I AWARNING

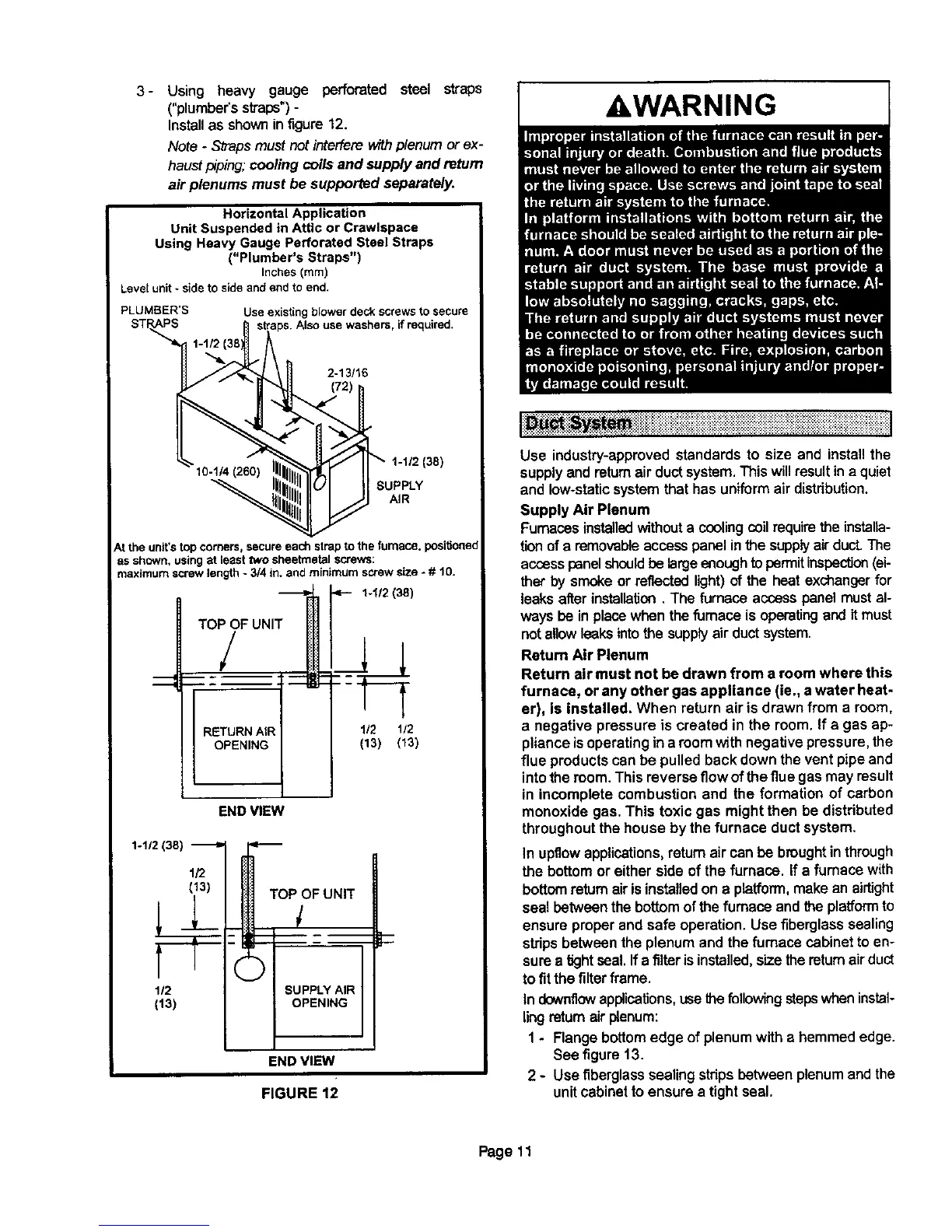

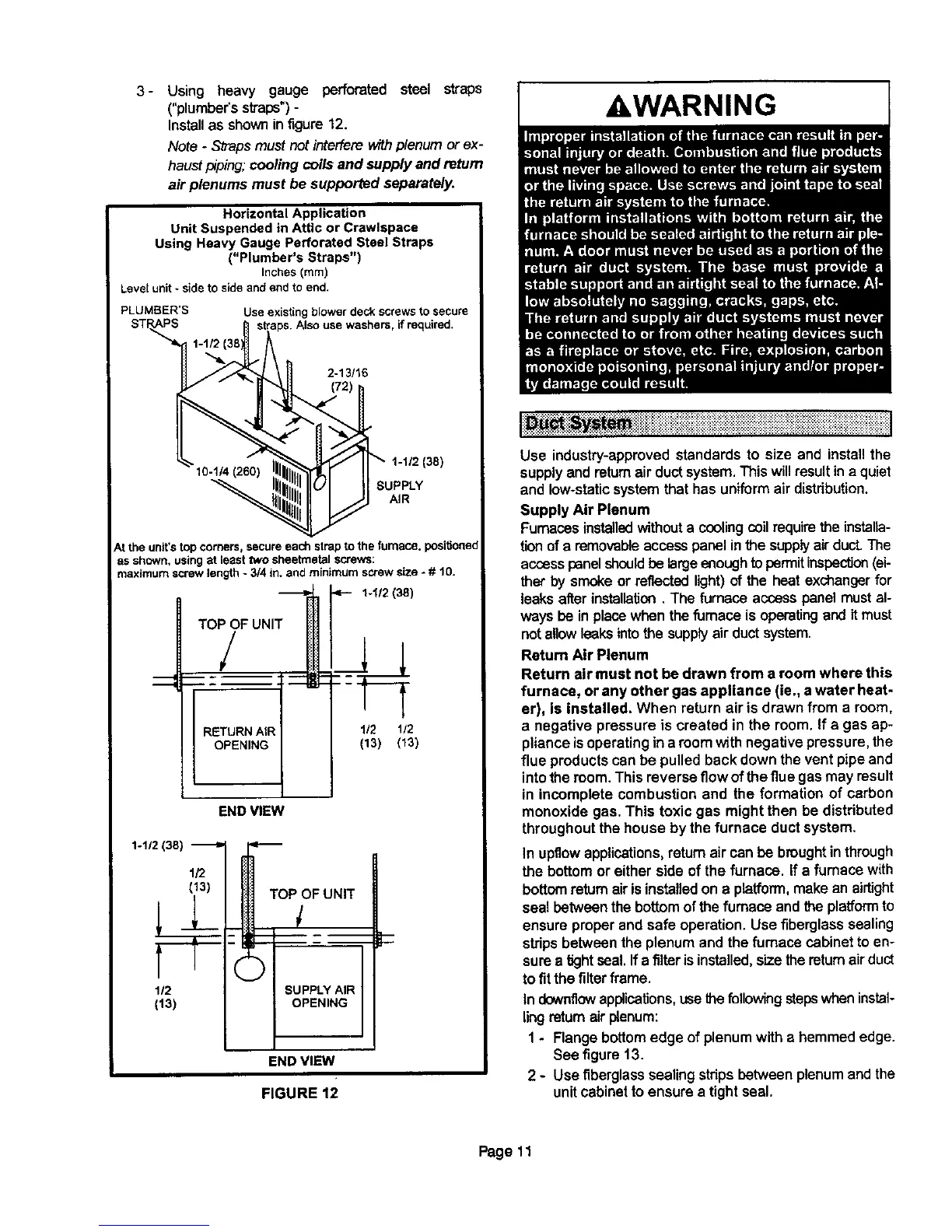

3- Using heavy gauge perforated steel straps

("plumber's straps') -

Install as shown in figure 12.

Note - Straps must not interfere withplenum or ex-

haust I_ping; cooling coils and supply and return

air plenums must be supported separately.

Horizontal Application

Unit Suspended in Attic or Crawlspace

Using Heavy Gauge Perforated Steel Straps

("Plumber's Straps")

Inches (ram)

Level unit - side to side and end to end.

PLUMBER'S

Use existing blower deck screws to secure

Also use washers, if required,

2-13/16

1-1/2 (38)

SUPPLY

AIR

Atthe unit's top corners, secure each strap to the furnace, positJone_

as shown, using st least two sheetrnetal screws:

maximum screw length - 3/4 in. and minimum screw size - # 10.

1-1/2 {38)

TOP OFUNIT

/

RETURN AIR 112 1/2

OPENING (13) (13)

END VIEW

1-1/2 (3S)

1/2

(13) TOP OFUNIT

112 ;UPPLY AIR

(13) OPENING

END VIEW

FIGURE 12

Use industry-approvedstandards to size and installthe

supplyand rstumair ductsystem.This willresultina quiet

and low-staticsystemthat has uniformair distdbution.

Supply Air Plenum

Furnacesinstalledwithouta coolingcoilrequirethe instaUa-

tionof e removableaccesspanel inthe supplyairduct.The

accesspanelshouldbe largeenoughto permitinspection(ei-

ther by smokeor reflectedlight)of the heat exchangerfor

leaks after installation.The furnace access panelmustal-

waysbe in placewhen thefurnace isoperatingand it must

notallowleeksintothe supplyair ductsystem.

Return Air Plenum

Return air must not be drawn from a room where this

furnace, or any other gas appliance (ie., a water heat-

er), is installed. When return air isdrawn from a room,

a negative pressure is created in the room. If a gas ap-

pliance is operating in a roomwith negative pressure, the

flue productscan be pulled back down the vent pipe and

into the room. This reverse flow of theflue gas may result

in incomplete combustion and the formation of carbon

monoxide gas. This toxic gas might then be distributed

throughout the house by the furnace duct system.

In upfiowapplications,returnair canbe brought in through

the bottomor either side of the furnace. If a furnace with

bottomreturnairisinstalledon a platform,makean airtight

seal between the bottomofthe furnace and the platformto

ensureproper and safe operation. Use fiberglasssealing

stripsbetweenthe plenumand the furnace cabinetto en-

sure a tightseal.If a filter isinstalled,sizethereturnair duct

tofit thefilterframe.

In downfiow applications,usethe followingsteps when instal-

ling rstum air plenum:

1 - Flange bottom edge of plenum with a hemmed edge.

See figure 13.

2 - Use fiberglass sealing strips between plenum endthe

unit cabinet to ensure a tight seal.

Page 11

Loading...

Loading...