What to do if LeeBoy Farm Equipment light blinks twice, stops, then blinks 9 more times?

- DDebra AdamsAug 3, 2025

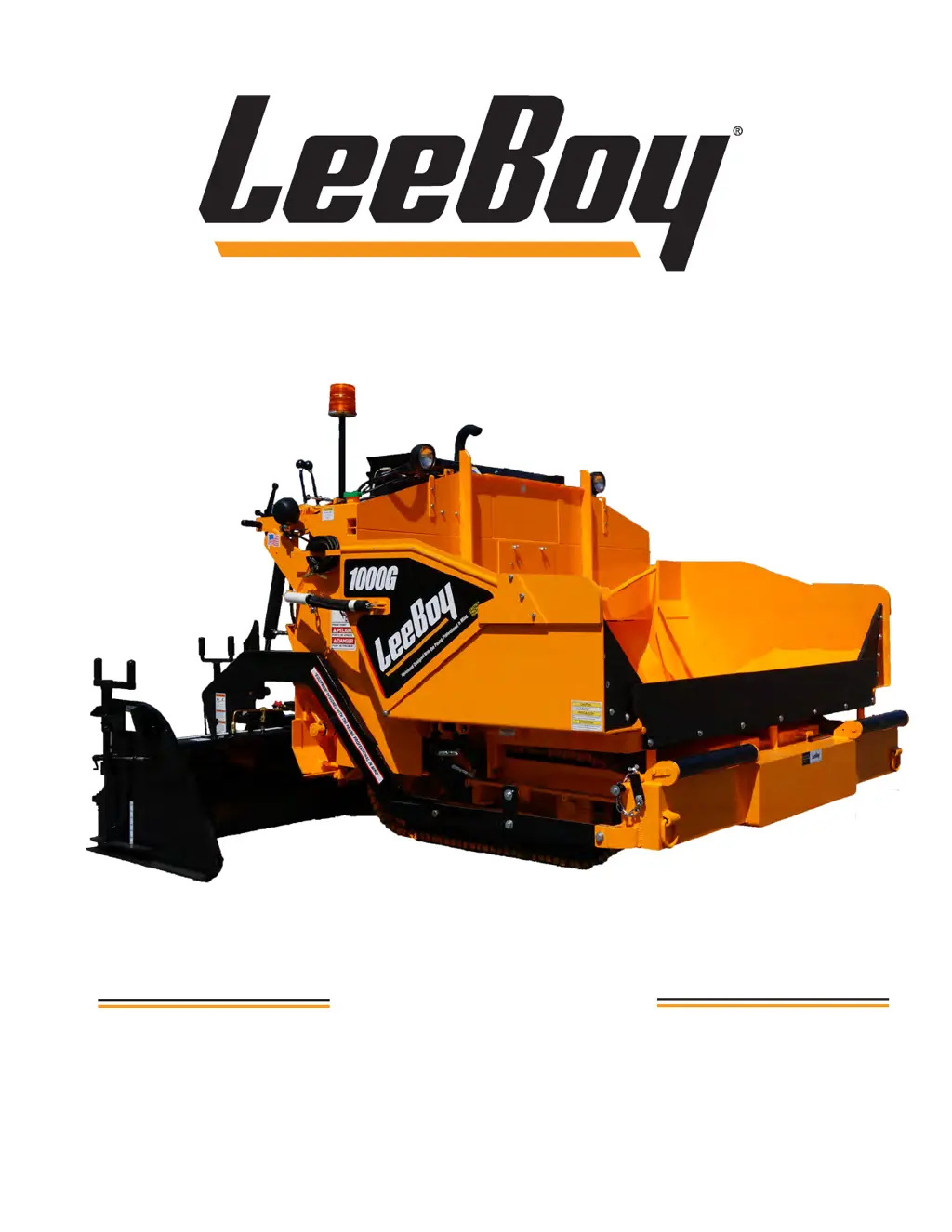

If the light blinks twice, stops, then blinks 9 more times, ensure the connection from the engine ECU is intact and that the ECM is powered up.