A1 9

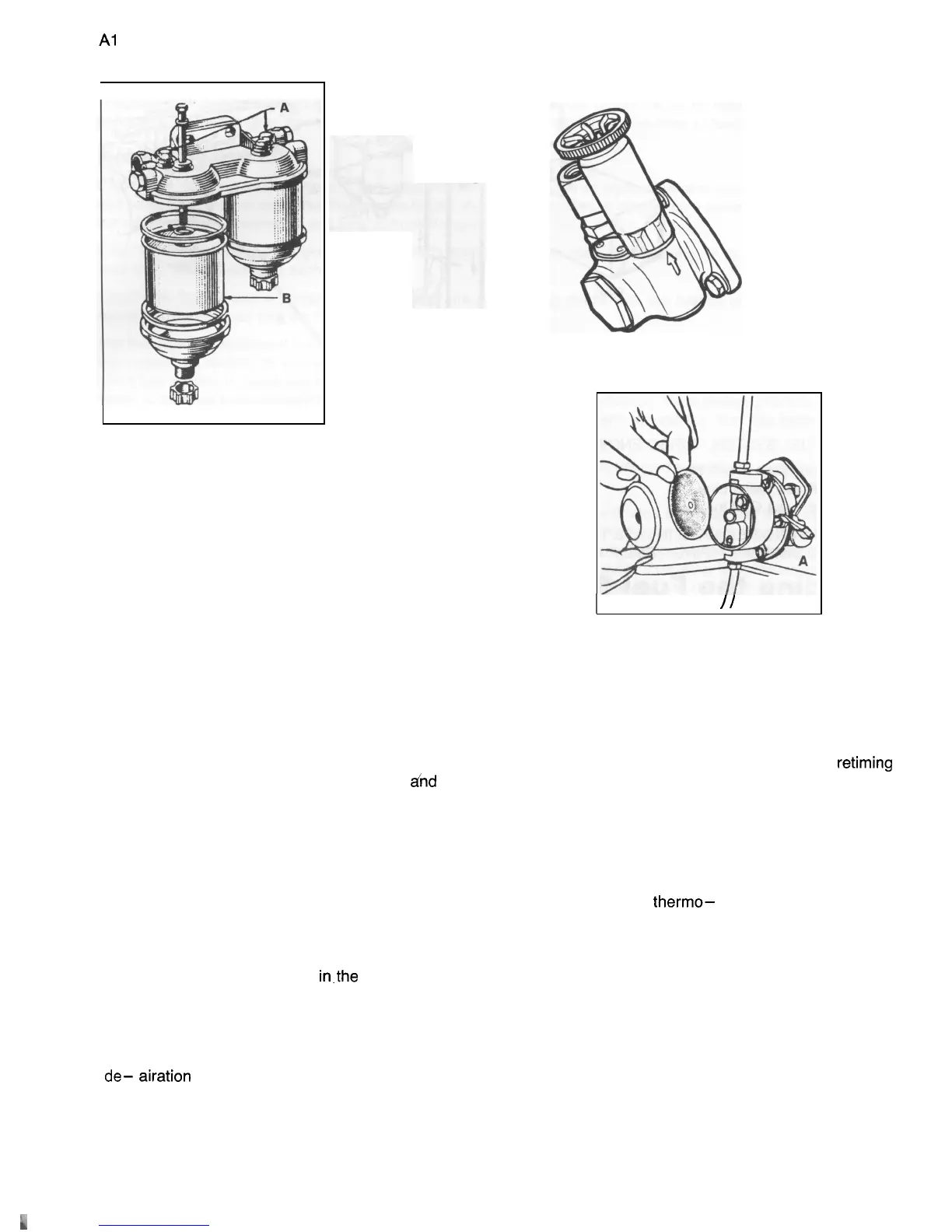

FIG.

5.

FUEL FILTER

A

-

Bleed screws

B

-

Replacable element

FIG.

6.

HIGH PRESSURE LIFT PUMP (ALL TURBO ENGINES)

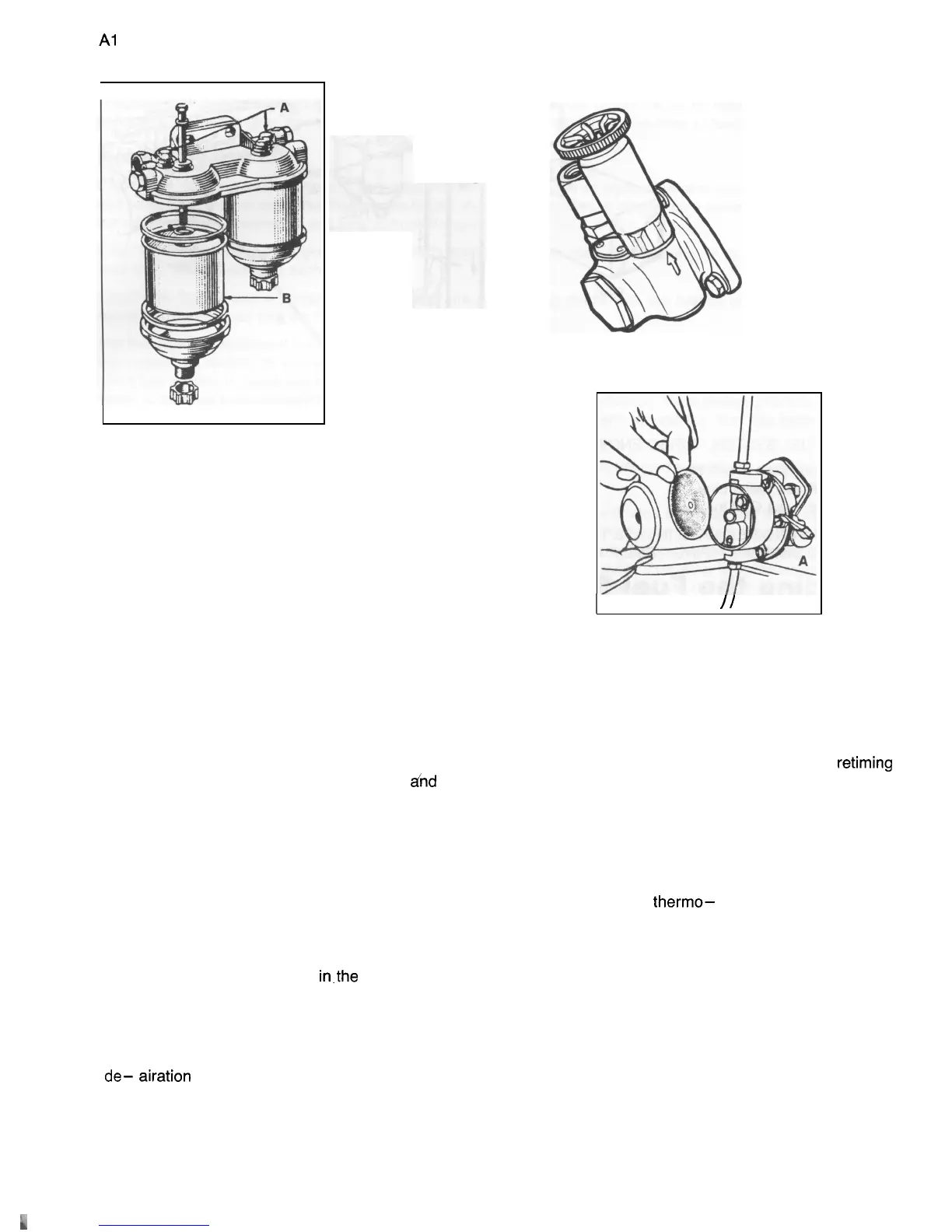

FIG.

7.

I

/J

FUEL LIFT PUMP

-

(ALL N.A. ENGINES)

A

-

Priming lever

Timing and Maintaining

the

Fuel Injection Pump

The injection pump delivers an accurately metered quantity of fuel to each cylinder

to

suit any engines speed and

load conditions. The pump is a very accurately machined piece of equipment and requires careful handling and

maintenance, which is beyond the scope of normal owner servicing. Since this pump should not require

retiming

except when being removed and reinstalled, dnd this is beyond the scope of normal owner servicing, the procedure

will not be covered in this manual. Please contact your authorized Lehman Power distributor for this service.

Warranty claims resulting from owner mishandling of the fuel injection pump will not normally be considered.

Cooling System

Your engine is cooled by the circulation of fresh water (contained in the system) through the water jackets surrounding

the cylinders, cylinder head and exhaust manifold. The heated water flows by

thermo- syphonicaction, assisted

by a pump at the front of cylinder block around the tubes of a “heat exchanger” located above the fuel lift pump on

the starboard side

of

the engine. Raw water from outside the boat flows through the heat exchanger tubes, and

the heat from the fresh water is thus transferred to the raw water which is expelled overboard. Please see Figures

8

and 9. A Thermostat located in.the cylinder head under the expansion tank on naturally aspirated units and in a

separate unit on the starboard side of the turbo charged units promotes rapid warm up and maintains constant

engine temperatures.

The fresh water system is filled through a cap atop the expansion tank at front

of

engine. Water level should be

checked daily and maintained

to

the top of the aluminium pillar. These engines are fitted with a cooling system

de- airation service and no bleeding of the manifold is required during system filling.

When filling cooling system, fill

to

top of aluminium pillar, then run engine for several minutes

to

insure system is

completely filled. Add coolant as necessary.

Loading...

Loading...