Do you have a question about the Lennox GCS16-953 and is the answer not in the manual?

Introduces GCS16 series as packaged two-stage gas/dx cool units for commercial applications.

Details ARI ratings, refrigerant charge, and blower/drive specifications for GCS16 units.

Details two-stage heating capacity for natural and LPG gas, plus gas supply connections.

Details specifications for GCS16-1853 series, including cooling capacity and heating input.

Provides specifications for GCS16-2553 series, including cooling capacity and heating input.

Lists specifications for GCS16-2753 series, including cooling capacity and heating input.

Details specifications for GCS16-3003 series, including cooling capacity and heating input.

Lists optional LPG conversion kits and roof mounting frames for specific GCS16 models.

Details optional economizer and exhaust dampers, including filter sizes and face area.

Lists optional LPG conversion kits and roof mounting frames for GCS16-1353 to GCS16-3003.

Details optional economizer and exhaust dampers for larger GCS16 units.

Provides electrical data for compressors and condenser fan motors, including amps and horsepower.

Details electrical data for the evaporator blower motor and minimum circuit ampacity.

Presents blower performance data (RPM, BHP) at various air volumes and static pressures.

Provides blower performance data for GCS16-1353 at different air volumes and static pressures.

Details blower performance for GCS16-1853-235, including RPM and BHP at various conditions.

Explains how to adjust blower speed and general maintenance for the blower compartment.

Presents blower performance data for larger GCS16 models at various air volumes and static pressures.

Details blower performance for GCS16-2553 and GCS16-2753 units.

Lists specifications for blower motors, including HP, Usage, Volts, and Phase.

Provides blower performance data for higher tonnage GCS16 units.

Covers blower motor maintenance, including cleaning and lubrication requirements.

Details blower performance for GCS16-3003 models at various operating conditions.

Lists total resistance values for various economizer and diffuser accessories.

Provides air throw data for different ceiling diffuser types and air volumes.

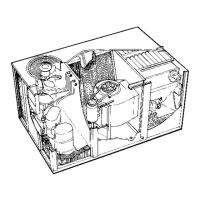

Shows a diagram of the parts arrangement for GCS16-823/953 units.

Illustrates the parts arrangement for GCS16-1853 units, highlighting key components.

Identifies and illustrates the components within the control box for GCS16-823 and GCS16-953.

Details the components found within the control box of the GCS16-1853 unit.

Explains the function and location of the power distribution terminal block (TB13).

Describes the low voltage terminal strip (TB1) for thermostat and control wiring connections.

Details terminal block TB17 and transformer T1, used for low voltage and control power.

Explains the function of transformers T18, T3, and fuses F10, F16 in the control system.

Describes the function of condenser fan contactors K10 and K68 in controlling fan operation.

Details the combustion air blower relay K13 and pilot relay board A11 functions.

Explains the function of low ambient lockout switch S30 and compressor delay DL15.

Explains the function of low ambient lockout switch S30 and compressor delay DL15.

Illustrates typical heat exchanger assemblies, showing single and dual configurations.

Shows heating control components for units with a single heat exchanger.

Illustrates heating control components for units equipped with dual heat exchangers.

Explains the roles of K13 (combustion air blower) and K20 (indoor blower limit) relays.

Details the function of K19 (2nd stage heat) and K56/K57 (heat blower) relays.

Details the ignition control A3 function and essential safety warnings.

Explains the importance of proper spark electrode and flame sensor gap for ignition.

Provides instructions for burner removal and electrode/sensor orientation.

Explains the timing sequences for the Fenwal ignition control, including retrials and lockout.

Details the function of heat exchangers and how the gas valve stages heating operation.

Describes the burner assembly, orifices, and their function in gas flow.

Explains the function of primary (S10) and secondary (S21) high temperature limit switches.

Details the function of flame rollout switches S47 and S69 for safety during heating.

Explains the combustion air blower operation and the role of prove switches S18 and S45.

Details gas valve operation, regulation, and factory settings for GCS16 units.

Describes the electrode assembly used for ignition spark and flame sensing.

Explains the function of the spark electrode and flame sensor in the ignition process.

Shows a diagram of the plumbing components for GCS16-823 and GCS16-953 units.

Illustrates the plumbing components in the condensing section for GCS16-1853 units.

Shows plumbing components for the condensing section of GCS16-2553, -2753, -3003.

Illustrates the evaporator section plumbing for GCS16-1853 units.

Discusses compressor operation, crankcase heaters, and essential safety warnings.

Details the function of high pressure limit switches in protecting compressors.

Explains loss of charge switches and the use of thermometer wells for charging.

Details the indoor blower motor specifications and components within the blower compartment.

Provides guidance on unit placement, installation, and ensuring compliance with codes.

Outlines cooling startup procedures, including essential warnings about compressor heaters.

Details cooling system checks, focusing on the approach method for refrigerant charge.

Explains how to attach gauge manifolds and perform refrigerant charging.

Describes gas piping components and safety precautions for installation and testing.

Details procedures for testing gas supply and manifold pressures.

Explains how to check gas flow and adjust for high altitude derating.

Describes the inshot burner and how to view the flame for proper operation.

Details the ignition control A3 function and essential safety warnings.

Explains the correct gap for spark electrodes and the flame sensing process.

Explains how to measure unit CFM using static pressure and blower RPM.

Details the procedure for adjusting the blower belt tension and alignment.

Provides instructions for cleaning evaporator and condenser coils for optimal performance.

Covers electrical checks, including wiring and motor ratings verification.

Covers electrical checks, including wiring and motor ratings verification.

Details the installation procedure for the OAD16 outdoor air damper section.

Details the installation procedure for the OAD16 outdoor air damper section.

Describes economizer components like dampers, sensors, and optional accessories.

Explains the operation and control of the REMD16M economizer.

Explains the operation and control of the REMD16M economizer.

Provides performance data for the PED16 power exhaust damper.

Provides performance data for the PED16 power exhaust damper.

Details optional GED16 gravity exhaust dampers for economizer systems.

Describes the warm-up kit for economizers, including installation and function.

Describes the warm-up kit for economizers, including installation and function.

Explains the setpoint control function of the economizer's enthalpy control.

Details the function of the enthalpy and mixed air sensors in economizer operation.

Details the function of the enthalpy and mixed air sensors in economizer operation.

Outlines the procedure for checking the modulating damper motor on REMD16M economizers.

Outlines the procedure for checking the modulating damper motor on REMD16M economizers.

Describes optional transitions and supply/return diffusers for economizer systems.

Describes optional transitions and supply/return diffusers for economizer systems.

Explains the requirements for installing firestats according to local codes.

Details the function of the cycle control kit, including delays for compressor and blower operation.

Explains how compressor monitors interact with low ambient kits and wiring considerations.

Explains how compressor monitors interact with low ambient kits and wiring considerations.

Introduces status panels SP11 and SSP11 for monitoring system operation.

Describes the application and functions of the SSP11 switching status panel.

Describes the application and functions of the SSP11 switching status panel.

Explains the indicators and control functions of the SSP11 panel.

Details the function of Jack J2/P2 and J3/P3 for heating and economizer connections.

Details the function of Jack J2/P2 and J3/P3 for heating and economizer connections.

Explains the use of J16/P16 for control systems and J18/P18 for power exhaust dampers.

Describes the J57 connection for the optional "dirty filter" indicator switch.

Describes the J57 connection for the optional "dirty filter" indicator switch.

Lists optional commercial control systems and their associated wiring diagrams.

Shows the relay kit installation for warm-up kits on smaller GCS16 units.

Shows the relay kit installation for warm-up kits on smaller GCS16 units.

Illustrates the relay kit installation for warm-up kits on larger GCS16 units.

Details the C2-1 wiring diagram for systems with economizers and warm-up kits.

Details the C2-1 wiring diagram for systems with economizers and warm-up kits.

Explains the C11-1 wiring diagram and how it facilitates night setback.

Details the C5 and C6 wiring diagrams for Prostat control systems.

Details the C5 and C6 wiring diagrams for Prostat control systems.

Describes the C7-3 wiring diagram for the Honeywell W7400 control system.

Explains the C12 wiring diagrams for T7300 electronic thermostats.

Explains the C12 wiring diagrams for T7300 electronic thermostats.

Details the CMC3-1 time clock and its wiring connections for setback operation.

Describes the step-by-step operation sequence for GCS16-823/953 with an electromechanical thermostat.

Details the sequence of operations for cooling demand in GCS16-823/953 units.

Details the sequence of operations for cooling demand in GCS16-823/953 units.

Outlines the sequence of operations for heating demand in GCS16-823/953 units.

Describes the operation sequence for GCS16-1353 units with an electromechanical thermostat.

Details the sequence of operations for cooling demand in GCS16-1353 units.

Details the sequence of operations for cooling demand in GCS16-1353 units.

Outlines the sequence of operations for heating demand in GCS16-1353 units.

Describes the operation sequence for GCS16-1603 units with an electromechanical thermostat.

Details the sequence of operations for cooling demand in GCS16-1603 units.

Details the sequence of operations for cooling demand in GCS16-1603 units.

Outlines the sequence of operations for heating demand in GCS16-1603 units.

Describes the operation sequence for GCS16-1853 units with an electromechanical thermostat.

Details the sequence of operations for heating demand in GCS16-1853 units.

Details the sequence of operations for heating demand in GCS16-1853 units.

Describes the operation sequence for GCS16-2553/2753/3003 units with electromechanical thermostat.

Details the heating demand sequence for higher BTUH GCS16 models.

Details the heating demand sequence for higher BTUH GCS16 models.

Describes the operation sequence for GCS16-2553/2753/3003 units with electromechanical thermostat.

Details the heating demand sequence for higher BTUH GCS16 models.

Details the heating demand sequence for higher BTUH GCS16 models.

Shows wiring connections for economizer components like enthalpy control and damper motors.

Shows wiring connections for economizer components like enthalpy control and damper motors.

Explains economizer operation during low and high enthalpy conditions for cooling.

Explains economizer operation during low and high enthalpy conditions for cooling.

Details night setback operation and the function of the warm-up kit with economizers.

Shows wiring connections for economizer and warm-up kits with thermostats.

Shows wiring connections for economizer and warm-up kits with thermostats.

Explains how the warm-up kit functions during night setback and morning warm-up.

Explains how the warm-up kit functions during night setback and morning warm-up.

| Brand | Lennox |

|---|---|

| Model | GCS16-953 |

| Category | Gas Heater |

| Language | English |

Loading...

Loading...