1428

Rotate the engine and following the sequence in the following table, adjust each of the remaining valves. Replace

rocker cover, making certain that gasket is unbroken and correctly positioned. After running engine for a short while,

check rocker arm cover gasket for possible oil leaks.

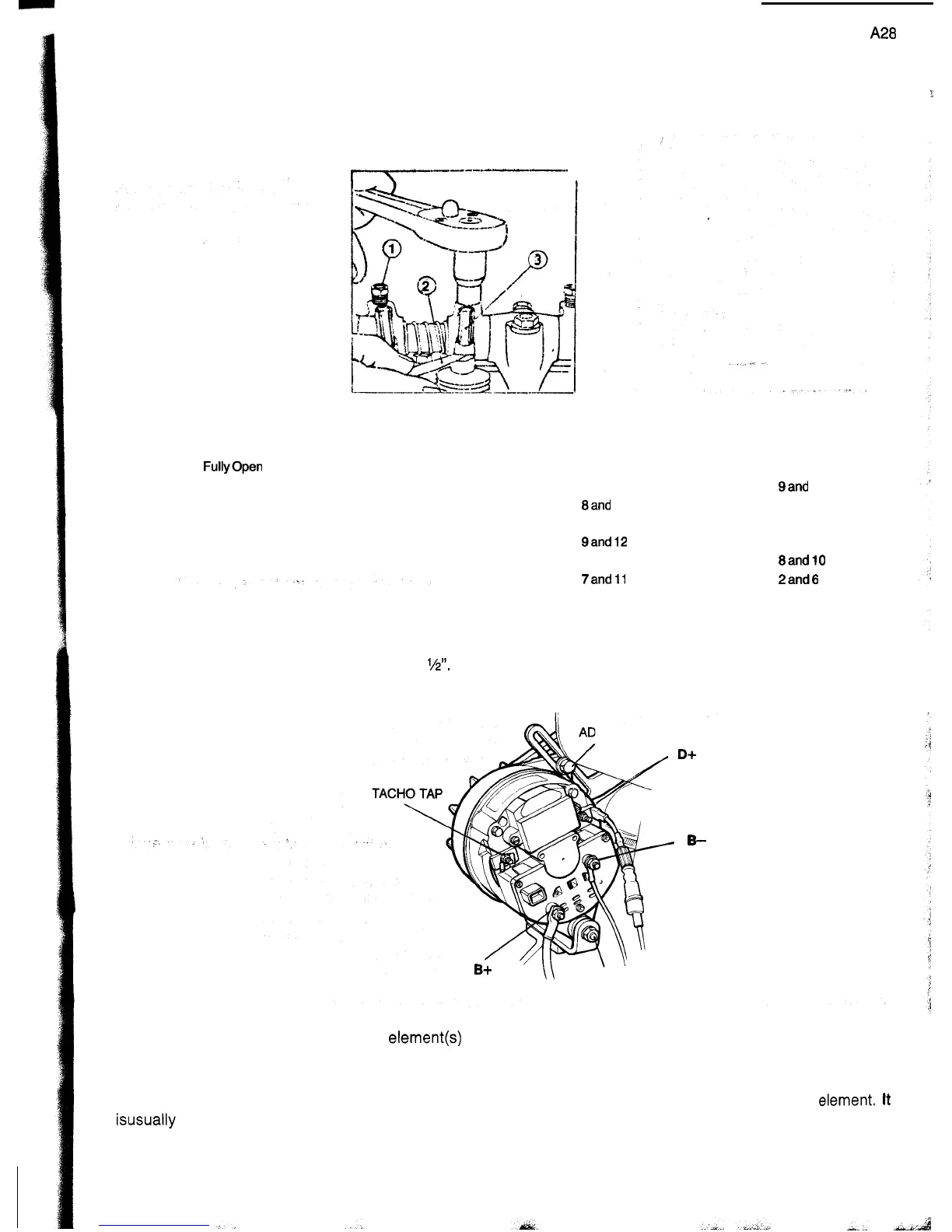

FIG.

18.

ADJUSTING VALVE CLEARANCE

1. Adjusting screw

2. Feeler blade

3.

Rocker arm

----I------

1

4

Cylinder engines

Valves Fullyopen Valves

to

Adjust

1

and6

3

and

8

2 and 4

5

and 7

3

and

8

1

and6

5

and

7

2

and 4

6

Cylinder engines

1

and4 Sand 12

8and 10

3

and

5

7 and

1

2

and 6

9and12

1

and4

3

and

5

8andlO

7andll

Valves Fully Open Valves

to

Adjust

2and6

.

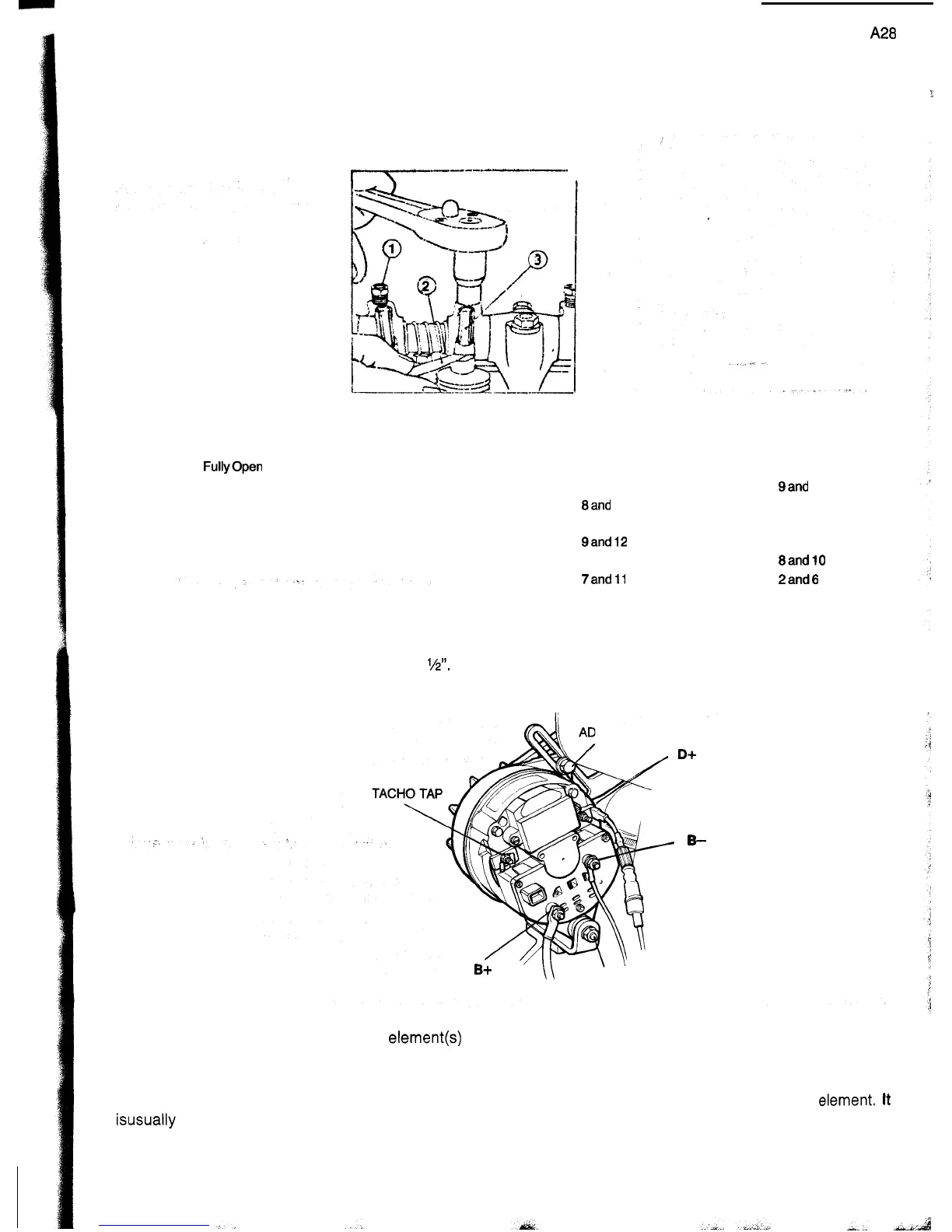

TO

ADJUST VEE BELT TENSION: Loosen alternator mounting and adjusting strap bolts

as

per figure

19.

Move

alternator

to

adjust belt tension. Tension is correct when your thumb pressure on belt at a point between alternator

or and water pump pulleys does not exceed

1h”.

Tighten alternator mounting and adjustment strap bolts.

I

FIG.

19.

BELT ADJUSTMENT

JUSTING STRAP BOLT

D+

B-

B+

MOUNTING BOLTS

INTAKE

AIR

FILTER: The air filtering element(s) on all naturally aspirated engines is polyurethane

foam

which

traps and holds dust and foreign matter which could be drawn into the engine and cause severe damage. Turbo

Charged and Turbo lntercooled engines only use a Mesh Screen.

By reason

of

the efficiency of the filter in trapping contaminants

it

is difficult

to

effectively clean the element.

It

isusually best

to

replace this low

-

cost item as occasion demands. Simply slide old element off its retaining screen

and carefully stretch a new element into position. If cleaning is desired, wash in a mild detergent mixed in clear,

sweet water.

DO

NOT wash in mineral spirits, varsol, gasoline, or any petroleum product.

Loading...

Loading...