Page 35

diately in the event of a gas or power failure. Upon restora

tion of gas and power, the control will restart the ignition

sequence and continue until flame is established or sys

tem lockout occurs.

For proper unit operation, the electrodes must be positioned

correctly in the flame and must be gapped correctly.

DANGER - SHOCK HAZARD. SPARK RELATED

COMPONENTS CONTAIN HIGH VOLTAGE. DIS

CONNECT POWER BEFORE SERVICING.

WARNING - THE IGNITION CONTROL IS NOT

FIELD REPAIRABLE. UNSAFE OPERATION WILL

RESULT.

M-Spark Electrode/Flame Sensor/Spark

Gap

DANGER - SHOCK HAZARD. SPARK RELATED

COMPONENTS CONTAIN HIGH VOLTAGE. DIS

CONNECT POWER BEFORE SERVICING.

The electrode assembly can be removed for inspection by

removing two screws securing the electrode assembly

and sliding it out of unit.

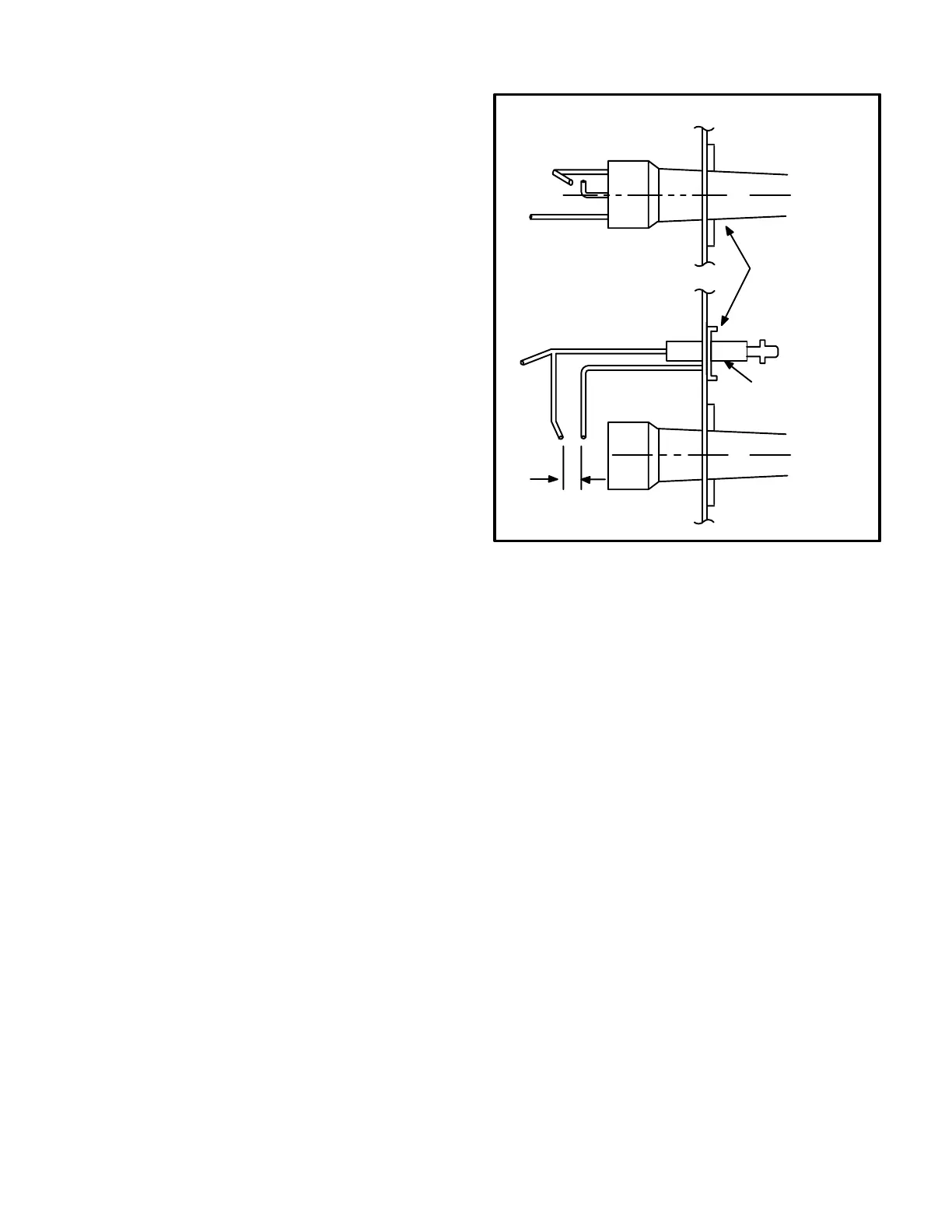

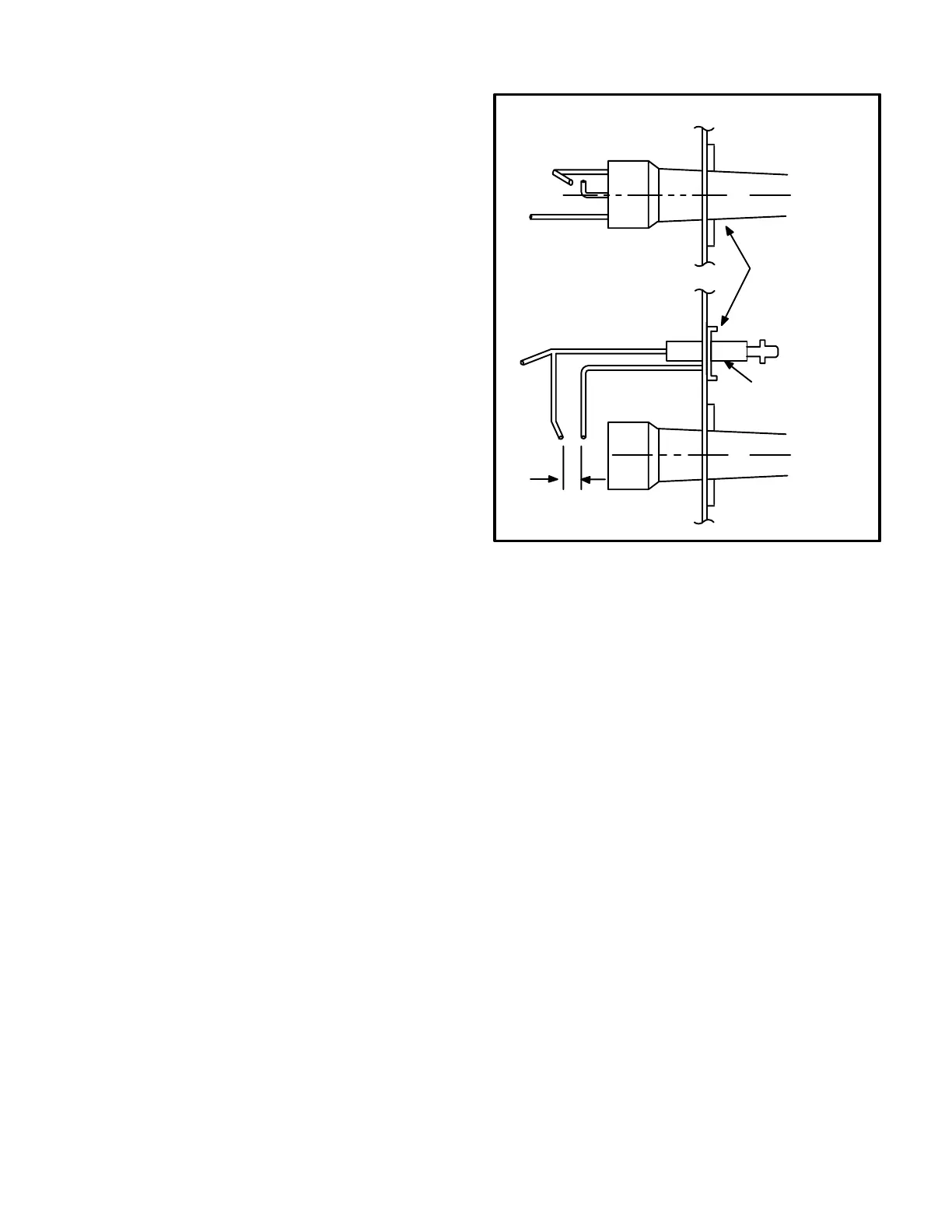

Spark gap may be checked with appropriately sized twist

drills or feeler gauges. Disconnect power to the unit and

remove electrode assembly. The gap should be between

0.094" and 0.156". See figure 35.

DANGER - ELECTRODES ARE NOT FIELD AD

JUSTABLE. ANY ALTERATIONS TO THE ELEC

TRODE MAY CREATE A HAZARDOUS CONDITION

THAT CAN CAUSE PROPERTY DAMAGE OR PER

SONAL INJURY.

N-Flame Sensing

Flame current is an electrical current which passes from

the ignition control through the sensor electrode during

unit operation. The current passes from the sensor

through the flame to ground electrode to complete a safety

circuit. The minimum flame current necessary to keep the

ignitor from lockout is 5 microamps. The electrodes should

be located so the tips are at least 1/2" inside the flame en

velope. Do not bend electrodes. To measure flame cur

rent, follow the procedure below:

1-Disconnect power to unit.

2-Remove lead from sensing electrode and install a

0-50DC microamp meter in series between the

sensing electrode and the sensing lead.

3-Reconnect power and adjust thermostat for heating

demand.

4-When flame is established, meter reading should

be 8 to 20 microamps. Do not bend electrodes.

FIGURE 35

C

L

C

L

GCS16 BURNER / ELECTRODE ASSEMBLY

BURNER

ASSEMBLY

TOP VIEW

SIDE VIEW

IGNITION

ELECTRODE

.094" TO .156"

GAP

5-When finished, disconnect power to unit before dis

connecting meter. Make sure sensor wire is se

curely reconnected before reconnecting power to

unit.

NOTE - If the meter scale reads 0, the leads are re

versed. Disconnect power and reconnect leads for

proper polarity.

O-Combustion Air Blower B6

The combustion air blower, prove switch, connecting hose

and orifice are factory set and are not field adjustable.

However, operation should be monitored to ensure proper

operation. The combustion air blower is used to draw fresh

air into the combustion chamber while simultaneously ex

pelling exhaust gases. The blower operates throughout

the heating cycle. On a heating demand, the combustion

air blower immediately energizes but the ignition control

circuit does not. Once the combustion air blower is ener

gized and moving air through the heat exchanger, the

combustion air prove switch closes to energize the ignition

control. The ignition control then begins attempting igni

tion after 30-40 seconds.

If the combustion air blower does not reach full speed or if

the hose connecting the blower to the prove switch is ob

structed, the prove switch will not close and the ignition

control will not energize.

Loading...

Loading...