HeatingSequenceOfOperation

1- Whenthermostatcallsforheat,combustionairblower

starts.

2 - Combustion air pressure switch proves blower opera-

tJon.Switch is factory set and requires no adjustment.

3 - After a 15 second prepurge, hot surface ignitor ener-

gizes.

4 - After a 20 second ignitor warm-up period, gas valve

solenoid opens.

5 - Gas is ignited, ignition sensor proves the flame and

combustion process continues.

6 - If flame is not detected after first ignition tdat, ignition

controlwillrepeat steps3 and4 fourmoretimesbefore

lockingoutthe gasvalve ("WATCHGUARD"flame fail-

ure mode). Ignitioncontrolwill then automaticallyre-

peat steps3, 4, 5 and 6 after 60 minutes,

7- To interruptthe 60-minute °WATCHGUARD" pedod,

move thermostat_om "Heat" to "OFF" then back to

"Heat." Heatingsequencethen restartsat step f.

: • :. . • . . :::_ • : . ,: :::_:_:: _:::::: ;}::;:_::: :::::: ;_:1;'_:_:::::

Gas Flow

Tocheck for propergasflow to thecombusf_onchamber,de-

terrninethe Bto(kW)klputfrom the unit ratingplate.Dividethis

inputraSngby theBtu (kW) per cubicfoot (cubicmeter)of

availablegas,The resultis therequirednumberof cubic feet

(cubicmeter)perhour.Determinetheflowof gas throughthe

gas meterfor two minutesend multiplyby 30 to getthe houdy

flowof gas.

Gas Pressure

1 - Check the gas line pressure withthe unitfiringat maxi-

mumrate.A minimum of 4.5 in.w.c.for naturalgas or

11.0in.w.c,forLP/prepanegasshouldbe maintained.

2- After the line pressure has been checked and ad-

justed, check the regulator pressure. Manifold pres-

suresare givenin table 11. See figures23 and 24 for

manifoldpressureadjustmentscrewlocation.

Note - A natura! gas to LP/propane gas changeover kit is

requiredto convert theunit.

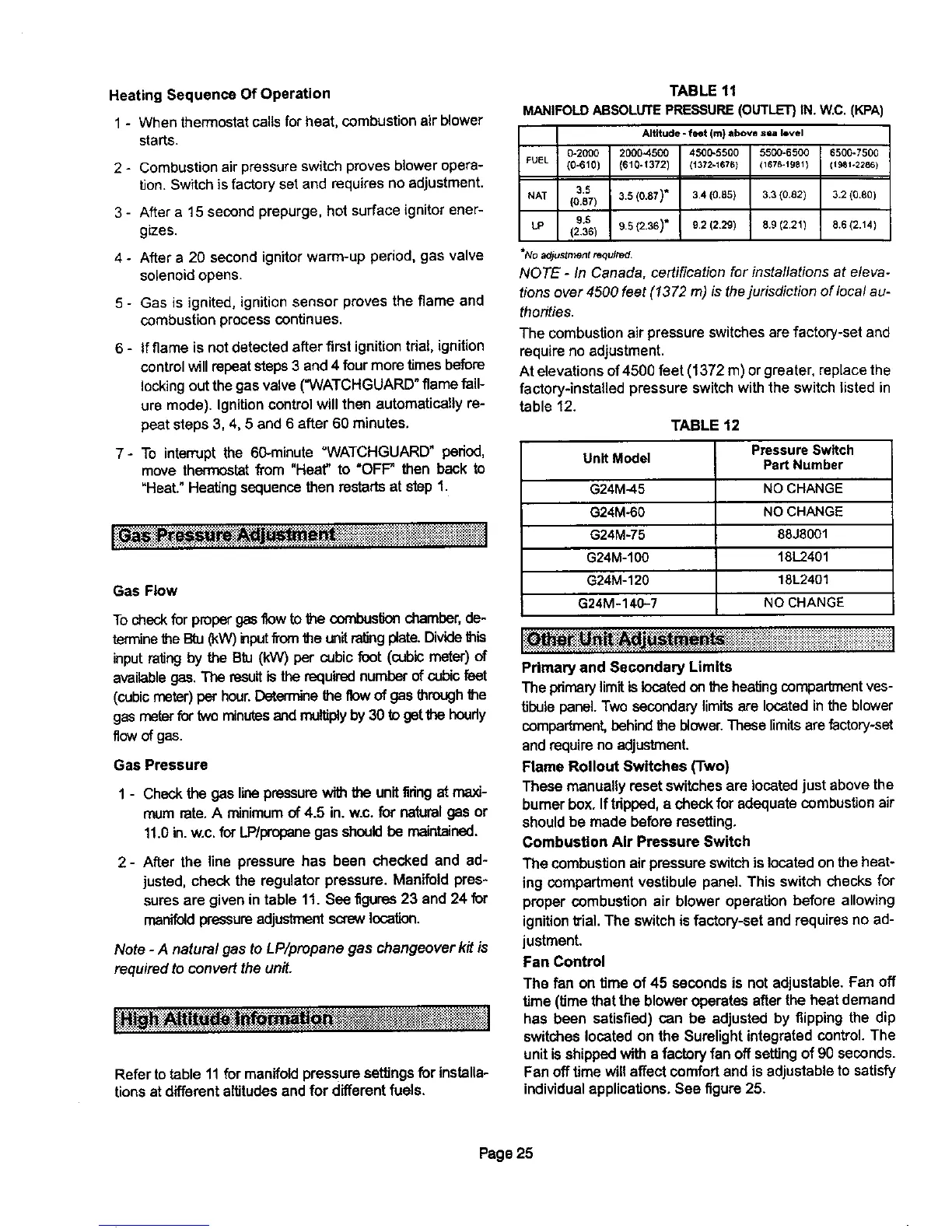

Refer totable 11 for manifoldpressure settingsfor installa-

tionsat differentaltitudesandfor differentfuels.

TABLE 11

MANIFOLDABSOLUTEPRESSURE(OUTLET}IN. W,C,(KPA)

Altitude -feet (m) above sia level

0-2000 2000-4500 4500-5500 5500-6500 6500-7500

FUEL (0-610) (610-1372) (1372-1676) (1676-1981) (1981÷2286)

3.5 3.5 (0,87)* 3.4 (0.85) 3,3 (0.82) 3.2 (0.80)

NAT (0.87)

6.6 6.5 (2.36)" 92 (2/29) 8,9 (221) 8.6 (2.14)

LP (2.36)

*No adjustment required.

NOTE - In Canada, certification for installations at eleva-

tions over 4500 feet (1372 m) is the jurisdiction of local au-

thorities.

The combustion air pressure switches are factory-set and

require no adjustment.

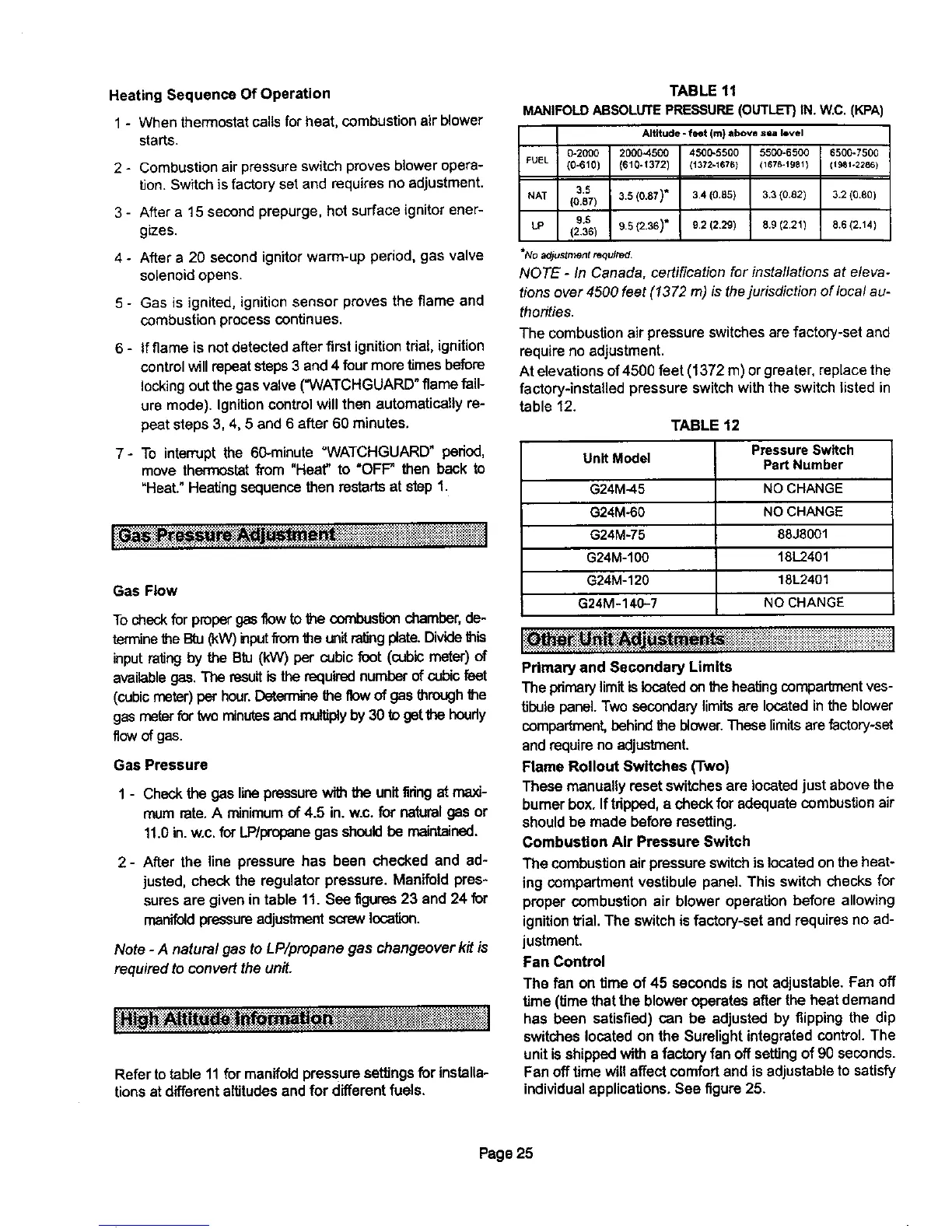

At elevations of4500 feet (1372 m)or greater, replace the

factory-installed pressure switch with the switch listed in

table 12.

Unit Model

G24M-45

G24M-60

G24M-75

G24M-100

G24M-120

G24M-14_?

TABLE 12

Pressure Switch

Part Number

NO CHANGE

NO CHANGE

88J8001

18L2401

18L2401

NO CHANGE

Primary and Secondary Limits

The primarylimitis locatedon theheatingcompadmentves-

tibulepanel.Two secondarylimitsere locatedinthe blower

compartment,behind the blower.Theselimitsarefactory-set

andrequire no adjustment.

Flame Rollout Switches (Two)

These manuallyresetswitchesare locatedjust abovethe

burnerbox. Iftdpped,a check for adequatecombustion air

shouldbe made before resetting.

Combustion Air Pressure Switch

The combustion air pressureswitchis locatedonthe heat-

ing compartmentvestibule panel. This switchchecks for

proper combustion air blower operation before allowing

ignitiontrial,The switchis factory-setand requiresno ad-

justment.

Fan Control

The fan on time of 45 seconds is not adjustable. Fan off

time (time thatthe bloweroperates afterthe heatdemand

has been satisfied) can be adjusted by flippingthe dip

switcheslocated on the Surelightintegratedcontrol.The

unitis shippedwitha factoryfan offsettingof 90 seconds.

Fan off timewillaffect comfortand is adjustableto satisfy

individualapplications.See figure25.

Page25

Loading...

Loading...