LM800 - LM800GR • 7

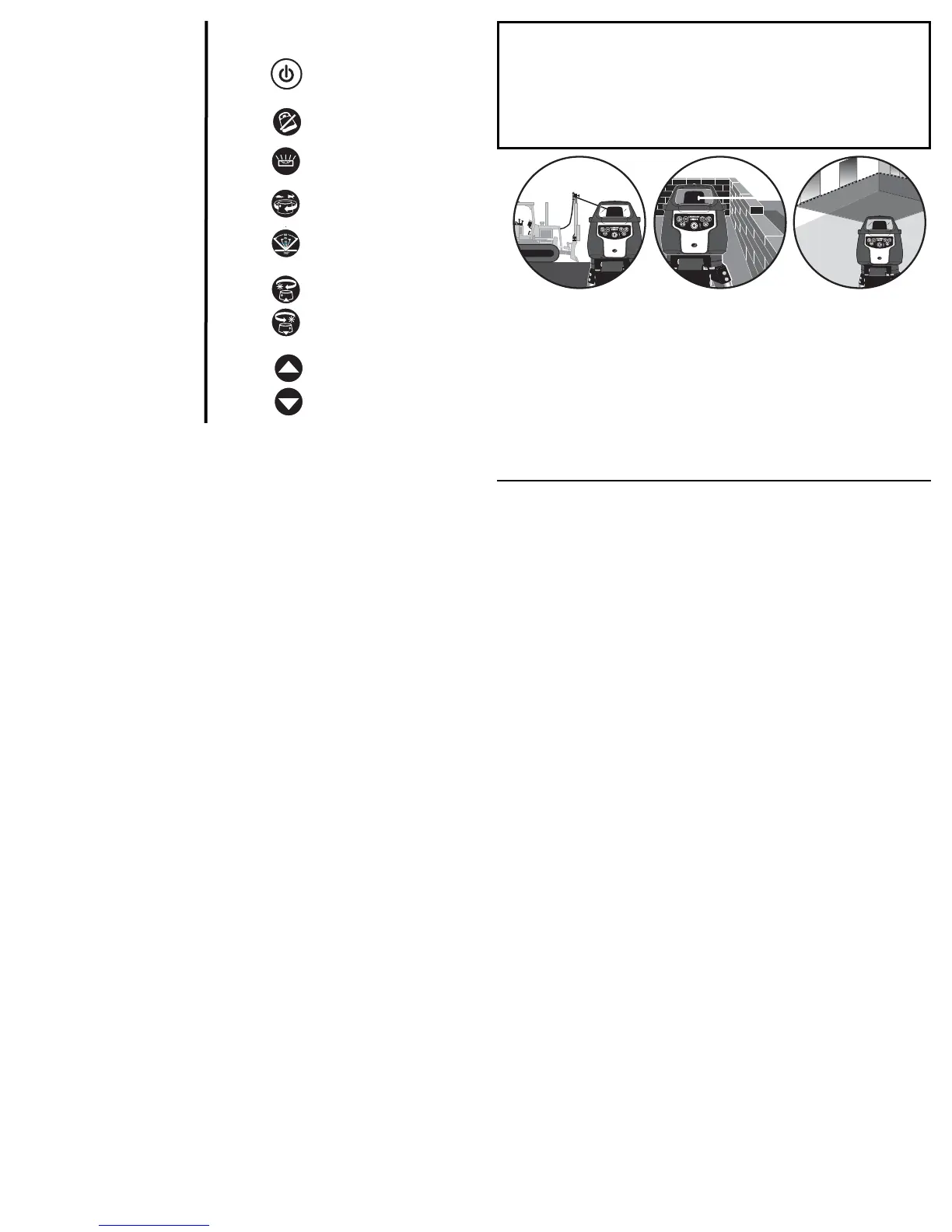

1 Glass Enclosed

2 Self-Leveling (with ±5º) Rotary Laser

Beam

3 Anti-Drift System LED Indicator

4 Manual Mode LED Indicator

5 Battery Level LED Indicator

6 Remote Sensor eye

7 Top Cage with Gun Sight with “X” &

“Y” Identifiers

8 Heavy-Duty Handle – Built-in Trivet

(LM800 only) for Laydown and

Vertical Jobs with 5/8- 11 Tripod

Threads

9 Down Plumb Beam (LM800 only)

6 • LM800 - LM800GR

APPLICATIONS

Use your LM800 Series Self-Leveling Laser for many projects including:

Outdoor General Construction Applications & Site Preparation, Grading & Excavating,

Batterboards and Foundations, Masonry Work, Setting Concrete Forms, Machinery

Installation, Marking Elevation, Septic Work, Paving Roads, Driveways, Checking Depth of

Trenches.

Drop Ceiling Installation, Floors, Cabinets & Shelves, Carpentry, Pools, Decks & Patios,

Flagpoles, Aligning 90° Joints & Edges, Landscaping, Tile Work, Septic Work, Plumbing,

Batterboards, Fencing, Walls & Partitions, Remodeling, Siding Installation, Doors & Windows.

Operating Instructions for General Construction Applications

Note: A level plane of laser light is created by the rotating beam of the laser. The laser light can be

used to reference elevations with the use of a laser detector.

1. Place the instrument on a flat, level surface such as a tripod. Setup the instrument in an

area where it can not be obstructed and is set at a convenient height.

2. Press the “A” button. Allow the instrument to self-level.

3. Setup a "Benchmark".

Note: Setup a Benchmark

During the work day, periodically check your initial set-up to ensure that the laser reference has

not moved.

Establish, at a suitable distance (furthest possible), a benchmark (reference) on a stable surface

(ie. tree, building). Periodically during the work day, check the benchmark to ensure that your

setup has not moved.

Power Button (Allow 60

seconds for instrument to self-

level)

For LM800 – Use also to

activate the Plumb Down Beam

ADS Button– Anti-Drift System

ON | OFF

Manual Mode/Automatic Level

Button

Variable Rotation Button– 4

Speed Selections (LM800 Only)

Sweep Button– 4 Preset

Scanning/ Angles and spot.

(LM800 Only)

CW and CCW Button

Clockwise andCounter- Clock-

wise Head Positioning (Press

and Hold Button Moves the

Rotation More Quickly

For LM800– Use also during

Grade Mode.

Manual Grade Adjustment

Buttons

(LM800 GR Only)

ICONS

Reference in

the text

Loading...

Loading...