Page 38

D-Blower Speed Adjustment

460V and 575V Units ONLY

All 460V and 575V units have three speed blower motors

with pigtail leads (taps). The taps are arranged as shown

in table 20. Both 460V and 575V units use 460V blower

motors. 575V units use a stepdown transformer in the

unit control box to provide 460V to the motor.

TABLE 20

FOUR SPEED BLOWER MOTORS

Speed Tap Color

Low

Medium

High

Internal Circuit

Common

Red

Yellow

Black

Blue

Orange

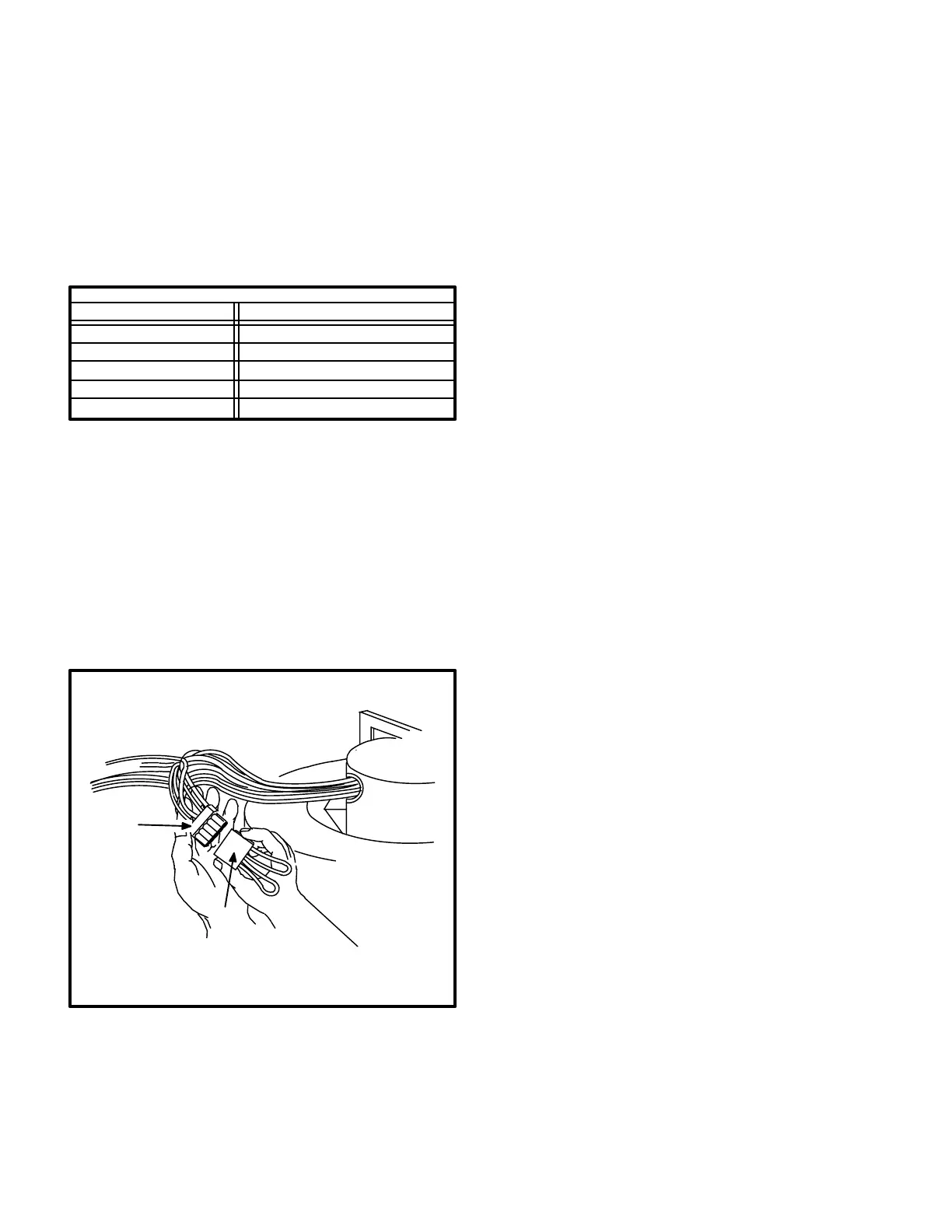

The motor is equipped with speed leads (taps) for chang

ing motor speed. The taps are connected to harness plug

P38 along with line voltage wires from blower relay. Jump

er J38 is used to complete the circuit to the blower motor

and provide the proper heating and cooling speed. J38 is

also used to provide the necessary blue leg" circuit which

460V motors require (refer to figure 24 for more informa

tion). Blower speed selection is accomplished by chang

ing the harness jumpers in the harness connector at the

blower motor (see figure 38).

FIGURE 38

BLOWER SPEED TAP SELEC

TION

460V and 575V UNITS

P38

J38

Three J38 jumpers are provided with the unit. Each is marked

with different speeds. To change blower speeds, disconnect the

installed J38 jumper and install one of the other J38 jumpers.

BLOWER

BLOWER

MOTOR

Three J38 jumpers are provided with the unit. Each pro

vides the speeds marked on the jack (HiCool / LoHeat,

MedCool / MedHeat or HiCool / MedHeat) and the

blue leg" circuit referred to in figure 24.

Use the steps outlined in the previous section (Blower

Speed Adjustment 208V/230V Only) to determine which

J38 jumper to use.

WARNING - DO NOT ISOLATE MEDIUM OR LOW

SPEED WINDINGS WHEN OPERATING AT ME

DIUM OR LOW SPEED. THE BLUE LEAD MUST

NEVER BE CONNECTED TO A POWER LEAD

(BLOWER DEMAND FROM HEAT RELAY OR

BLOWER RELAY) OR TO COMMON. FAILURE TO

CONNECT THE BLUE TAP AS SHOWN ON THE

UNIT DIAGRAM WILL CAUSE IMPROPER OPERA

TION, INCREASED CURRENT FLOW AND/OR

BURNT WINDINGS.

IX-MAINTENANCE

CAUTION - TURN OFF GAS AND ELECTRICAL

POWER TO THE UNIT BEFORE PERFORMING

ANY MAINTENANCE OR SERVICE OPERATION

ON THE UNIT. REMEMBER TO FOLLOW LIGHT

ING INSTRUCTIONS ATTACHED TO THE UNIT

WHEN PUTTING THE UNIT BACK INTO OPERA

TION.

BE CAREFUL WHEN SERVICING UNIT TO AVOID

ACCIDENTAL CONTACT WITH SHARP METALLIC

EDGES WHICH MAY CAUSE INJURY.

A-Lubrication

NOTE - Always relubricate motors according to

manufacturer's lubrication instructions provided on

each motor. If no instructions are provided, use the fol

lowing as a guide:

1- Supply Air Motor Bearings - Bearings are prelubri

cated; no further lubrication is required for 10

years of normal operation. Thereafter, oil at oiling

ports or clean and repack bearings with a suitable

bearing grease every two years, whichever is ap

plicable.

2- Combustion Air Blower Motor Bearings - Bearings

are prelubricated. For extended bearing life, lubri

cate each bearing through the oiling ports pro

vided. Use a few drops of a good grade of electric

motor oil or SAE10 or SAE20 nondetergent motor

oil every two years.

3- Condenser Fan Motor Bearings - Bearings are

prelubricated. For extended bearing life, lubricate

each bearing through the oiling ports provided with

a few drops of a good grade electric motor oil or

SAE10 or SAE20 nondetergent motor oil every

two years.

Loading...

Loading...