Page 21

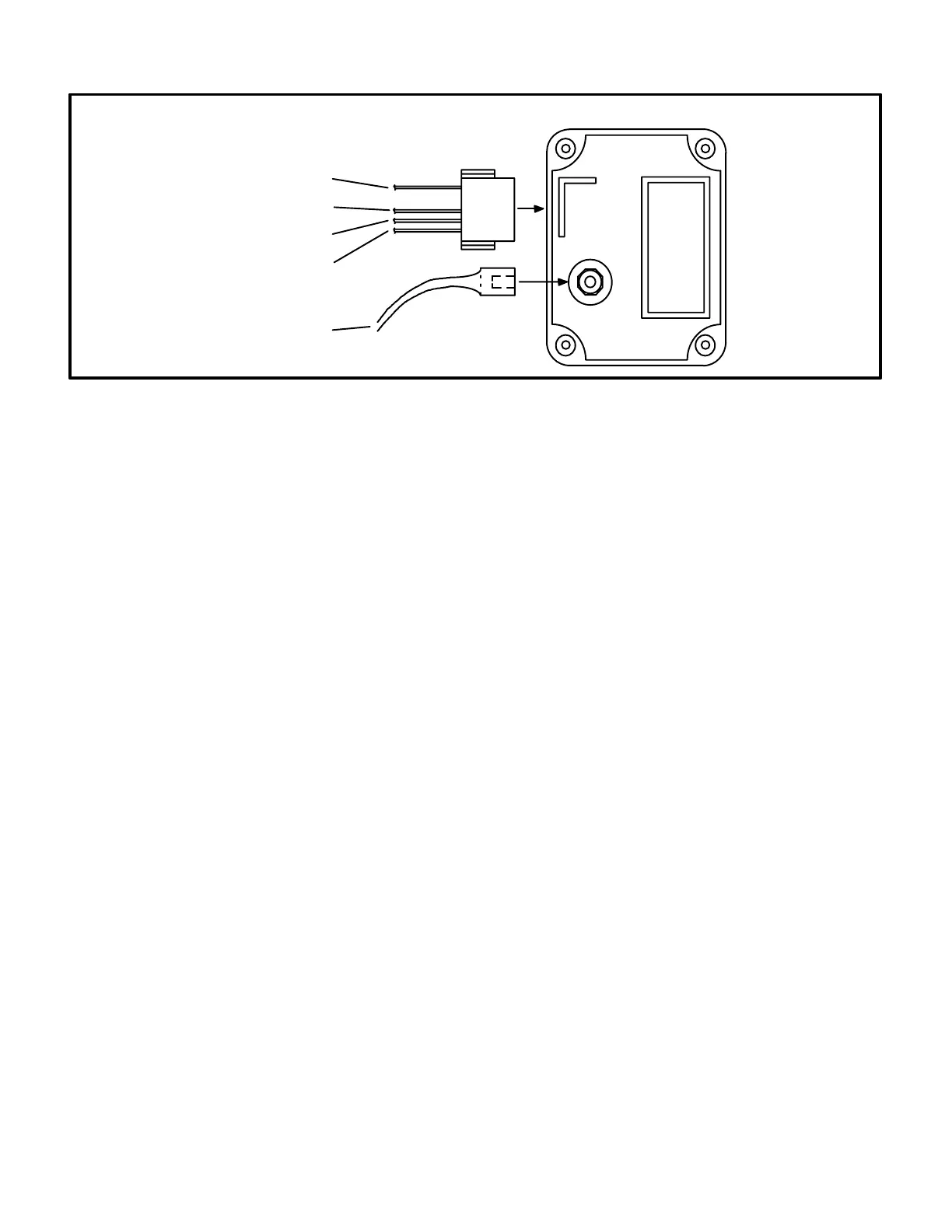

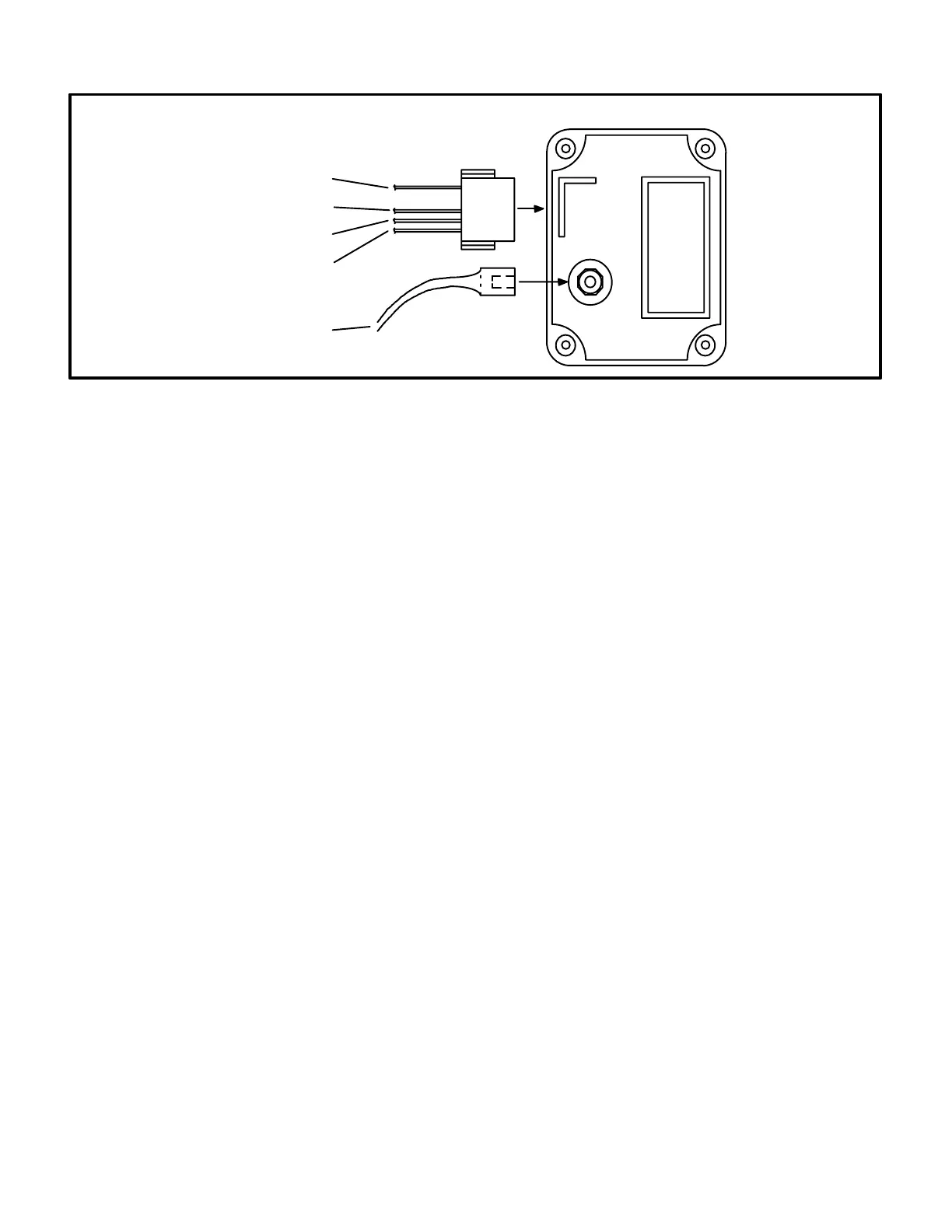

FIGURE 18

SPARK

HIGH VOLTAGE

POWER (24VAC INPUT)

TO GAS VALVE (24VAC OUTPUT)

TO FLAME SENSOR

GROUND

TOP VIEW

FENWAL IGNITION CONTROL

13-Electrode Assembly

The spark electrode/flame sensor assembly fits through a

hole in the burner plate. The electrode tips are located in

the path of the burner flame between the burner head and

the flame spreader. The electrode assembly is fastened to

the burner plate and can be removed for service without

removing any part of the burner assembly (except in units

with burner enclosure.)

During ignition spark travels through the spark electrode

and arcs across to the ground electrode. During operation,

flame is sensed by a current passed along the ground

electrode, through the flame and into the sensing elec

trode.

a-Spark Electrode

The spark electrode is connected to the ignition control

by a 5mm silicone insulated stranded high voltage

wire. The wire uses 1/4" female quick connect on the

electrode end and female spark plugtype terminal on

the ignition control end.

NOTE - IN ORDER TO MAXIMIZE SPARK ENER

GY TO THE ELECTRODE, THE HIGH VOLTAGE

WIRE SHOULD NOT REST ON THE BOTTOM

OF UNIT VESTIBULE PANEL AND SHOULD

TOUCH UNIT CABINET AS LITTLE AS POS

SIBLE.

b-Flame Sensor

Flame is sensed by rectification through the flame

sensing electrode.

14-Ignition Control A3

In GCS16H units, ignition control A3 is located in the unit

control box. In GCS16R and GCS16 units, ignition control

A3 is located in the heating compartment. On a heating

demand, the ignition control is energized after proving

combustion air blower operation. The control allows 30 to

40 seconds for the combustion air blower to vent exhaust

gases from the burner. The ignition control then activates

gas valve GV1, the spark electrode, the flame sensing

electrode and blower delay relay K25. The ignition control

is not adjustable.

WARNING - SHOCK HAZARD. SPARK RELATED

COMPONENTS CONTAIN HIGH VOLTAGE WHICH

CAN CAUSE PERSONAL INJURY OR DEATH. DIS

CONNECT POWER BEFORE SERVICING. CON

TROL IS NOT FIELD REPAIRABLE. UNSAFE OP

ERATION WILL RESULT. IF THE CONTROL IS IN

OPERABLE, SIMPLY REPLACE THE ENTIRE CON

TROL.

a- An electronic direct spark ignition with flame rectifi

cation sensing is used on all GCS16 units. Flame

signal strength ranges from 8 to 20 microamps.

All units have controls manufactured by Fenwal.

b- The Fenwal control is illustrated in figure 18. The

fourwire harness, plugged directly into a jack on

the side of the control, is used to connect the con

trol to the unit. Each of the four jack terminals is

identified by function. The spark electrode wire

connects to the spark plugtype connector on top

of the control.

c- The ignition control provides three main functions:

gas valve control, ignition and flame sensing. It is

powered only after the combustion air prove

switch has closed. The ignition attempt sequence

provides three trials for ignition before locking out.

The blower control (K25) is energized simulta

neously with the gas valve, so the blower will ener

gize 30 to 45 seconds after flame has successfully

been established. The unit will usually ignite on the

first attempt. See figure 19 for a normal ignition se

quence with nominal timings for simplicity.

Loading...

Loading...