Page 83

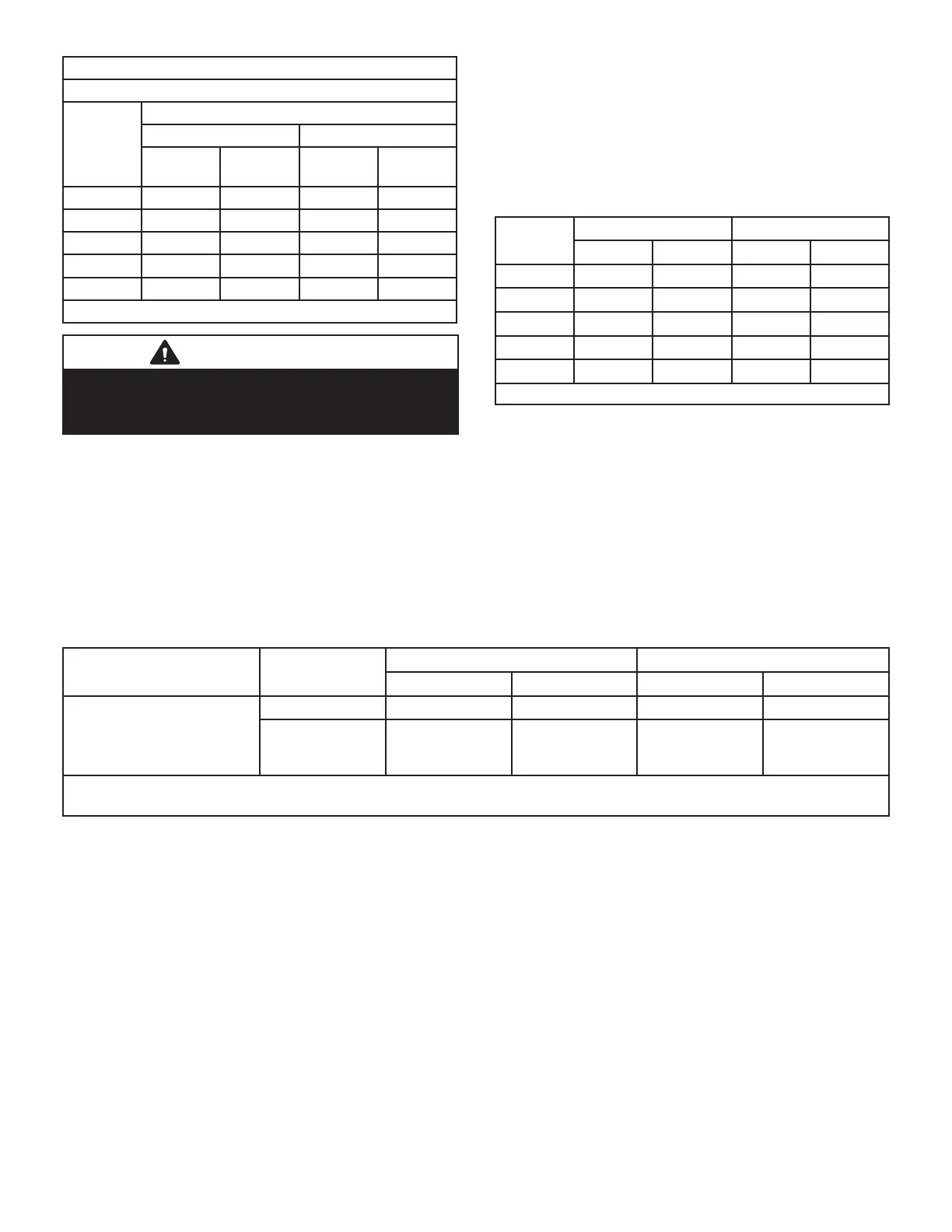

TABLE 28

GAS METER CLOCKING CHART

EL296

Unit

Seconds for One Revolution

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

Dial

-045 80 160 200 400

-070 55 110 136 272

-090 41 82 102 204

-110 33 66 82 164

-135 27 54 68 136

Natural-1000 btu/cu ft LP-2500 btu/cu ft

IMPORTANT

For safety, shut unit o and remove manometer as

soon as an accurate reading has been obtained.

Take care to replace pressure tap plug.

G- Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas ow rate before checking com-

bustion. See sections E- and F-. Take combustion sample

beyond the ue outlet. TABLE 29 shows acceptable com-

bustions. The maximum carbon monoxide reading should

not exceed 100 ppm.

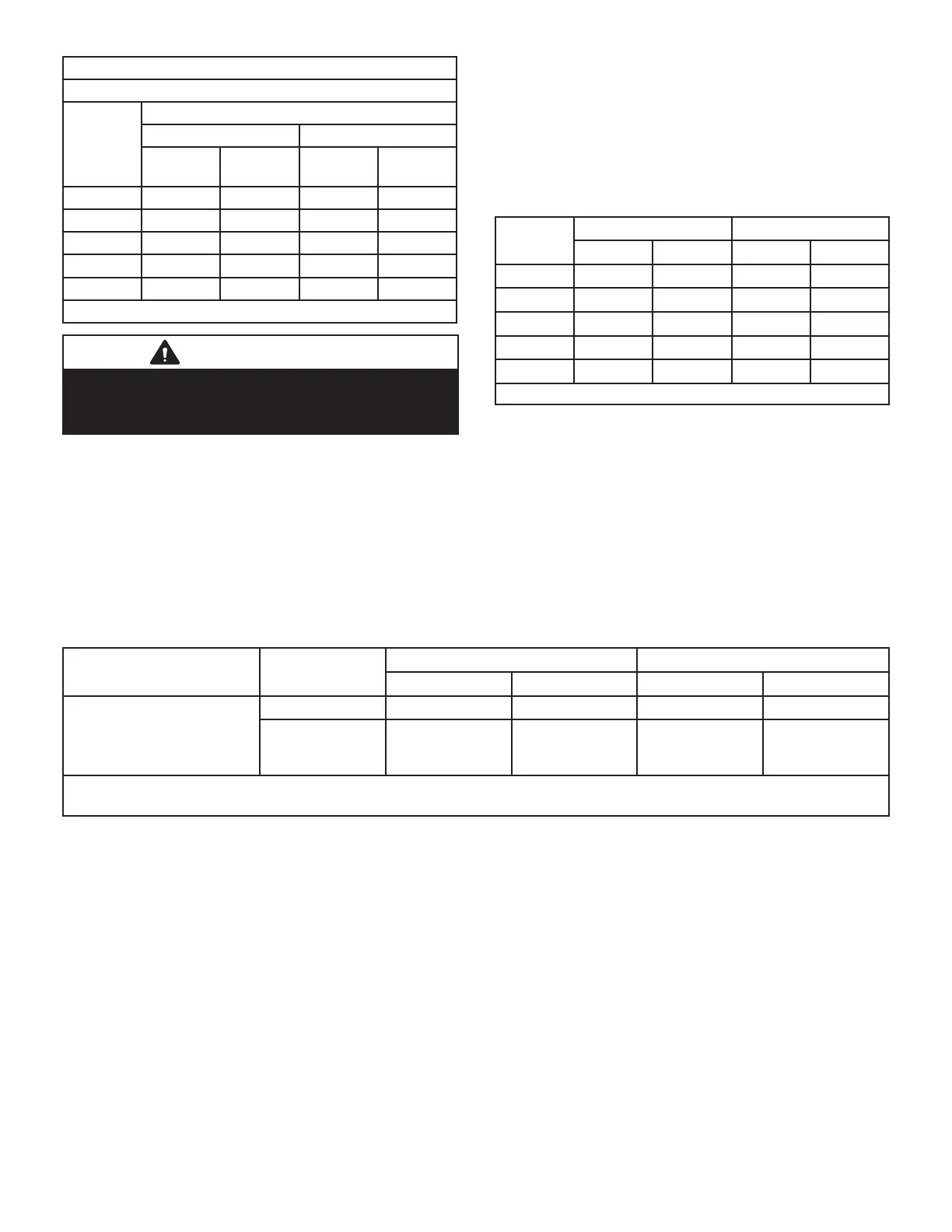

TABLE 29

EL296

Model

CO

2

% For Nat CO

2

% For L.P

Low Fire High Fire Low Fire High Fire

045 5.4 - 6.4 7.5 - 8.5 6.4 - 7.4 8.8 - 9.8

070 5.3 - 6.3 7.4 - 8.4 6.3 - 7.3 8.7 - 9.7

090 5.8 - 6.8 7.6 - 8.6 6.8 - 7.8 8.9 - 9.9

110 6.1 - 7.1 8.0 - 9.0 7.1 - 8.1 9.3 - 10.3

135 6.1 - 7.1 7.8 - 8.8 7.1 - 8.2 9.1 - 10.1

The maximum carbon monoxide reading should not exceed 100ppm.

H- High Altitude

The manifold pressure, gas orice and pressure switch

may require adjustment or replacement to ensure proper

operation at higher altitudes. See TABLE 30 or TABLE 31

for manifold pressures. See TABLE 32 for gas conversion

and pressure switch kits.

TABLE 30

Manifold and Supply Line Pressure 0-10,000ft.

EL296UH Unit Gas

Manifold Pressure in. wg. Supply Line Pressure in. wg.

Low Fire High Fire Min Max

045, 070

-1 through -5 Units

090, 110, 135

-1 through -4 Units

Natural 1.7 3.5 4.5 13.0

LP/Propane 4.5 10.0 11.0 13.0

NOTE - A natural to L.P. propane gas changeover kit is necessary to convert this unit. Refer to the changeover kit installation instruction for the

conversion procedure.

Loading...

Loading...