Page 52

F-LPG Kit

All A.G.A rated GCS16s are factory set for use with Natu

ral Gas. An optional L.P.G. conversion kit allows change

over from Natural to L.P.G. supply. The kit includes a gas

valve changeover kit, new gas orifice and either combus

tion air orifice or combustion air restrictor plate.

All C.G.A. rated GCS16s are factory set for use with Natu

ral or L.P. gases. Each unit must be ordered for the type of

gas to be used. Field changeover is not allowed.

Refer to the L.P.G. Conversion Kit Installation Instruction

for specific installation procedures.

WARNING - IMPROPER INSTALLATION, ADJUST

MENT, ALTERATION, SERVICE OR MAINTE

NANCE CAN CAUSE INJURY, PROPERTY DAM

AGE OR DEATH. CONSULT A QUALIFIED IN

STALLER, SERVICE AGENCY OR THE GAS SUP

PLIER FOR INFORMATION OR ASSISTANCE.

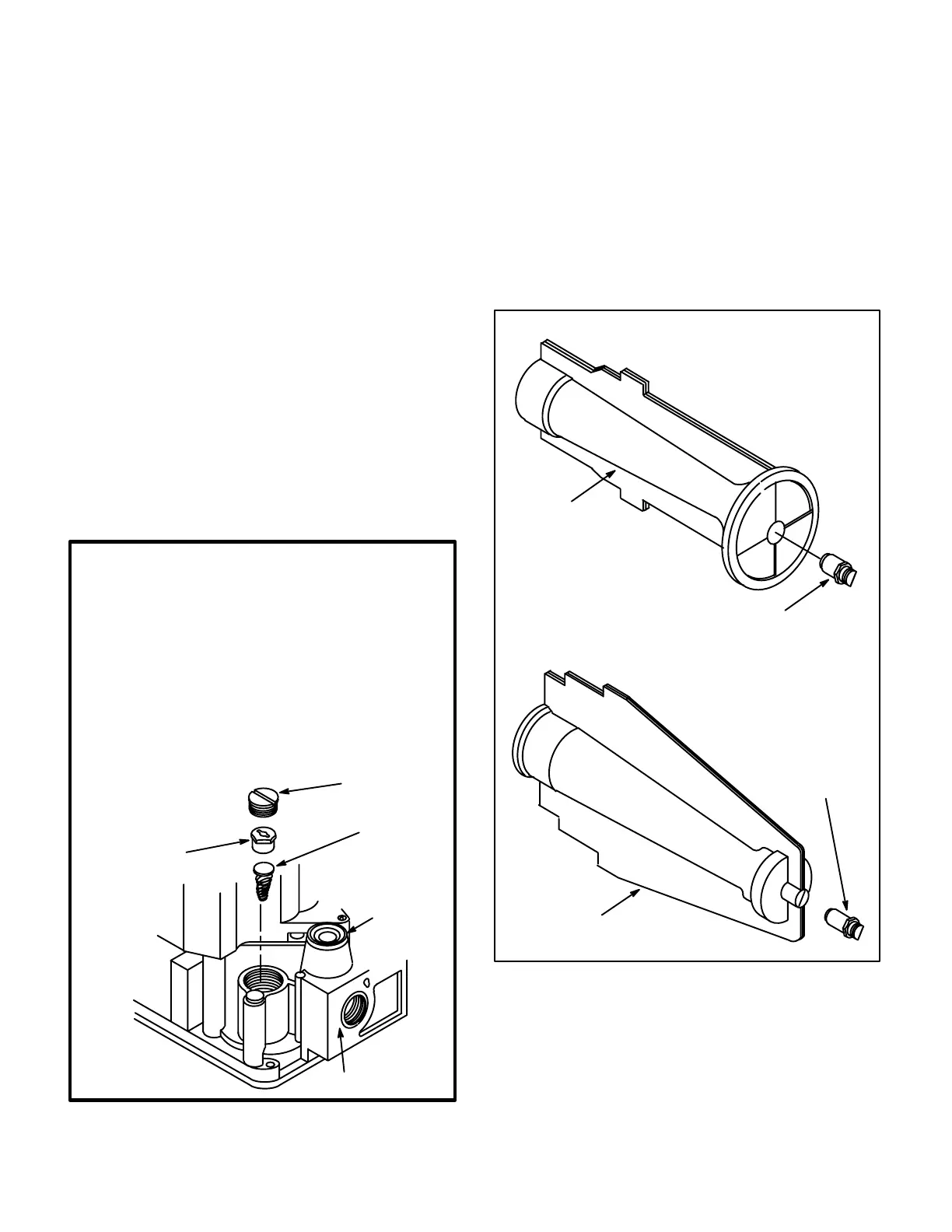

FIGURE 60

INLET

PRESSURE

TAP

1. Remove regulator cap screw and pressure regulator adjusting

screw.

2. Remove existing spring.

3. Insert replacement spring with tapered end down.

4. Install the new plastic pressure regulator adjustment screw so

that the top of the screw is flush (level) with the top of the regula

tor. Turn the pressure regulator adjusting screw clockwise six

complete turns, This adjustment provides a preliminary pressure

setting of about 10" w.c. (2.5 kPa) for the LP regulator.

5. Check regulator setting either with a manometer or by clocking

the gas meter.

6. Install new cap screw.

CONVERSION OF HONEYWELL GAS

VALVE (Natural to LP)

CAPSCREW

(Black)

PRESSURE

REGULATOR

ADJUSTING

SCREW (White)

SPRING

Tapered End

Down (Red)

GAS INLET

All units which have been changed to L.P.G. operation

should be marked with a yellow sticker located near the

gas valve. Some of the components you may find in a unit

which has been converted to L.P.G. operation are listed

below. Do not use this information as an installation proce

dure.

L.P.G. conversion in all GCS16 units requires that the gas

valve be field converted and the burner orifice be changed.

Figure 60 shows gas valve conversion. Figure 61 shows

the orifice changeout.

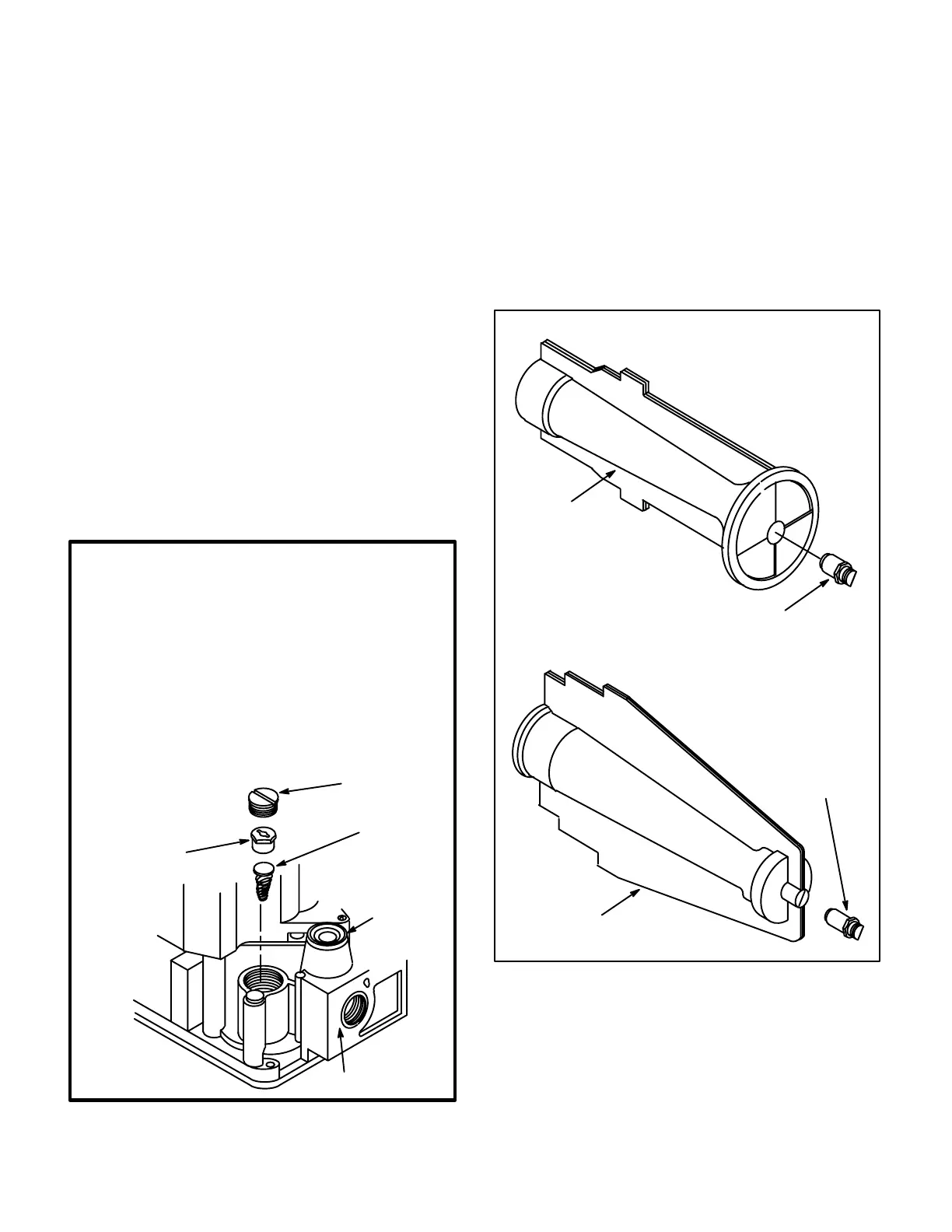

FIGURE 61

INSTALLING LPG GAS ORIFICE

BURNER

ASSEMBLY

GAS ORIFICE

BURNER SLIDES ONTO ORIFICE.

ORIFICE IS THREADED INTO MANIFOLD.

BURNER

ASSEMBLY

GAS ORIFICE

100K and125K Btuh BURNER

50K and 75K Btuh BURNER

L.P.G. conversion of 50K Btuh heat exchangers requires a

new combustion air orifice. In GCS16H-50 units, the ori

fice is located between the combustion air blower and the

flue transition as shown in figure 62. In GCS16-50 and

GCS16R-50 units, the orifice is located outside the cabi

net between the outer mullion and the flue vent as shown

in figure 63.

Loading...

Loading...