Page 59

a-The COOL MODE" LED lights green to indicate

economizer free cooling" operation when unit in

cludes the economizer option. Otherwise, the LED

indicates mechanical cooling operation.

b-The HEAT MODE" LED lights green during normal

heating operation.

c-The COMPRESSOR 1" LED lights green when the

compressor is running. The light turns red if a com

pressor safety switch opens during a compressor

demand (singlephase units must be equipped with

optional Controls Package for the red function of

this LED to operate).

d-The COMPRESSOR 2" LED is not used in GCS16

210 through 650 series units.

e-The NO HEAT" LED lights red on a loss of heat dur

ing a heating demand.

f- The FILTER" LED lights red when optional filter

pressure switch contacts close indicating a dirty fil

ter.

g-The SYSTEM" switch on the SSP11 has five posi

tions to indicate the following functions:

OFF" - System off.

HEAT" - System operates in heating mode only.

AUTO" - System automatically provides heating or

cooling on demand.

COOL" - System operates in cooling mode only.

EM HEAT" - (Emergency Heat) Not used in

GCS16 units, but if placed in this position, the unit

operates in the normal heating only mode.

h-The FAN" switch on the SSP11 has two positions to

indicate the following functions:

AUTO" - Blower cycles with demand.

ON" - Blower runs continuously.

i- The AFTER HOURS TIMER" on the SSP11 pro

vides override of unoccupied mode operation (night

heating setback / cooling setup) from 0 to 12 hours.

In the occupied (day) mode, the after hours timer

has no effect on unit operation.

The unit must be in the unoccupied mode (night) to

activate the timer. Set the potentiometer for the

number of hours desired override and push the mo

mentary start button. The unit reverts to occupied

mode operation for the set number of hours.

4-Installation and Wiring

The SP11 and SSP11 require relay kits to interface the

status panel to the control system and the unit. The fol

lowing sections list the operation sequence and instal

lation procedures for the relay kits and the status pan

els.

a-Readout Relay Kit

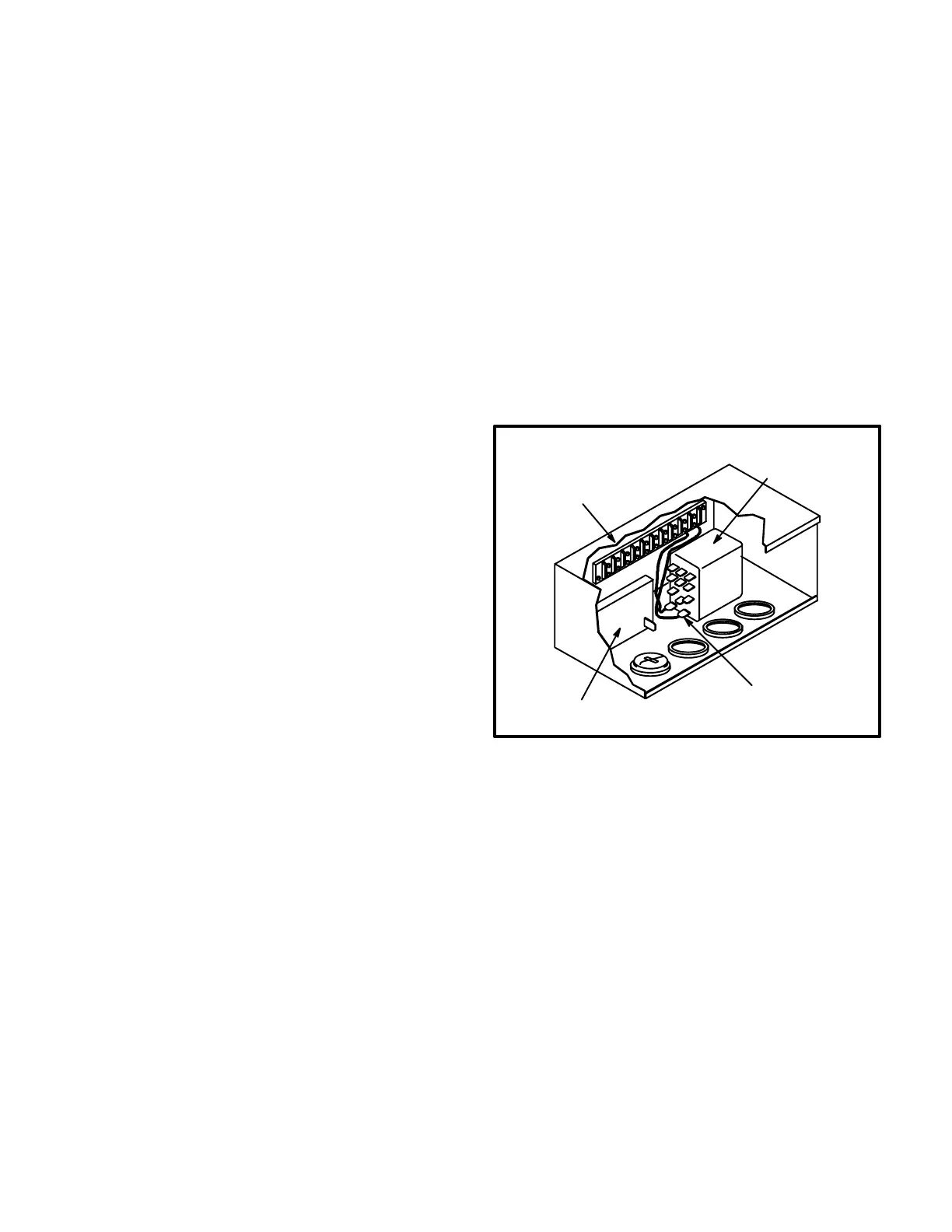

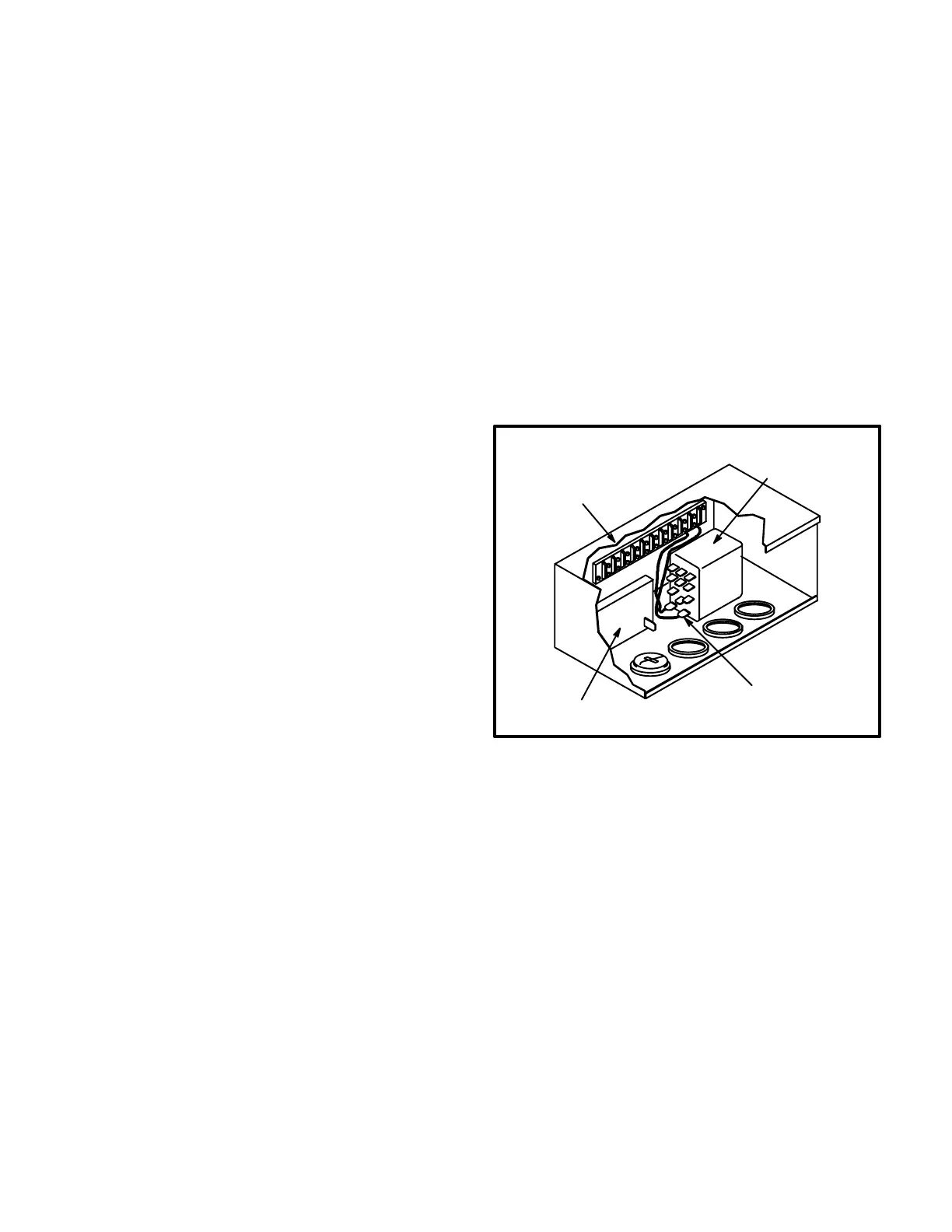

A readout relay kit (readout relay box - RRB) is re

quired for all units using either the SP11 or SSP11

status panels. RRB is shown in figure 78. The RRB

includes relays which interface the status panels to

the unit. The status panels will not operate without

the RRB.

FIGURE 78

READOUT RELAY BOX

RELAY K29

TERMINAL STRIP

TIME DELAY DL6

CONNECT RELAY COIL TERMI

NALS C AND C TO TERMINAL

STRIP TERMINALS 9 AND 10.

RRB Sequence of Operation:

1- Initial heating demand (W1) from the unit is

routed through RRB terminal 2 to SP11 terminal

2 to light the green HEAT" light.

2- The same heat demand is routed through RRB

terminal 2 and through (RRB relay) K29 N.C.

contacts to energize time delay DL6.

3- Time delay DL6 begins a 60second count before

closing.

Loading...

Loading...