Page 18

LGH/LCH036, 048, 060, 072, 074

G-Check Belt Tension

Overtensioning belts shortens belt and bearing life.

Check belt tension as follows:

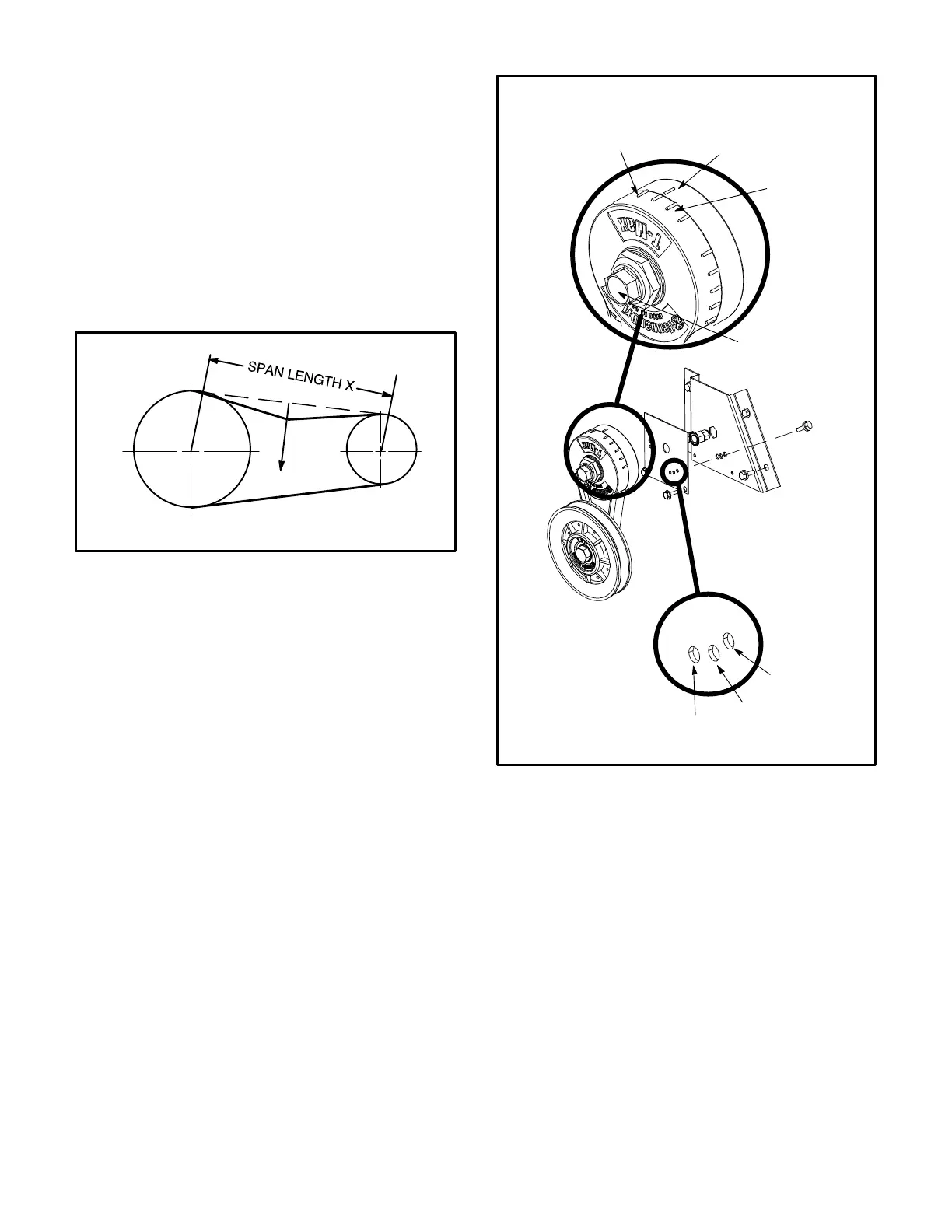

1- Measure span length X. See figure 22.

2- Apply perpendicular force to center of span (X) with

enough pressure to deflect belt 1/64” for every inch

of span length or 1.5mm per 100mm of span length.

Example: Deflection distance of a 40” span would be

40/64” or 5/8”.

Example: Deflection distance of a 400mm span

would be 6mm.

MEASURE BELT TENSION

FIGURE 22

DEFLECTION 1/64” PER INCH OF SPAN

OR 1.5mm PER 100mm OF SPAN

FORCE

3- Measure belt deflection force. For a used belt, the

deflection force should be 5 lbs. (35kPa). A new belt

deflection force should be 7 lbs. (48kPa).

A force below these values indicates an

undertensioned belt. A force above these values

indicates an overtensioned belt.

H-Field-Furnished Blower Drives

For field-furnished blower drives, use page 20 through 44

to determine BHP and RPM required. Reference page 45

to determine the drive kit number. Reference table 9 for

manufacturer's drive numbers.

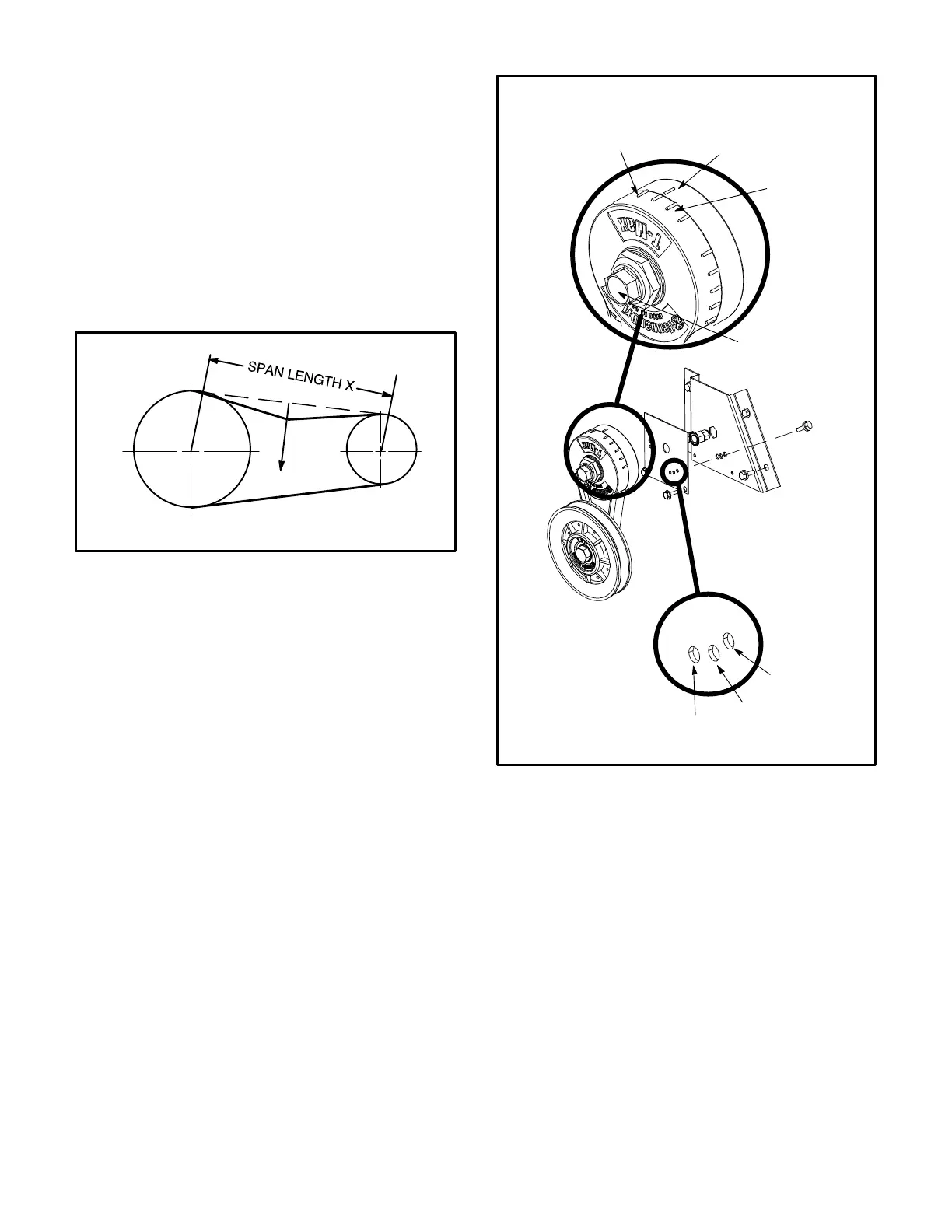

FIGURE 23

ADJUST BELT TENSIONER

MAXIMUM

TENSION

MINIMUM

TENSION

INDICATOR SHOULD BE

BETWEEN MINIMUM AND

MAXIMUM TENSION LINES

FACTORY-SET

POSITION

TIGHTER

BELT

POSITION

TENSIONER

TIGHTEST

BELT

POSITION

BRACKET

TIGHTEN MOUNTING

BOLT TO 22 LB./FT.

USING 9/16” WRENCH

Loading...

Loading...