R-

A29

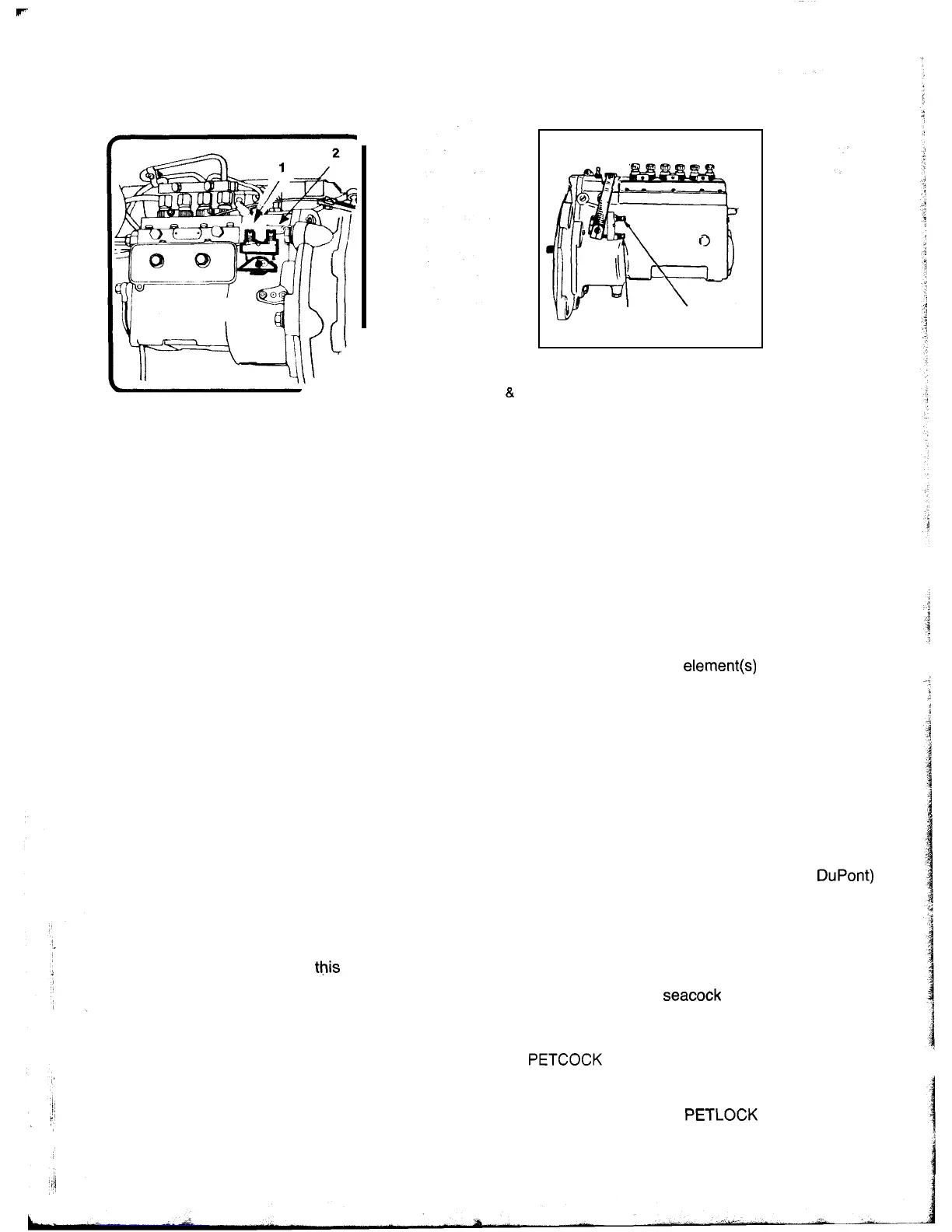

FIG.

20

INJECTION PUMP (All N.A. ENGINES)

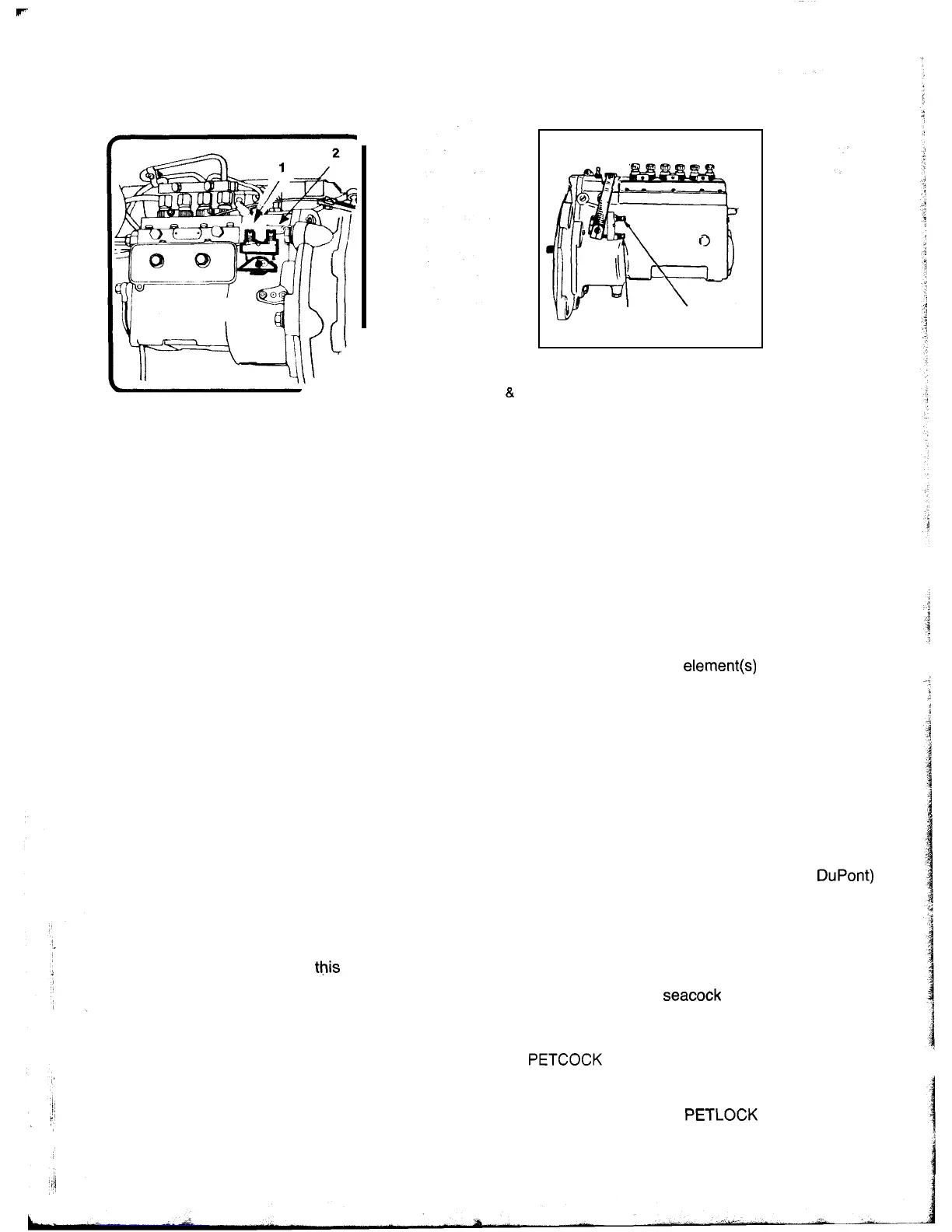

ll

INJECTION PUMP (TURBO ENGINES)

1

2

I

1.

Max

speed

stop

screw

2.

Idling

stop

screw

&

locknut

TO ADJUST IDLING SPEED: When properly serviced and after the initial “break

-

in” period, your engine should

idle as indicated on spec sheet.

Engine must be at normal operating temperature when making adjustments. With engine running, loosen the idle

screw locknut which

is

on side of fuel injection pump. Adjust the idle speed screw until eingine is idling at correct

speed and then tighten locknut. Operate the throttle lever to make certain that same returns to same setting.

Note:

If

engine is new or cold, it may idle unevenly. Do not increase the idle speed setting to compensate. ON NO

ACCOUNT SHOULD THE MAXIMUM SPEED STOP BE CHANGED.

TO

CLEAN FUEL LIFT PUMP Turn

off

fuel supply valve. Holding receptacle under pump to prevent spilling of fuel

into bilge of boat, loosen the center bolt and remove cover and pulsator. Clean pump thoroughly and wash cover

and pulsator in fuel oil. Replace parts carefully.

It

will be necessary to bleed fuel system. Check for possible leaks

after starting engine.

TO CHANGE SECONDARY FUEL FILTERS (note

-

making certain that the filter element(s) you will

use

is an

EXACT replacement for the element you will remove, otherwise, air leaks into the fuel system may result. Unscrew

the securing bolts on top of filter housing and remove filter bowls and elements. Discard elements and upper and

lower sealing rings. Wash out the bowls and clean fuel oil but do not use a cloth for remaining lint may clog the

fuel system. Carefully fit new sealing rings to the filter heads and bowls, assemble to the filter heads and replace

and tighten securing bolts. It will now be necessary to bleed the fuel system of air as described in separate section.

After running engine for a short time, check filters for possible fuel leaks.

Winterizing

In preparation for freezing temperatures, anti

-

freeze should be provided in the fresh water system

of

your engine.

Due to the high temperature of operation a high boiling point anti

-

freeze is demanded. Do not attempt to use alcohol

or other non

-

permanent types and do not use any liquids containing “sealants”. Zerex (produced by DuPont) is

highly recommended. Consult the specification freeze to bring within the limits of expected temperatures. Inboard

type heat exchangers and oil coolers must be drained of raw (sea) water when exposed to freezing temperatures.

Drain plugs

will

be found on bottom of heat exchanger and oil coolers and should be removed until all water has

been drained. Raw water pump may be drained by loosening screws holding rear cover in position. Please refer

to

“cooling system” section of

this

manual for alternate winterizing method.

If

boat is to remain in water while draining engine, of course, the intake water seacock must be closed prior

to

draining.

Do

not neglect to open sea

-

cock prior to starting engine.

NOTE: TO DRAIN FRESH WATER, REMOVE WATER FILLER CAP

FROM

TOP OF EXPANSION TANK ON

FRONT OF ENGINE. DRAIN BLOCK BY OPENING

PETCOCK ON PORT (LEFT) SIDE OF ENGINE IN

CENTER, LOWER SECTION. REMOVE PLUG

ON

UNDERSIDE OF HEAT EXCHANGER (THE ONE

NEARESTCENTER OF EXCHANGER) TO DRAIN WATER FROM EXCHANGER, EXPANSION TANK AND

EXHAUST MAINFOLD. REPLACE FILL CAP ON TANK AFTER CLOSING

PETLOCK AND INSTALLING

PLUG IN HEAT EXCHANGER.

Loading...

Loading...