ALL PRIMERS ARE DANGEROUS and it should be anticipated that the primers in the tray could explode through accident, misuse or spontaneously. Should

an explosion occur, our tests have demonstrated that safety glasses will normally prevent serious injury to the user. Primers are capable of exploding with

sucient force to seriously injure the user, or persons nearby. When loading primers—safety glasses and hearing protection must be used.

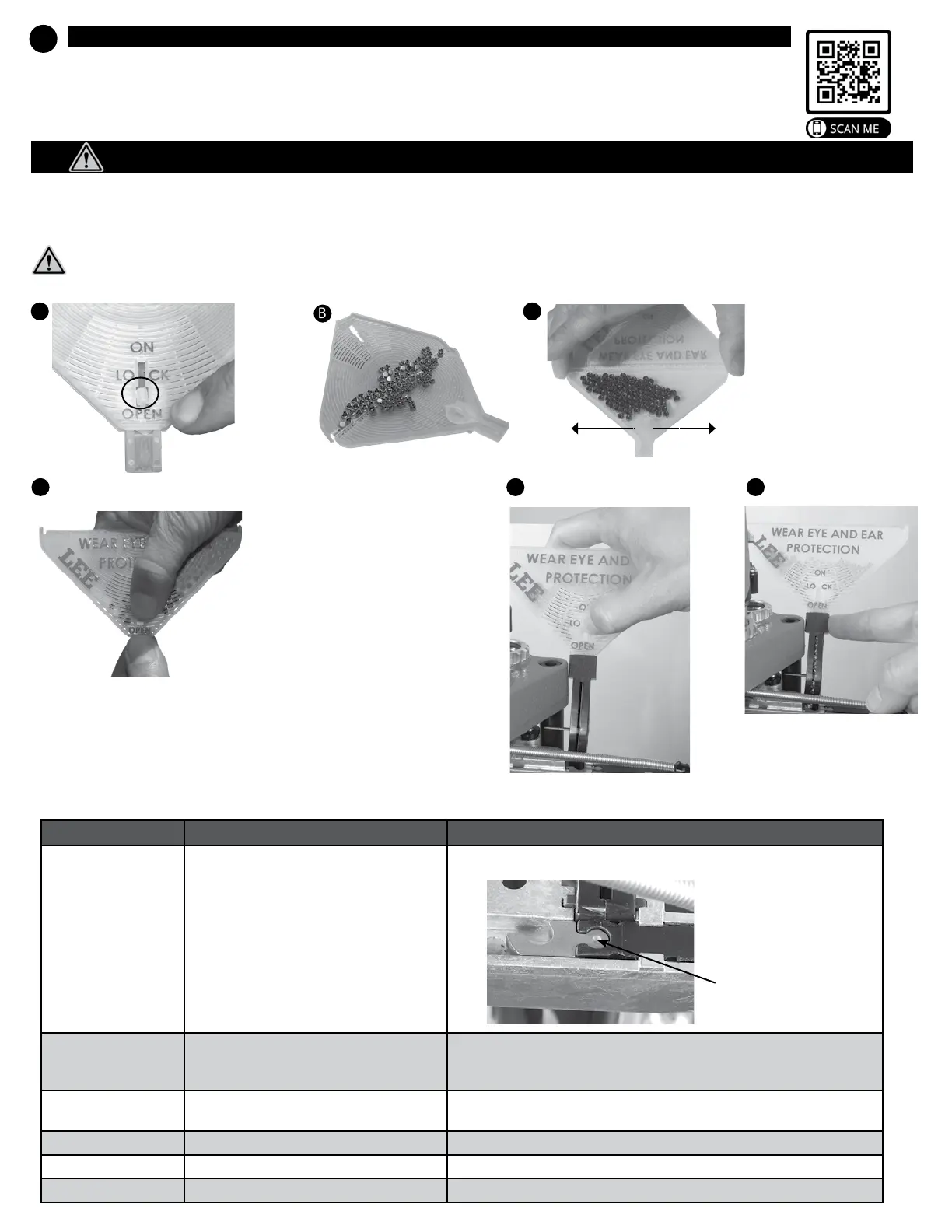

Slide the flow

control to

OPEN.

Lift tray so output spout

touches table, shake tray

side to side to upright all

the primers. Allow cover to

naturally fold up, notice how

the primers glide across hinge

upright themselves and work

their way towards the outlet.

Fold cover over, slide the flow control to

LOCK position, feel for the detent. Grasp

the top and bottom of the flow control valve

using your thumb and index finger above

and below tray.

NOTE: make sure it is in the LOCK detent

position, or else primers may spill.

Slide the tray into the trough. Slide

the flow control to the ON position.

A

B

C

D

E

WARNING: Handling live primers and spent primers may expose you to lead or other chemicals, which are known to the State of

California to cause reproductive harm and cancer. For more information, go towww.P65Warnings.ca.gov.

Randomly

deposit

primers.

Don’t let the primer level fall below the tray level. Once the last primer has exited the folding tray, replenish the primer

supply, or else you will be loading cases without primers.

DANGER: Primers can explode with sucient force to seriously injure the user or persons nearby.

IMPORTANT - Fill the primer feed tray. View help video for loading primers into tray:

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

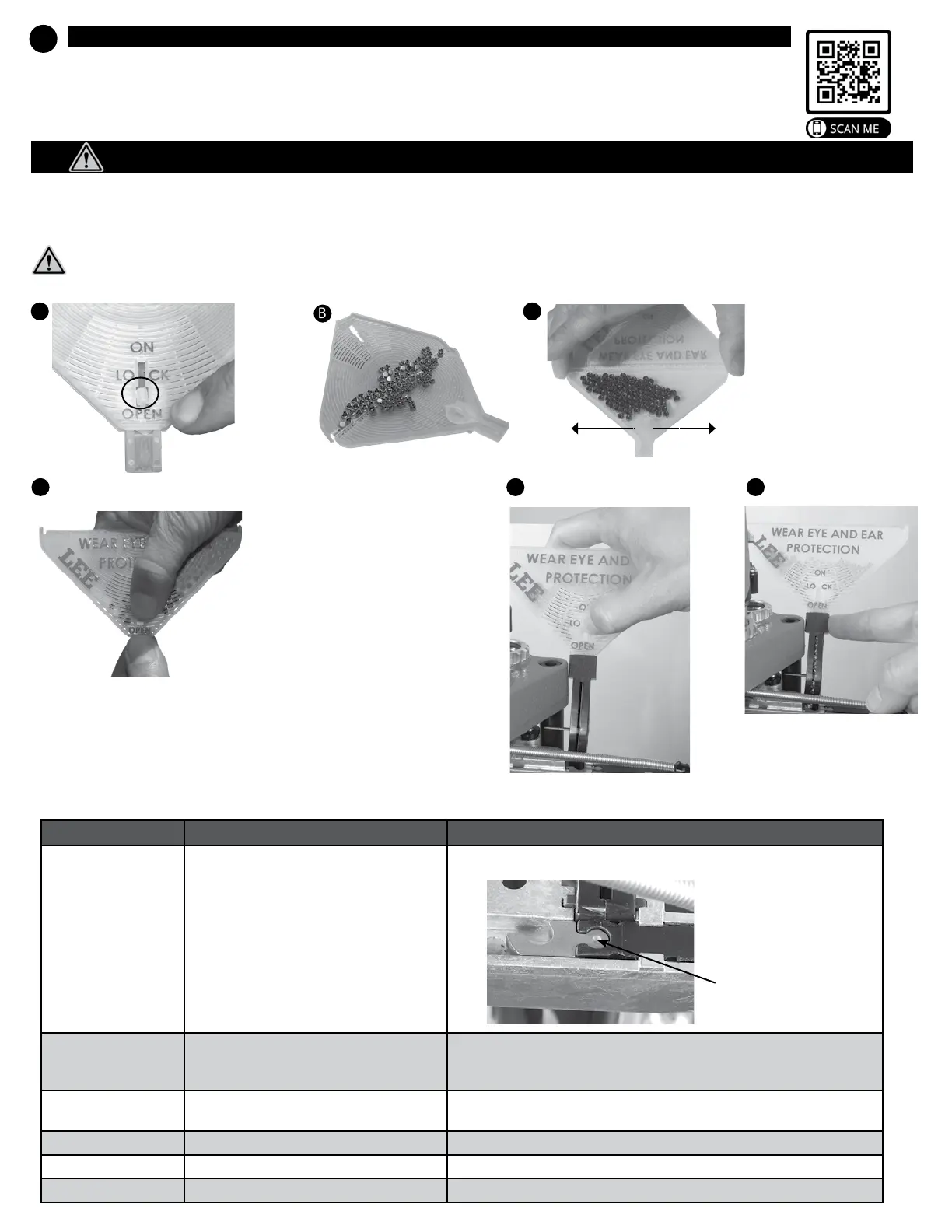

Primers will not feed

properly

• Wrong primer guide is installed or the primer

guid is installed upside down. The S and L must

be installed facing down. See Remedy >

• Install appropriate primer guide with letter facing down.

Primer doesn’t feed onto

priming punch

• Oil in trough

• Primer trough not full

• Remove all oil with solvent or blow out powder or dust with compressed air

• Always keep primer trough full, there must be a minimum of 5 primers in the

trough to feed properly

Primer doesn’t enter case

• Primer crimp not removed

• Wrong size primer

• Ream or swage primer pocket

• Caution, some 45ACP cases now have small primer pockets

Tipped primers • Case not fully in shell plate • Adjust case retainers

Cases don’t eject • Case ejector • Verify case ejector is installed

Shell plate does not index • Driver clutch missing or damaged • Rotate 90 degrees and re-install, or replace part # PR3691.

Large Primer Guide

# 91981

Small Primer Guide

shown installed.

Notice dimple on

attach boss.

# 91980

Tap the trough several times

to fill.

6

Install primer feeder

F

7

Loading...

Loading...