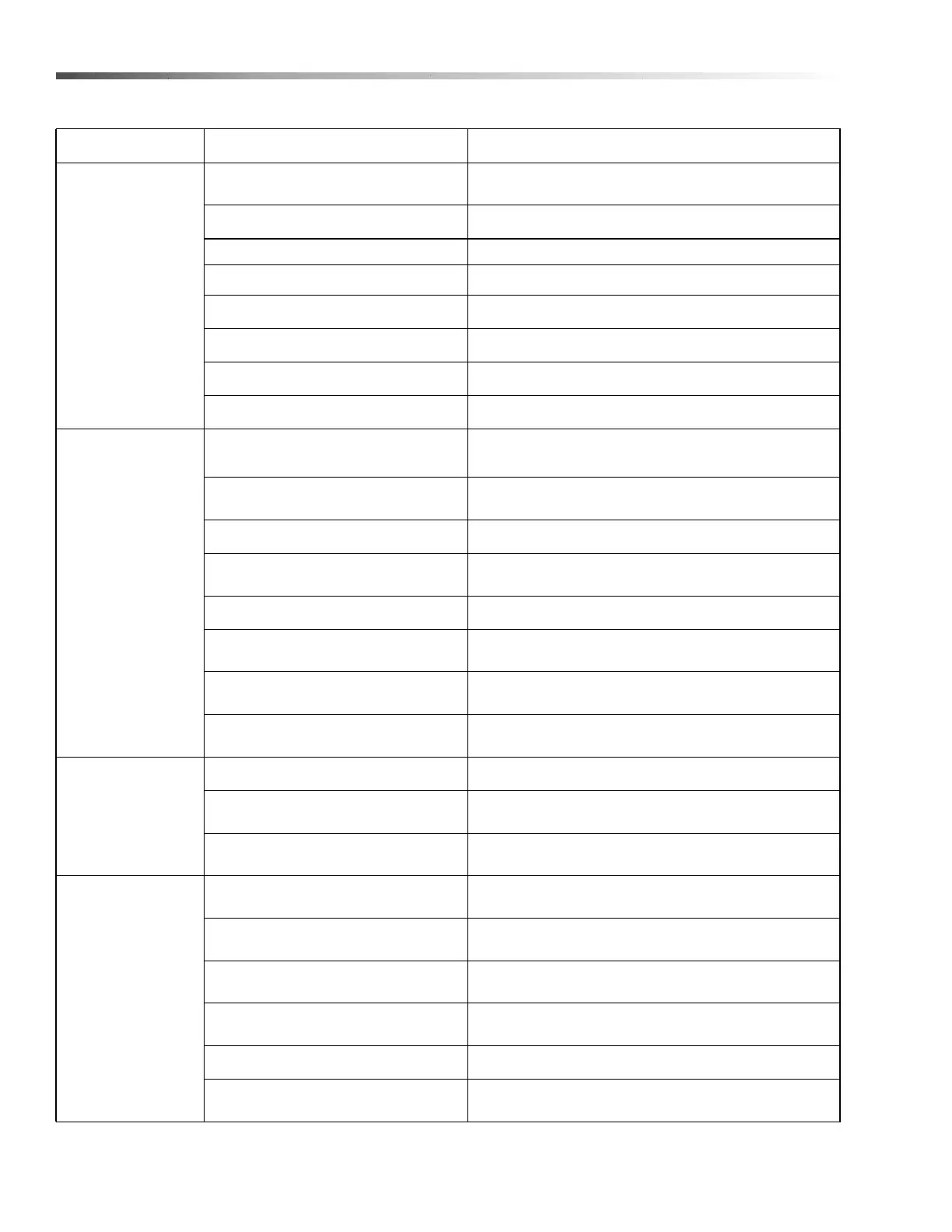

PROBLEM POSSIBLE CAUSE SOLUTION

WATER

TEMPERATURE

TOO HOT

Incoming water to machine warm or

hot

Lower incoming water temperature.

Fuel pump pressure too high Readjust fuel pressure.

Fuel pump defective Replace fuel pump.

Detergent line sucking air Tighten all clamps. Check detergent line for holes.

Defective high limit switch Replace.

Incorrect fuel nozzle size See exploded view parts list for proper size.

Insufficient water supplied Check GPM to machine.

Restricted water flow Check nozzle for obstruction and proper size.

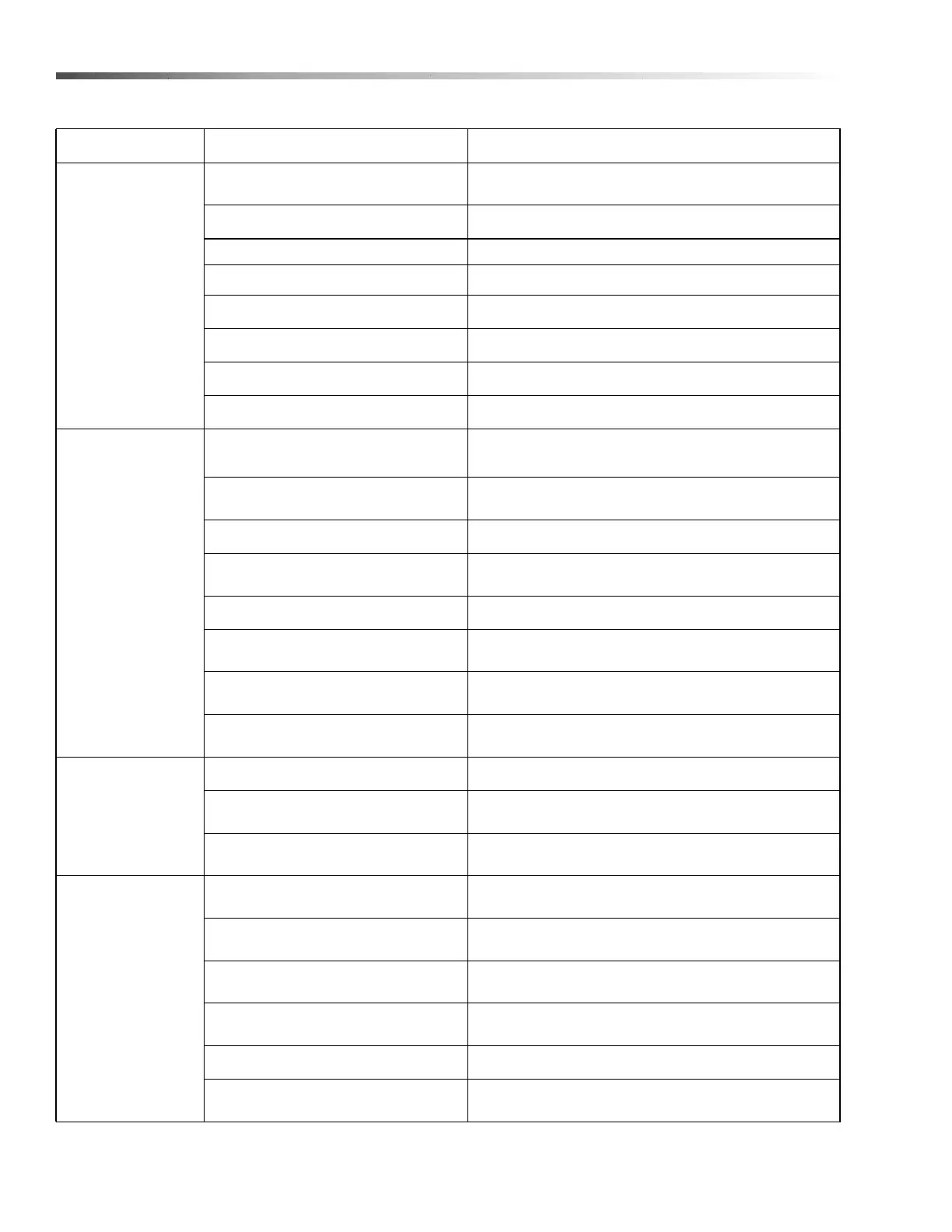

PUMP MOTOR

STOPS AFTER A

FEW MINUTES OF

OPERATION OR

STARTS SLOW

Insufficient voltage

Use heavier drop cord and check voltage at recep-

tacle. Check name plate for amperage draw.

Plugged nozzle

Remove and clean nozzle. Turn on water pump and

flush lines, replace nozzle.

Wrong spray nozzle See serial plate for minimum nozzle size.

Automatic overload switch tripped Allow motor to cool - switch will automatically reset.

Motor wet Allow to dry.

Short in electrical wiring

Wire contacts should be clean and tight. No breaks in

wires.

Coil liming up causing excessive

pressure

See section on Preventative Maintenance.

Water pump low or out of oil causing

the pump to bind up

Fill to correct level.

RELIEF VALVE

LEAKS OR

SPRAYS OUT

WATER

Spray nozzle plugged Remove nozzle and clean out obstruction.

Mis-adjusted or defective relief valve Adjust or replace as needed.

Scale or dirt plugging inside of coils See "Preventative Maintenance Cleaning of Coils."

DETERGENT NOT

DRAWING

Air leak Tighten all clamps. Check detergent lines for holes.

Detergent metering valve packing

not tight or packing worn

Tighten nut. Replace valve or packing.

Filter screen on detergent suction

hose plugged

Clean or replace.

Dried up detergent plugging metering

valve or injector

Clean and flush.

Restrictor in float tank missing Install restrictor.

High viscosity of detergent

Dilute detergent to specifications. Read detergent

label.

Landa PHW Operator’s Manual 8.917-417.0 - D

Loading...

Loading...