Page 33

Burner is factory set and does not require adjustment.

End-cap (if used) cannot be adjusted. Always operate the

unit with access panel in place. A peep hole with cover is

furnished in the cabinet access panel for flame viewing.

On units equipped with burner enclosure, a glass viewing

port is also provided for viewing flame. The flame should

be blue with minimum yellow streaking.

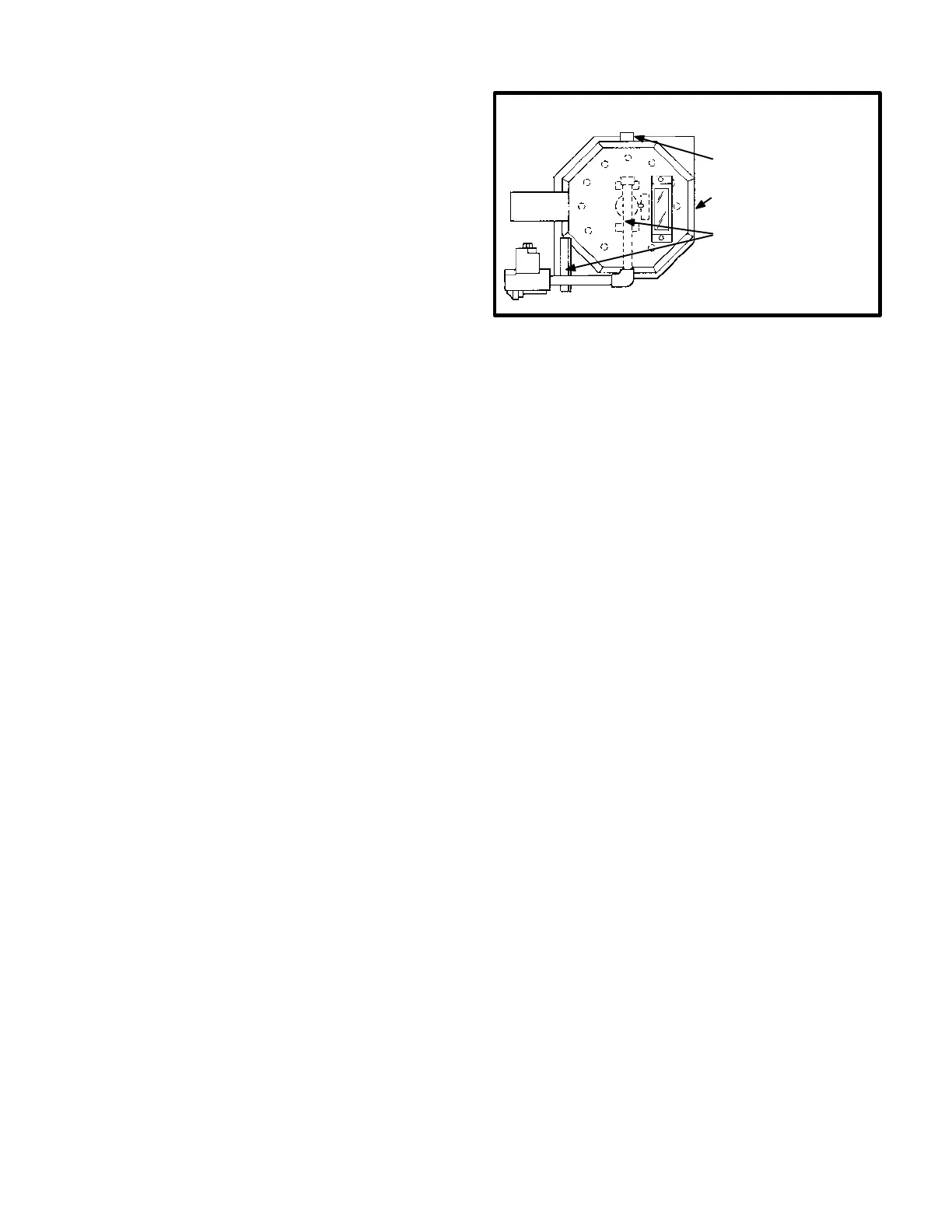

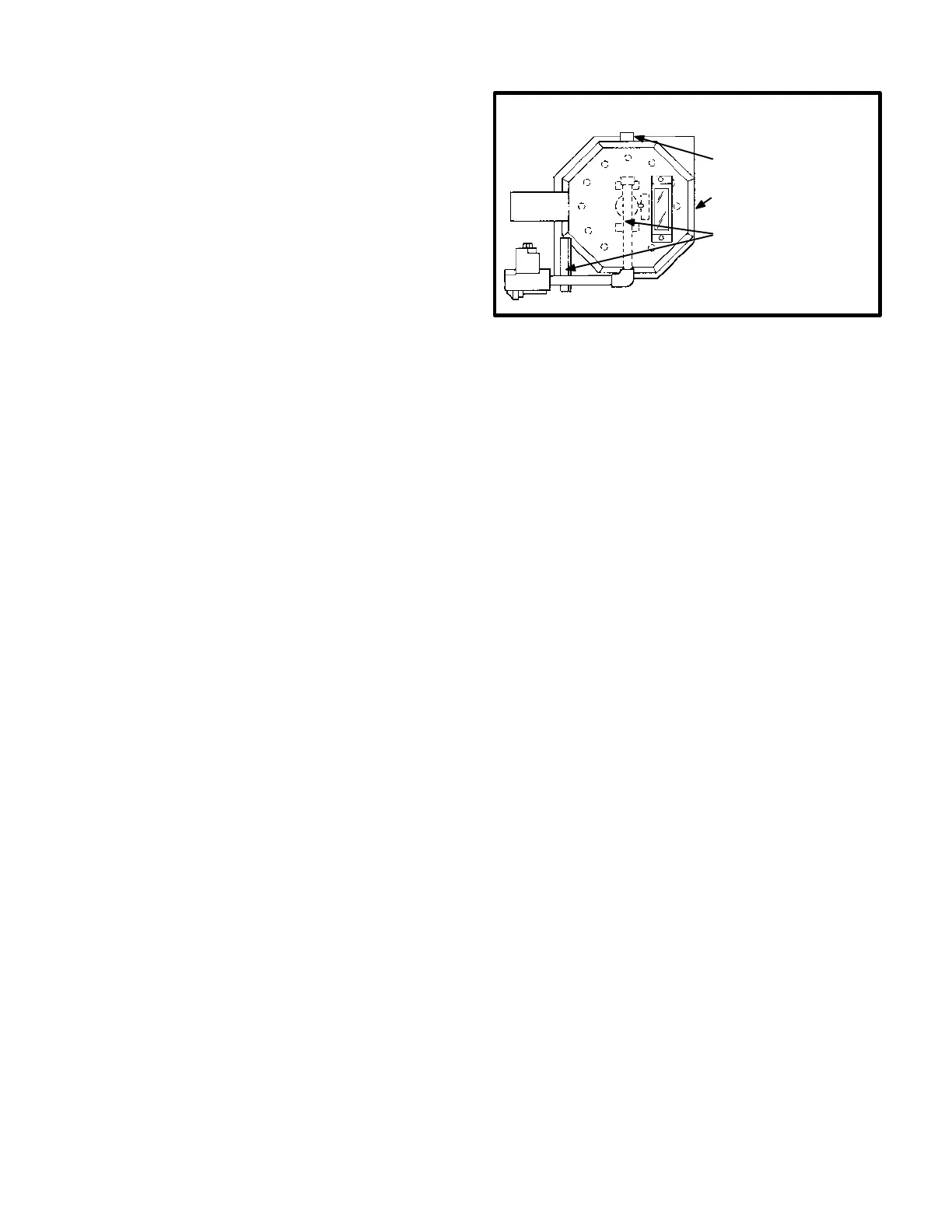

Figure 31 shows how to remove burner assembly.

1-Turn off power to unit and shut off gas supply.

2-Disconnect wires to rollout switch and gas valve.

3-Remove burner enclosure (if so equipped) by re

moving bolts securing enclosure to burner plate.

To remove the assembly, first remove octagon

backplate. Loosen nuts on top and bottom sur

faces at overlap and remove four mounting bolts

at burner plate.

4-Remove gas valve/manifold assembly by removing

bolts securing assembly to vestibule. Manifold,

valve and bracket will be removed as a unit.

NOTE - See figure 32 for CAUTION concerning

burner plate removal. First detach the gas man

ifold bracket. Next, remove the four screws secur

ing the gas burner manifold to the burner plate.

Take care not to damage ceramic cone in combus

tion chamber. If cone is damaged, it must be re

placed.

5-Slide burner off orifice.

6-Clean as necessary and reassemble (reverse

steps 1-5). Replace the four screws securing the

gas/burner manifold to the burner plate. (If burner

enclosure was previously removed, it must be

reassembled taking care not to create air leaks

due to misalignment of parts which will ad

versely affect unit performance.) Secure the

gas manifold bracket and ensure proper burner

head alignment. Bolts must be torqued to 35 in

lbs. to ensure proper operation.

7-Be sure to secure all wires and check plumbing and

burner plate for airtight seal.

8-Turn on power to unit. Follow lighting instructions

attached to unit and operate unit in heating mode.

Check burner flame. It should be blue with clear

yellow streaking.

FIGURE 31

GCS16 BURNER ASSEMBLY REMOVAL

1-Turn off power to unit.

2-Disconnect wires to rollout

switch and gas valve.

3-Remove burner enclosure

(if so equipped).

4-Remove valve/manifold

assembly.

5-Slide burner off orifice.

I-Burner Cone

When replacing the burner cone, the heat exchanger must

be removed. To remove or replace the burner cone refer

to the procedure for removing the heat exchanger in sec

tion K-Heat Exchanger."

CAUTION - AFTER UNIT HAS BEEN OPERATED,

BURNER CONE CAN BE EASILY DAMAGED BY

HANDLING. IT MUST BE HANDLED CAREFULLY.

CONE MUST BE REPLACED IF EITHER INSIDE OR

OUTSIDE EDGE ARE DAMAGED. A DAMAGED IN

SIDE EDGE CAN CAUSE IMPROPER OPERATION.

A DAMAGED OUTSIDE EDGE CAN CAUSE EX

HAUST PRODUCTS TO ENTER LIVING SPACE.

DO NOT ALLOW UNIT TO OPERATE WITH A DAM

AGED BURNER CONE.

J-Burner Plate Gasket

The burner plate gasket needs to be inspected or replaced

only when the burner plate or heat exchanger are re

moved. When replacing the burner plate gasket, the burn

er, gas valve and manifold assembly must be removed.

To Replace Burner Plate Gasket:

1-Turn off power to unit and shut off gas supply.

2-Disconnect rollout switch and gas valve wires.

3-Remove burner enclosure (if so equipped) by re

moving bolts securing enclosure to burner plate.

4-Remove gas valve/manifold assembly by removing

bolts securing assembly to vesibule.

5-Remove burner plate by removing bolts securing

burner plate to vestibule.

NOTE - See figure 32 regarding slots in burner plate.

Loading...

Loading...