Page 40

IMPORTANT - Pay close attention to the order in

which the flue orifice and gaskets are installed.

Inspect all gaskets for deterioration. Replace if neces

sary.

3- Remove the screws holding the blower housing to the

flue box cover plate and wires attached to the motor.

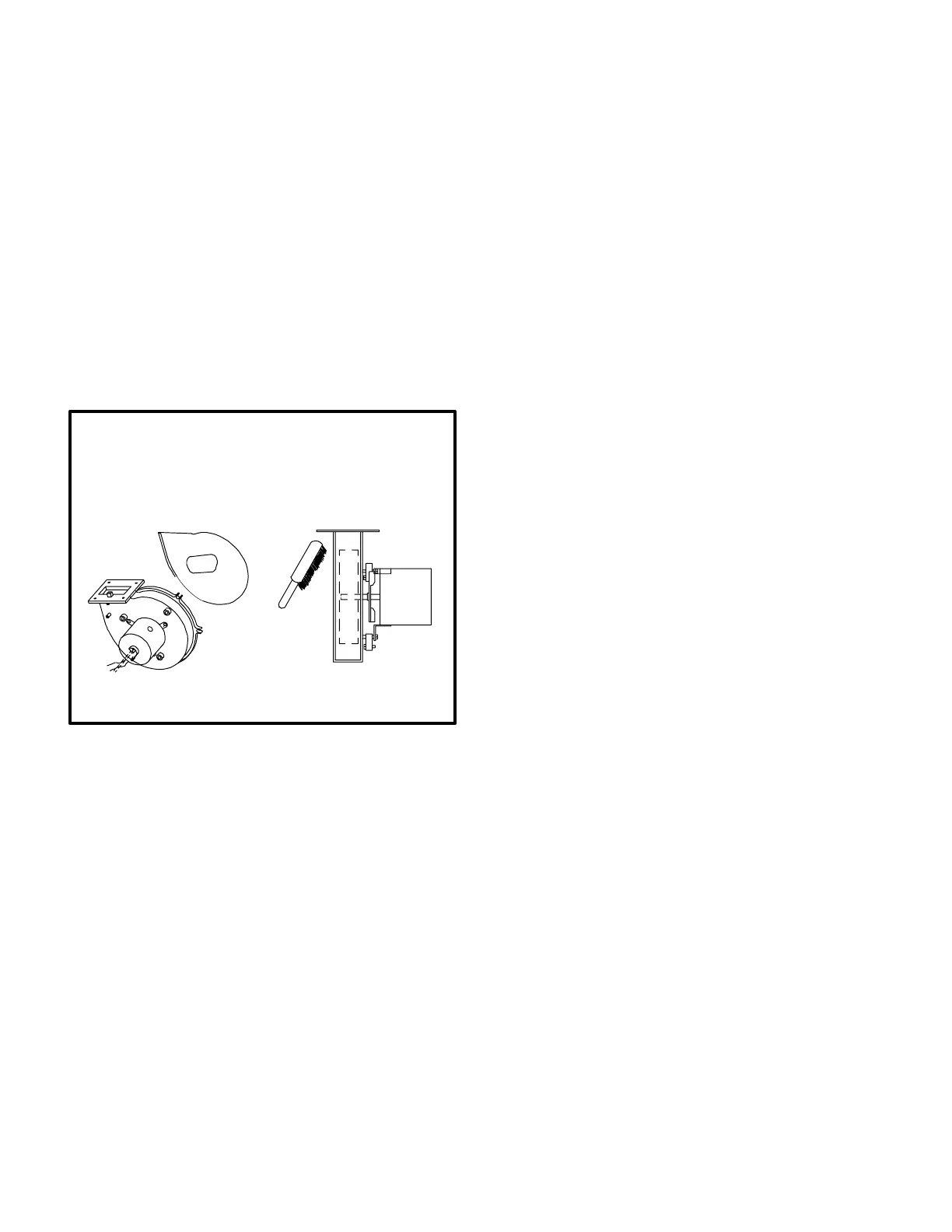

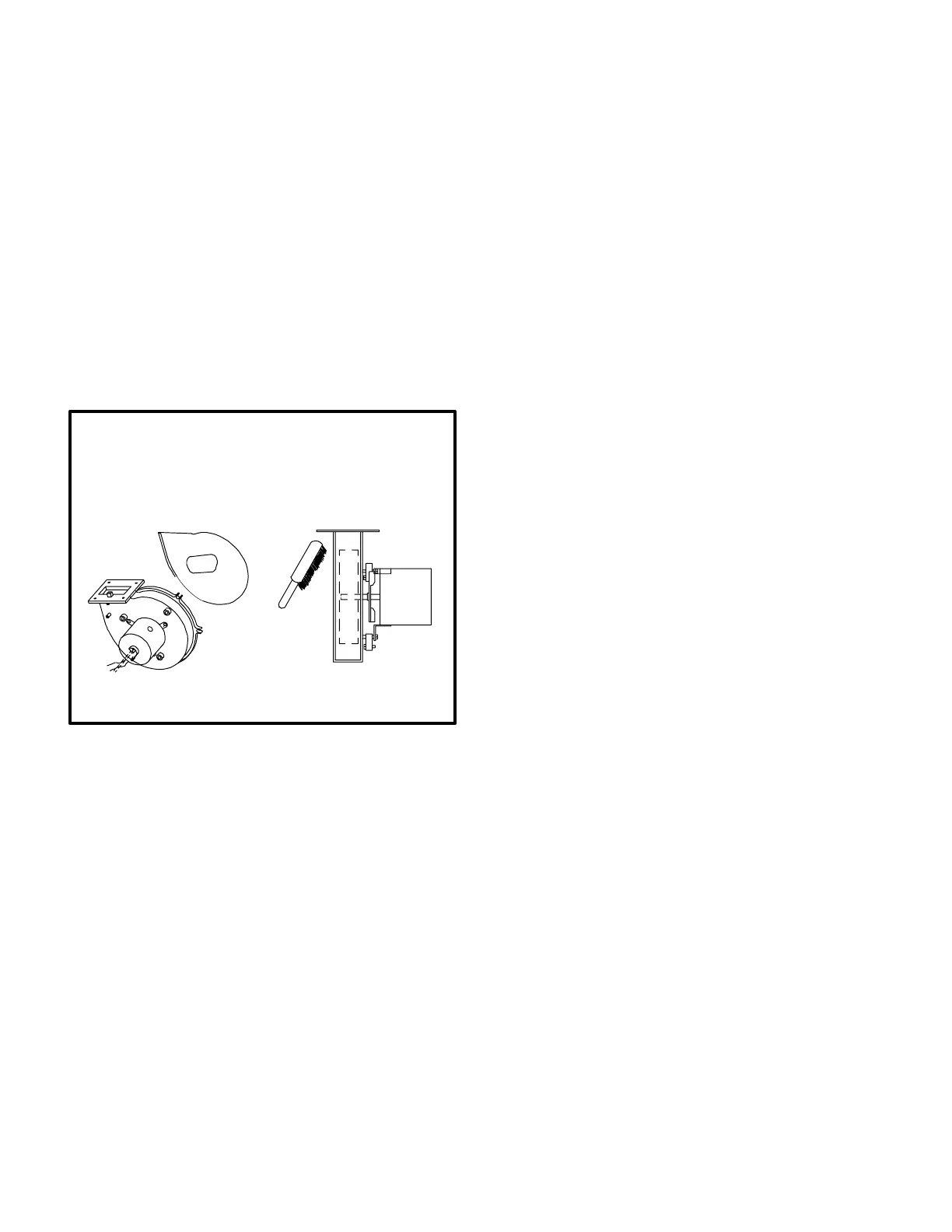

4- If blower can be disassembled (50,000, 75,000, and

100,000 Btuh heat exchangers only), remove blower

backplate as shown in figure 39. Clean blower blades

with a small brush and wipe off any dust from the

housing (see figure 39). Clean any accumulated dust

from inside the flue box cover.

If blower cannot be disassembled (125,000 Btuh heat

exchanger only), clean off any accumulated dust and

reassemble.

FIGURE 39

COMBUSTION AIR BLOWER DISASSEMBLY

CLEAN BLOWER

WHEEL WITH BRUSH.

50, 75, 100 K Btuh UNITS ONLY

REMOVE BLOWER

BACKPLATE

SEAL BACKPLATE WITH HIGH TEMPERATURE

RTV SEALANT WHEN REASSEMBLING

CAUTION - USE CARE WHEN CLEANING COM

BUSTION AIR BLOWER WHEEL. WHEEL IS MADE

OF ALUMINUM AND MAY DISTORT IF TOO MUCH

PRESSURE IS APPLIED.

5- Reassemble combustion air blower by reversing this

procedure. Seal backplate with high temperature RTV

sealant when reassembling.

6- Reconnect tubing connecting blower to flue box. Ar

range tubing so that it can drain accumulated conden

sate.

7- Clean the vestibule panel louvers using a small brush.

F-Flue

Make sure the flue is clean and free of debris.

G-Evaporator Coil

1- Clean coil, if necessary.

2- Check connecting lines and coil for evidence of oil

leaks.

3- Check condensate drain pan and line, if necessary.

H-Condenser Coil

1- Clean and inspect condenser coil. (May be flushed

with a water hose.)

2- Visually inspect connecting lines and coils for evi

dence of oil leaks.

NOTE - If owner complains of insufficient cooling, the unit

should be gauged and refrigerant charge checked. Refer

to Gauge Manifold Attachment, Checking Charge and

Charging sections in this instruction.

I-Electrical

1- Check all wiring for loose connections.

2- Check for correct voltage at unit (unit operating).

3- Check ampdraw on both condenser fan motor and

blower motor.

Fan Motor Rating Plate ____ Actual ________

Indoor Blower Motor Rating Plate____ Actual____

X-ELECTRICAL CONNECTIONS

A-Power Supply

Refer to start up directions and refer closely to the unit wir

ing diagram when servicing. Refer to the unit nameplate

for minimum circuit ampacity and maximum fuse size.

208/460/575 volt units are wired with a red wire connecting

transformer T1 primary to L1. 230 volt units use an orange

wire connecting transformer T1 primary to L1.

B-Field Wiring

Unit and optional control field wiring is shown in the unit

diagram section of this manual.

Loading...

Loading...