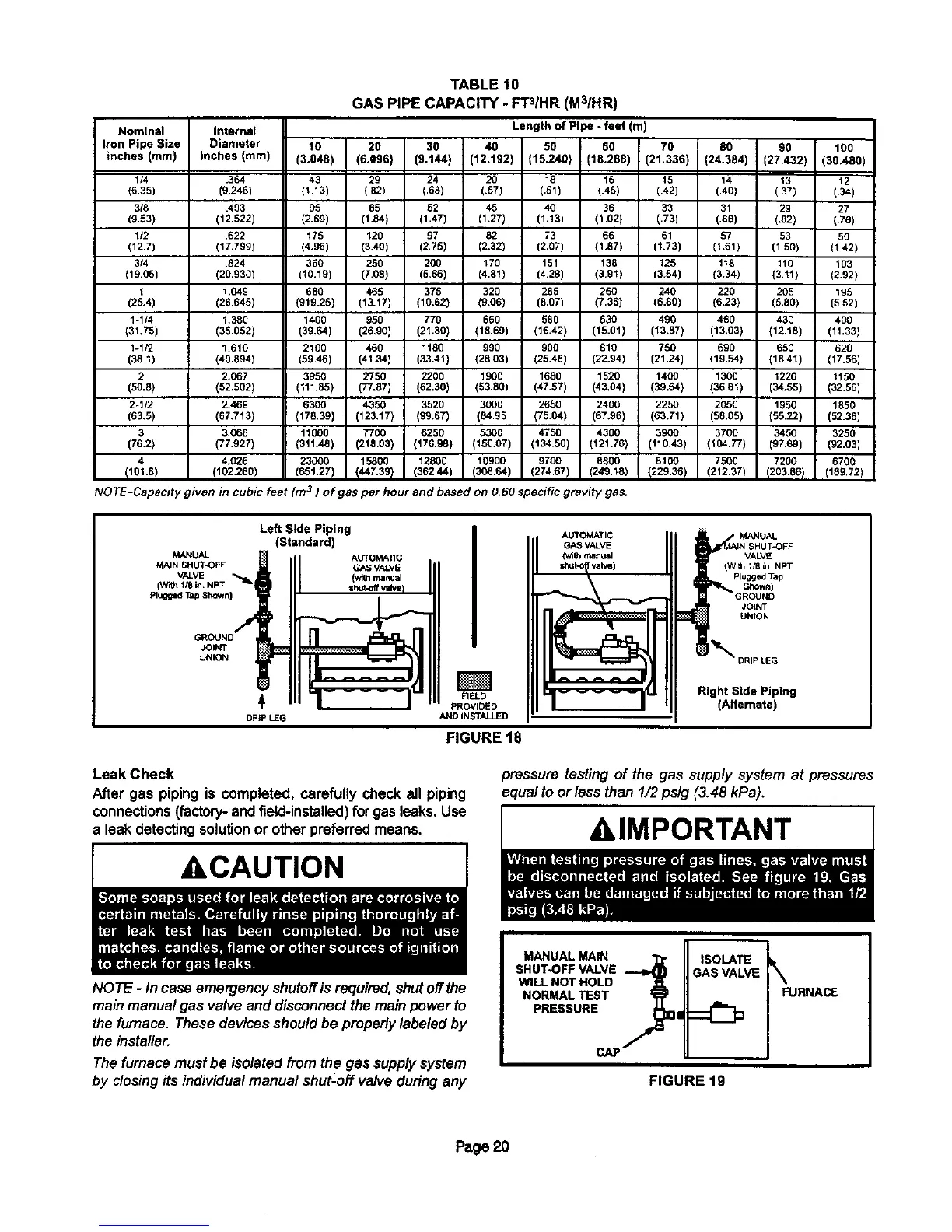

TABLE 10

GAS PIPE CAPACITY - FT3/HR (M3/HR)

Nominal Internal

Iron Pipe Size Diameter 10 20 30 i 40

inches (mm) inches (mm) (3.048) (6.096) (9.144) I (12.192

1/4 .364 43 29 24 20

(6.35) (9.246) (1113) (.52) (,65) (.57)

3/8 .493 96 65 52 45

(9.53) (12.522) (2.69) (t.84) (1.47) (1.27)

112 .622 175 t20 97 82

(12.7) (17.799) (4.95) (3.40) (2,75) (2.32)

3/4 .524 360 250 200 170

(19.05) (20.930) (10.t9) (7.08) (5,66) (4,81)

1 1.049 680 465 375 320

(25,4) (26.645) (919.25) (13.t7) (10.62) (9,06)

1-1/4 1,380 1400 950 770 660

(31.75) (38.052) (39.64) (26,90) (21.80) (18.69)

1-1/2 1.610 2100 460 tt80 990

(38,1) (40.894) (59A6) (41.34) (33,41) (26,03)

2 2,067 3950 2750 2200 1900

(50.8) (52.502} (111.85) (77,67) (62,30) (53,80)

2-1/2 2,469 6300 4350 3520 3000

(63,5) (67.713) (176.39) (123,17) (99.67) (84.95

3 3,068 11000 7700 6250 5300

(76.2) (77.927) (311.46) (216.03) (176.98) (150.07)

4 4.026 23000 15800 12800 10900

(101.6) (102.260) (65t.27) (447.39) (362,44) (308.64)

Length of Pipe - feet (m)

80 60 70 00 90 100

(15.240) (18.288) (21,336) (24.384) (27,432) (30.480)

18 16 15 14 13 12

(.51) (.45) (.42) (,40) (.37) (.34)

40 36 33 31 29 27

(1.13) (1.02) (.73) (.88) (,82) (.76)

73 66 61 57 53 50

(2.07) (1,87) (I,73) (1.61) (150) (1.42)

151 138 125 118 110 103

(4.28) (3.91) (3.54) (3,34) {3.11) (2.92)

285 260 240 220 205 195

(8,07) (7.36) (6.80) (623) (5.80) (5.52)

580 530 490 460 430 400

(16.42) (15.01) (13.87) (13.03) (12.18) (11.33)

900 810 750 690 650 620

(25,48) (22.94) [21.24) (19,54) (18.41) (17.56)

1680 1520 1400 1300 1220 1150

(47.57) (43,04) (39.64) (36,01) (34.55) (32,56)

2650 2400 2250 2050 1950 1850

(75.04) (67.96) (63.71) (58.05) (55,22) (52.38)

4750 4300 3900 3700 3450 3250

(134.50) (121.76) (110.43) (104.77) (97.69) (92.03)

9700 8600 8100 7500 7200 6700

(274,67) (249.13) (229,36) (212,37) (203,88) (189.72)

NOTE-Capacity given 3in cubic feet (m ) of gas per hour and based on O,6Ospecific grav_tygas.

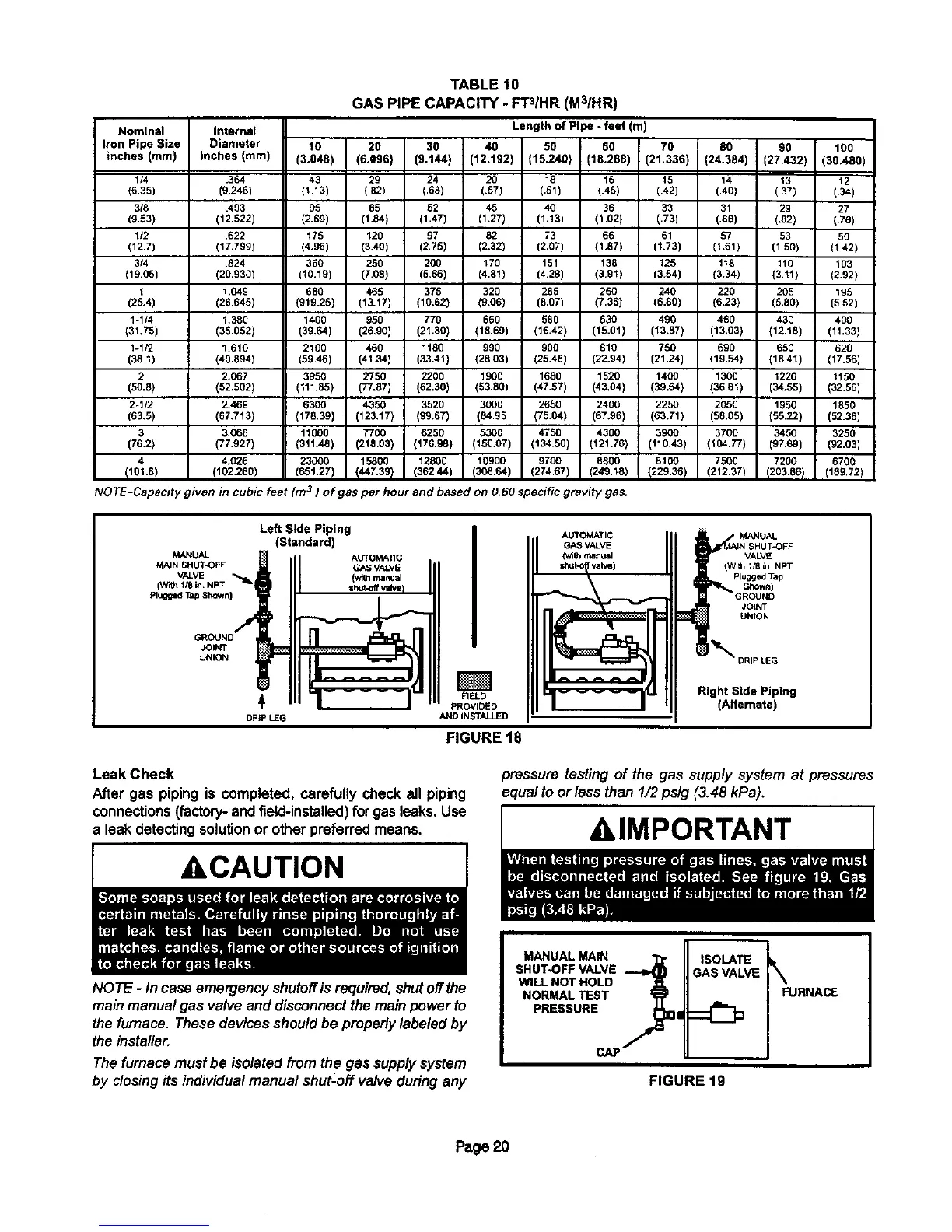

MANUAL

MAIN SHUT-OFF

VALVE

(With I/6 _n.NPT "_I

Plugged Tap Shown)

JOINT

UNION

Left Side Piping

(Standard)

AUTOMATIC

GASVALVE

(v_t=manual

DRIPLEG

AUTOMATIC

GASVALVE

(withmanusl

valvai

FIELD

PROVIDED

ANDINSTALLED

FIGURE 18

MANUAL

VALVE

Plugged Tap

Shown)

JOLNT

UNtON

_DRIP LEG

Right Side Piping

(Alternate)

Leak Check

After gas piping is completed, carefully check all piping

connections(factory-andfield-installed) forgasleaks.Use

a leak detectingsolutionor otherpreferredmeans.

ACAUTION

NOTE - In case emergency shutoff is required,shutoffthe

main manual gas valveand disconnect the mainpowerto

the furnace. These devicesshouldbe properly labeledby

the installer.

The furnacemust be isolatedfrom the gas supplysystem

by closingits individualmanual shut-off valve duringany

pressure testing of the gas supply system at pressures

equalto or/ess than 1/2psig (3.48 kPa).

AIMPORTANT

MANUAL MAiN

SHUT,OFF VALVE

WILL NOT HOLD

NORMAL TEST

PRESSURE

c/_

ISOLATE

FIGURE 19

Page20

Loading...

Loading...