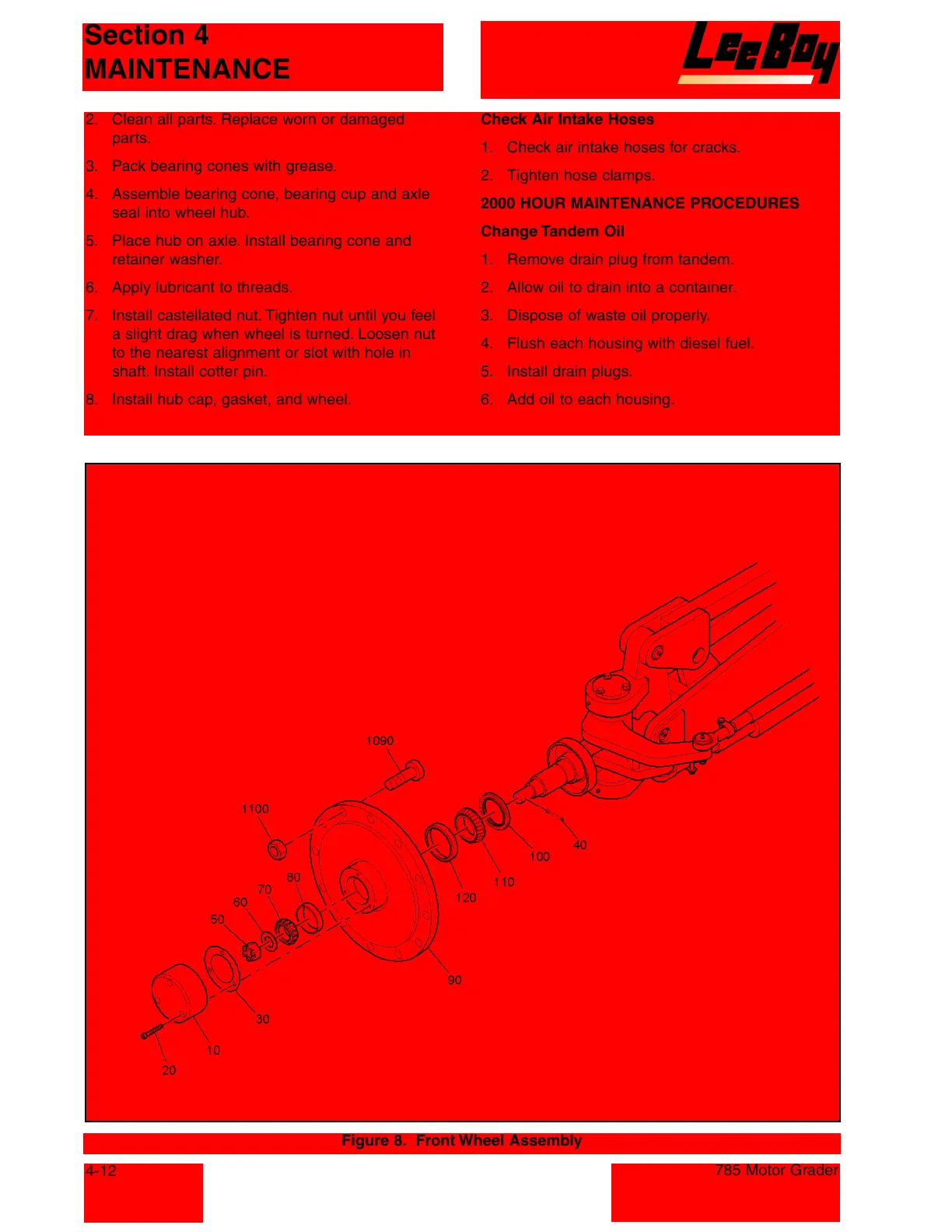

2. Clean all parts. Replace worn or damaged

parts.

3. Pack bearing cones with grease.

4. Assemble bearing cone, bearing cup and axle

seal into wheel hub.

5. Place hub on axle. Install bearing cone and

retainer washer.

6. Apply lubricant to threads.

7. Install castellated nut. Tighten nut until you feel

a slight drag when wheel is turned. Loosen nut

to the nearest alignment or slot with hole in

shaft. Install cotter pin.

8. Install hub cap, gasket, and wheel.

Check Air Intake Hoses

1. Check air intake hoses for cracks.

2. Tighten hose clamps.

2000 HOUR MAINTENANCE PROCEDURES

Change Tandem Oil

1. Remove drain plug from tandem.

2. Allow oil to drain into a container.

3. Dispose of waste oil properly.

4. Flush each housing with diesel fuel.

5. Install drain plugs.

6. Add oil to each housing.

Section 4

MAINTENANCE

4-12

785 Motor Grader

Figure 8. Front Wheel Assembly

Courtesy of Machine.Market

Loading...

Loading...