Page 28

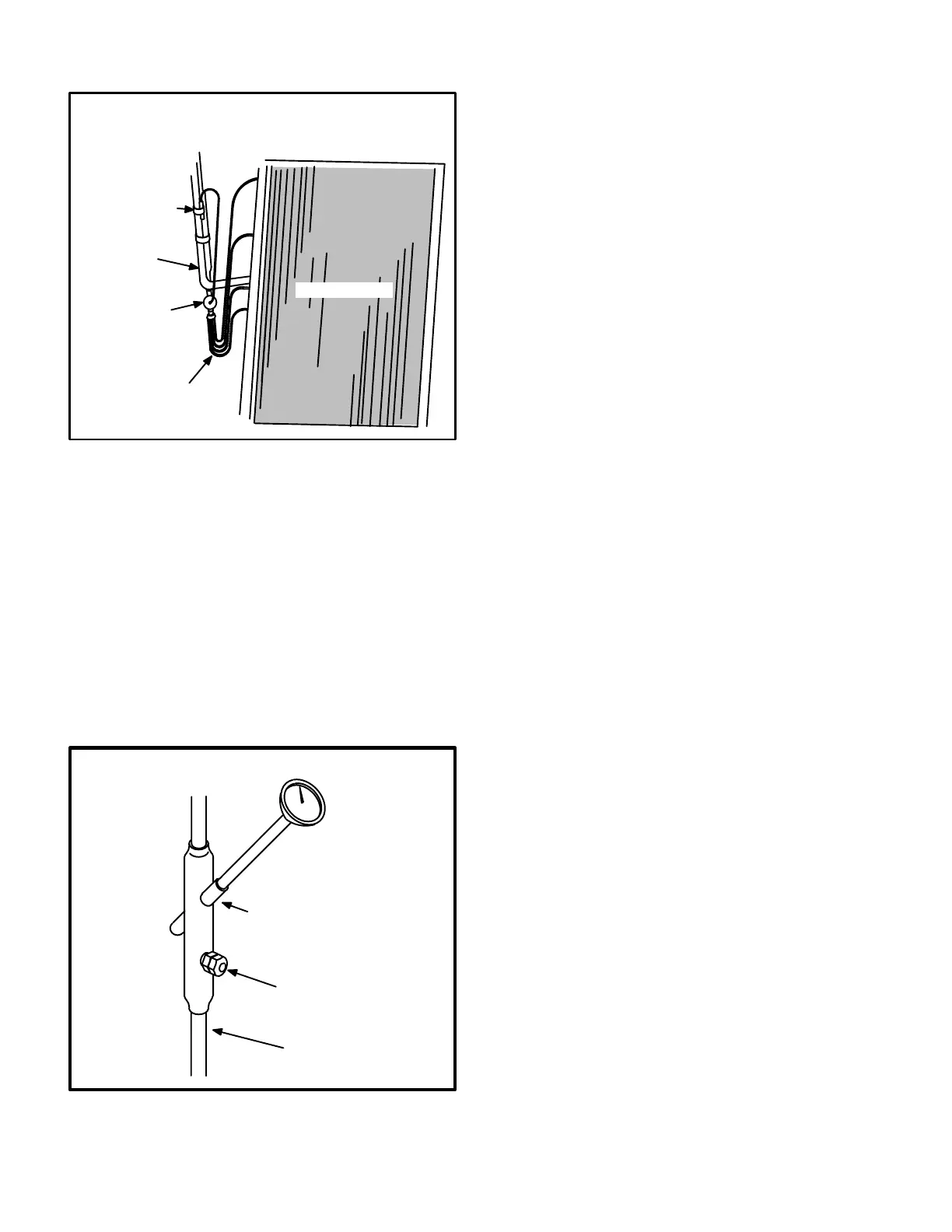

FIGURE 27

EVAPORATOR PLUMBING

GCS16-511/513, GCS16-651/653

GCS16R-511 and GCS16R-651

EVAPORATOR

EXPANSION

VALVE FED BY

LIQUID LINE

SUCTION

LINE

SENSING

BULB STRAPPED

TO SUCTION LINE

FEEDER TUBES

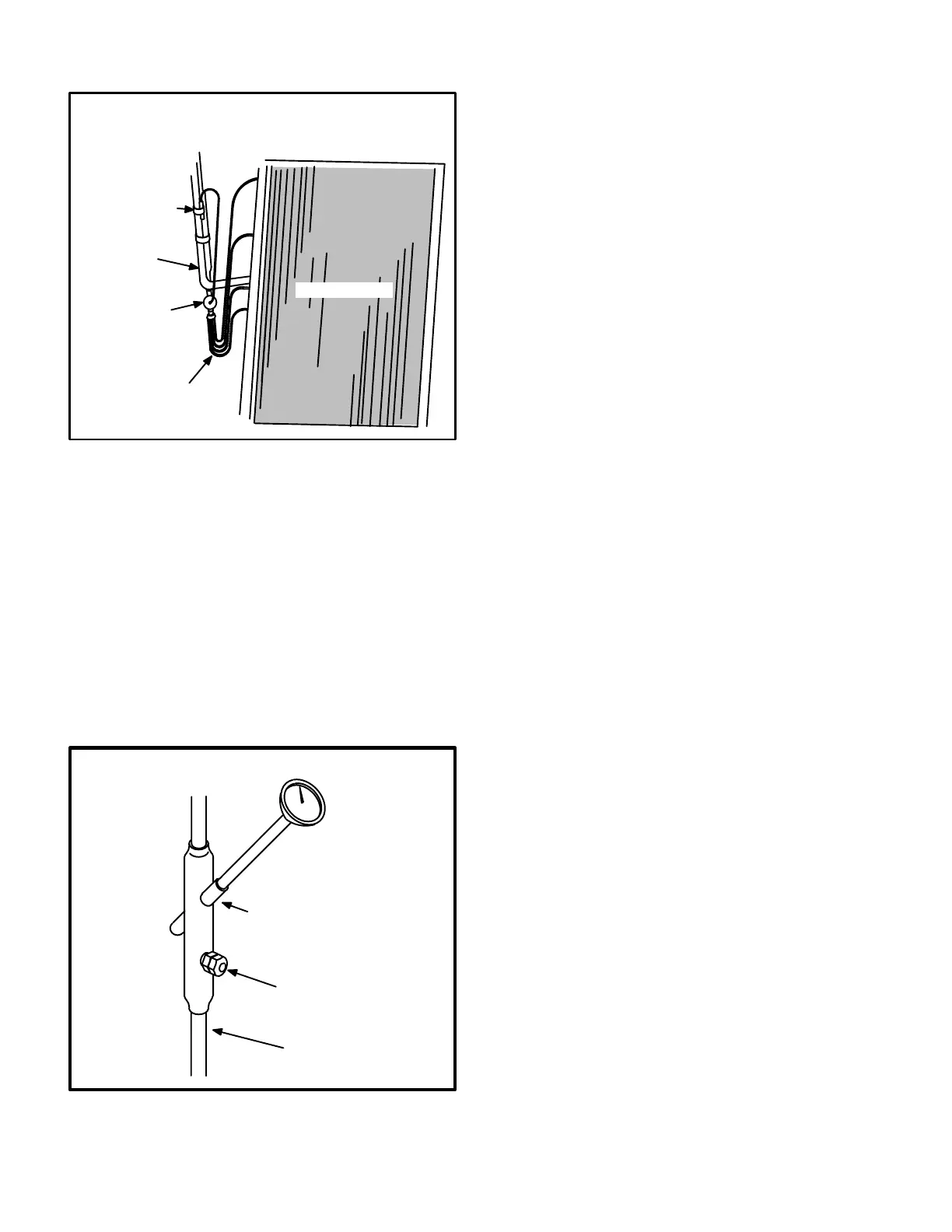

12-Thermometer Well (Figure 28)

All units are factory equipped with a thermometer well for

charging the unit. The well is used to accurately measure

the temperature of the liquid line. The temperature mea

sured is then used to calculate the approach or subcooling

temperature. Approach and subcooling temperatures are

compared to tables printed in the charging section of this

manual to determine the correct charge. The thermome

ter wells are equipped with a gauge port for connection of

high pressure gauge.

To accurately measure the temperature of the liquid line,

the well should be filled with a light mineral oil before using.

This will ensure good heat transfer to the thermometer.

FIGURE 28

THERMOMETER WELL

THERMOMETER WELL

LIQUID LINE

GAUGE PORT

LIQUID LINE

III-PLACEMENT AND INSTALLATION

Make sure that the unit is installed in accordance with the

installation instructions and all applicable codes. See ac

cessories section for conditions requiring use of the op

tional roof mounting frame (RMF16).

IV-ELECTRICAL CONNECTIONS

A-Power Supply

Refer to startup directions and refer closely to the unit wir

ing diagram when servicing. Refer to unit nameplate for

minimum circuit ampacity and maximum fuse size.

208/460/575 volt units are factory wired with red wire con

nected to control transformer primary. 230 volt units are

field wired with orange wire connected to control trans

former primary.

DANGER - ALL SINGLEPHASE UNITS USE

SINGLEPOLE CONTACTORS. COMPRESSOR

(TERMINAL R), ONE LEG OF THE START AND

RUN CAPACITORS AND ONE LEG OF THE CON

DENSER FAN ARE POWERED AT ALL TIMES.

MAKE SURE POWER IS TURNED OFF AT DISCON

NECT BEFORE SERVICING UNIT.

V-STARTUP - OPERATION

A-Preliminary Checks

1- Make sure that the unit is installed in accordance with

the installation instructions and applicable codes.

2- Inspect all electrical wiring, both field and factory

installed for loose connections. Tighten as required.

3- Check to ensure that refrigerant lines are in good con

dition and do not rub against the cabinet or other re

frigerant lines.

4- Check voltage at the disconnect switch. Voltage must

be within the range listed on the nameplate. If not,

consult the power company and have the voltage con

dition corrected before starting the unit.

5- Recheck voltage with unit running. If power is not with

in range listed on unit nameplate, stop unit and consult

power company. Check amperage of unit. Refer to

unit nameplate for correct running amps.

Loading...

Loading...