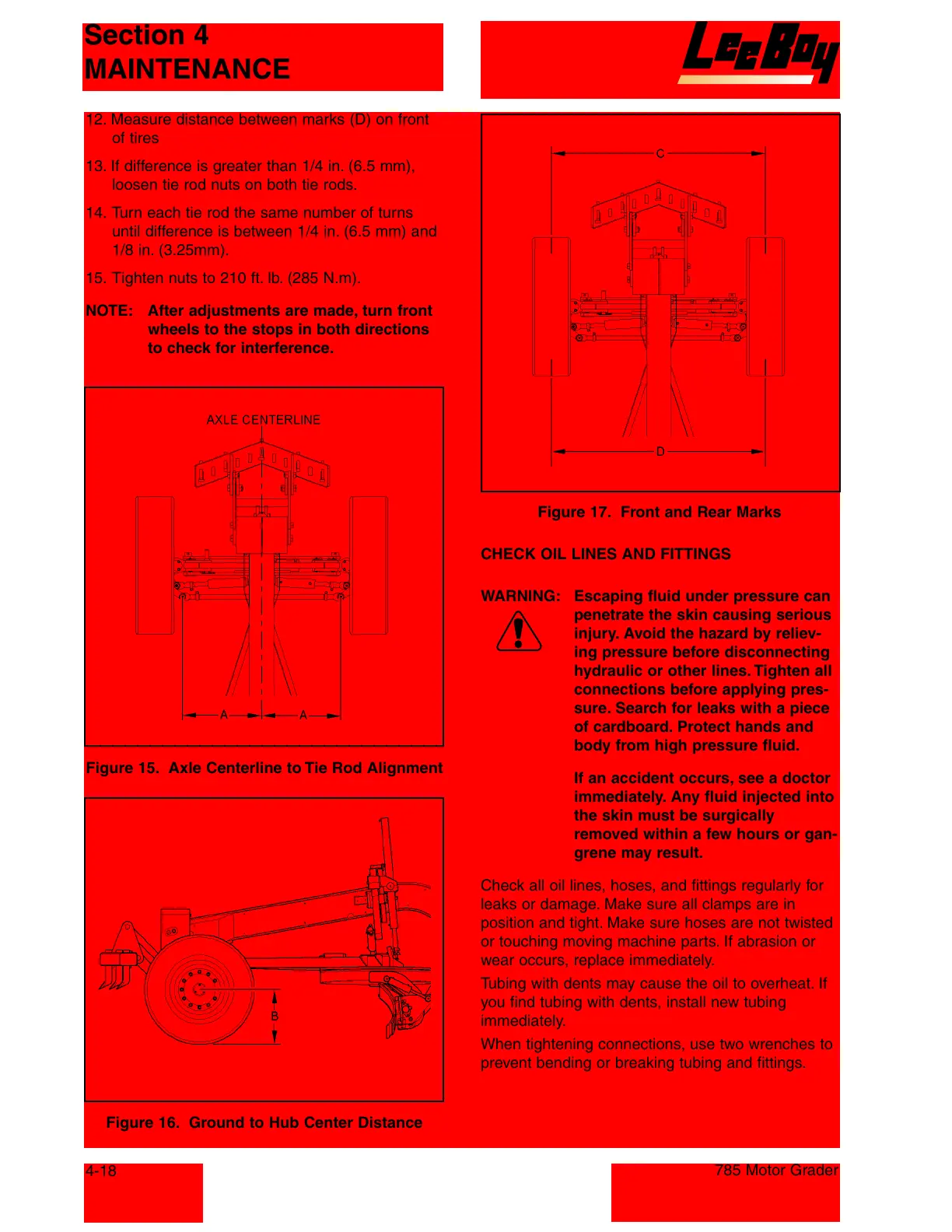

12. Measure distance between marks (D) on front

of tires

13. If difference is greater than 1/4 in. (6.5 mm),

loosen tie rod nuts on both tie rods.

14. Turn each tie rod the same number of turns

until difference is between 1/4 in. (6.5 mm) and

1/8 in. (3.25mm).

15. Tighten nuts to 210 ft. lb. (285 N.m).

NOTE: After adjustments are made, turn front

wheels to the stops in both directions

to check for interference.

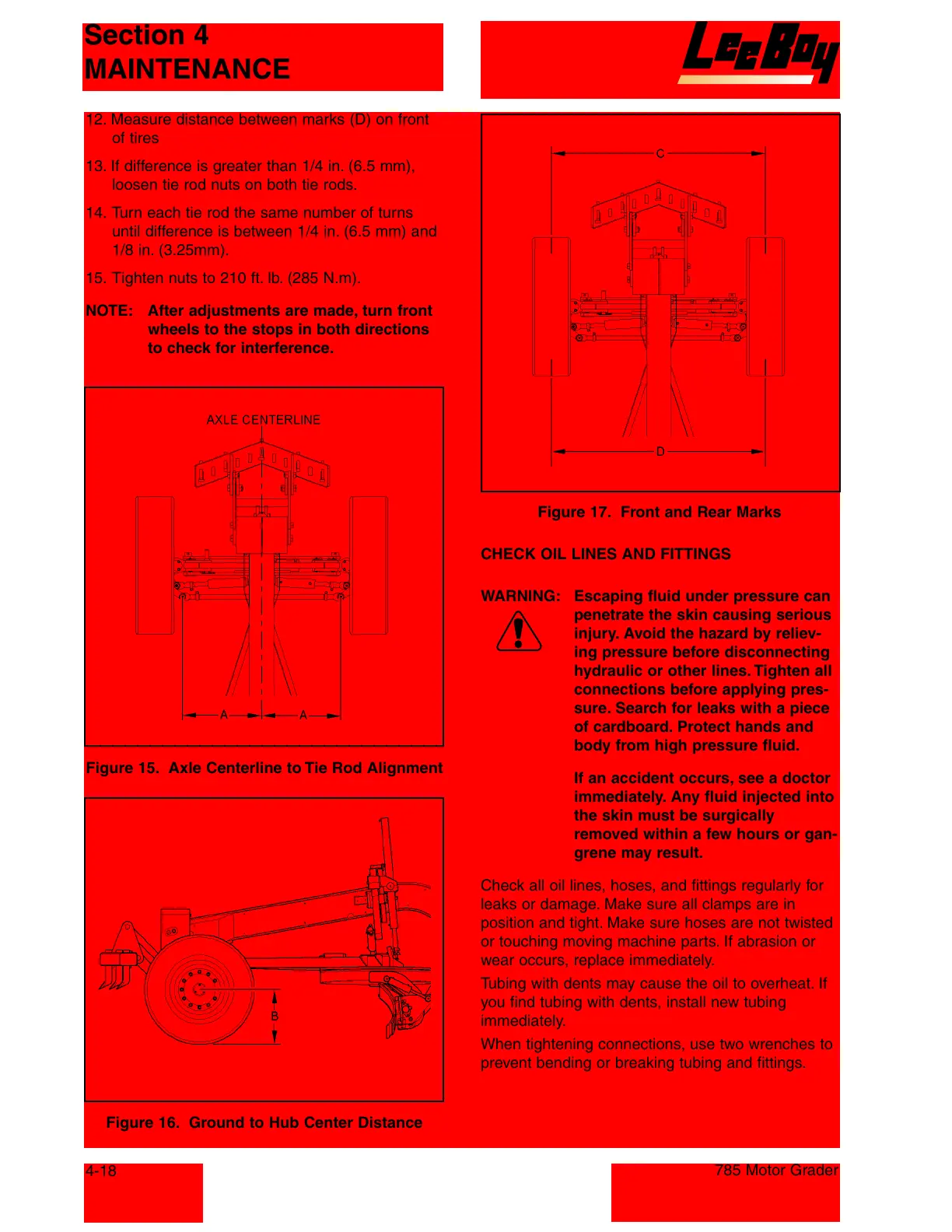

Figure 15. Axle Centerline to Tie Rod Alignment

Figure 16. Ground to Hub Center Distance

Figure 17. Front and Rear Marks

CHECK OIL LINES AND FITTINGS

WARNING: Escaping fluid under pressure can

penetrate the skin causing serious

injury. Avoid the hazard by reliev-

ing pressure before disconnecting

hydraulic or other lines. Tighten all

connections before applying pres-

sure. Search for leaks with a piece

of cardboard. Protect hands and

body from high pressure fluid.

If an accident occurs, see a doctor

immediately. Any fluid injected into

the skin must be surgically

removed within a few hours or gan-

grene may result.

Check all oil lines, hoses, and fittings regularly for

leaks or damage. Make sure all clamps are in

position and tight. Make sure hoses are not twisted

or touching moving machine parts. If abrasion or

wear occurs, replace immediately.

Tubing with dents may cause the oil to overheat. If

you find tubing with dents, install new tubing

immediately.

When tightening connections, use two wrenches to

prevent bending or breaking tubing and fittings.

Section 4

MAINTENANCE

4-18

785 Motor Grader

Courtesy of Machine.Market

Loading...

Loading...