Page 24

B-Blower Access

1 - Disconnect jack/plug connector to blower motor.

Also disconnect jack/plug connector heating limit

switches on gas units.

2 - Remove screws on either side of blower assembly

3 - Pull base toward outside of unit.

C-Determining Unit CFM

IMPORTANT - Multi-staged supply air units are factory-set

to run the blower at full speed when there is a blower (G)

demand without a heating or cooling demand. Refer to the

eld-provided, design specied CFM for all modes of op-

eration. Use the following procedure to adjust motor pulley

to deliver the highest CFM called for in the design spec.

See Inverter Start-Up section to set blower CFM for all

modes once the motor pulley is set.

1 - The following measurements must be made with

a dry indoor coil. Run blower (G demand) without

a cooling demand. Measure the indoor blower

measurements are taken.

2 -

Blower performance data is based on static pressure

Note - Static pressure readings can vary if not taken

where shown.

3 - See table of contents for Blower Data and or

Optional Accessories. Use static pressure and RPM

readings to determine unit CFM.

4 - The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley

clockwise to increase CFM. Turn counterclockwise

shown in table 4.

TABLE 4

Belt Min Turns Open

A Section No Minimum 5

B Section 1*

*No minimum number of turns open when B belt is used

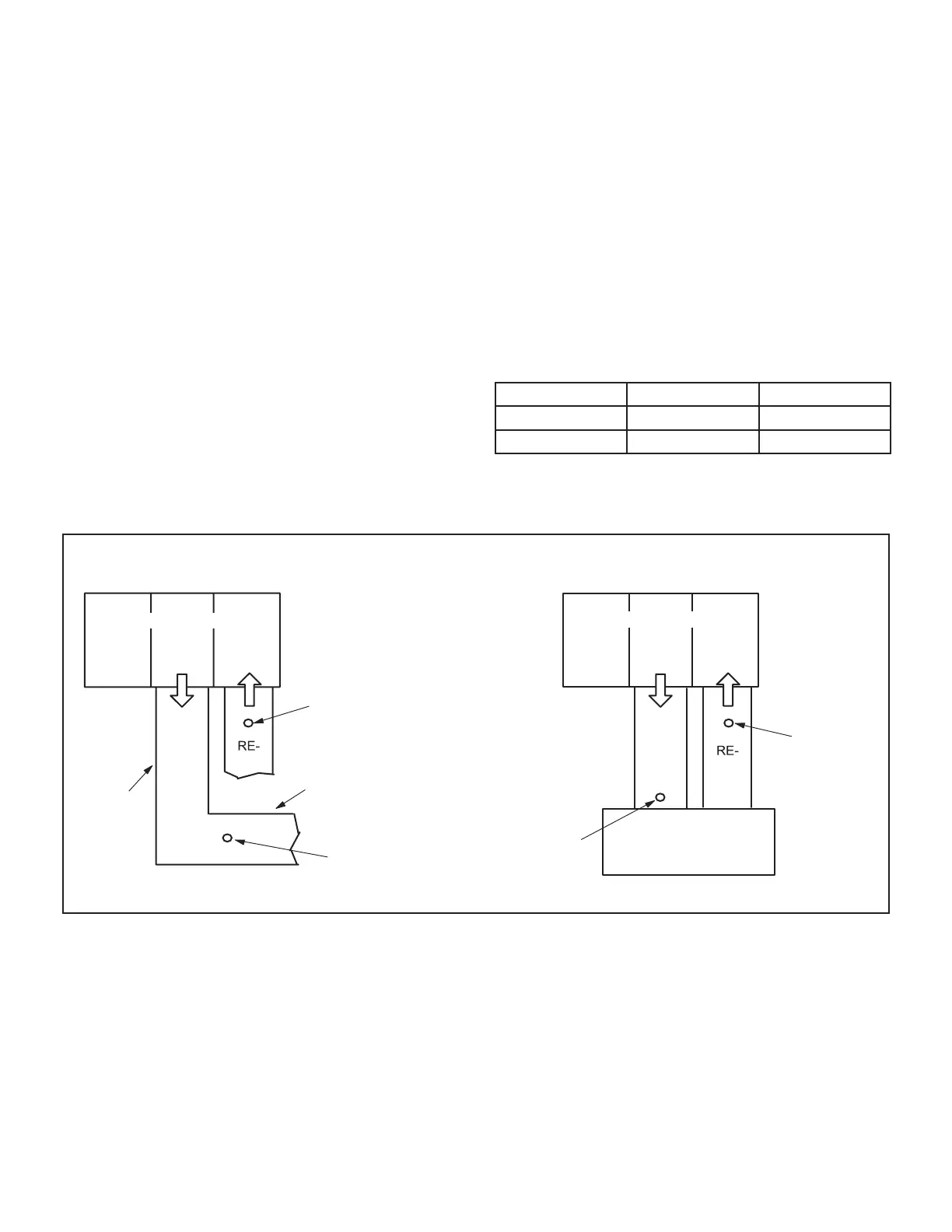

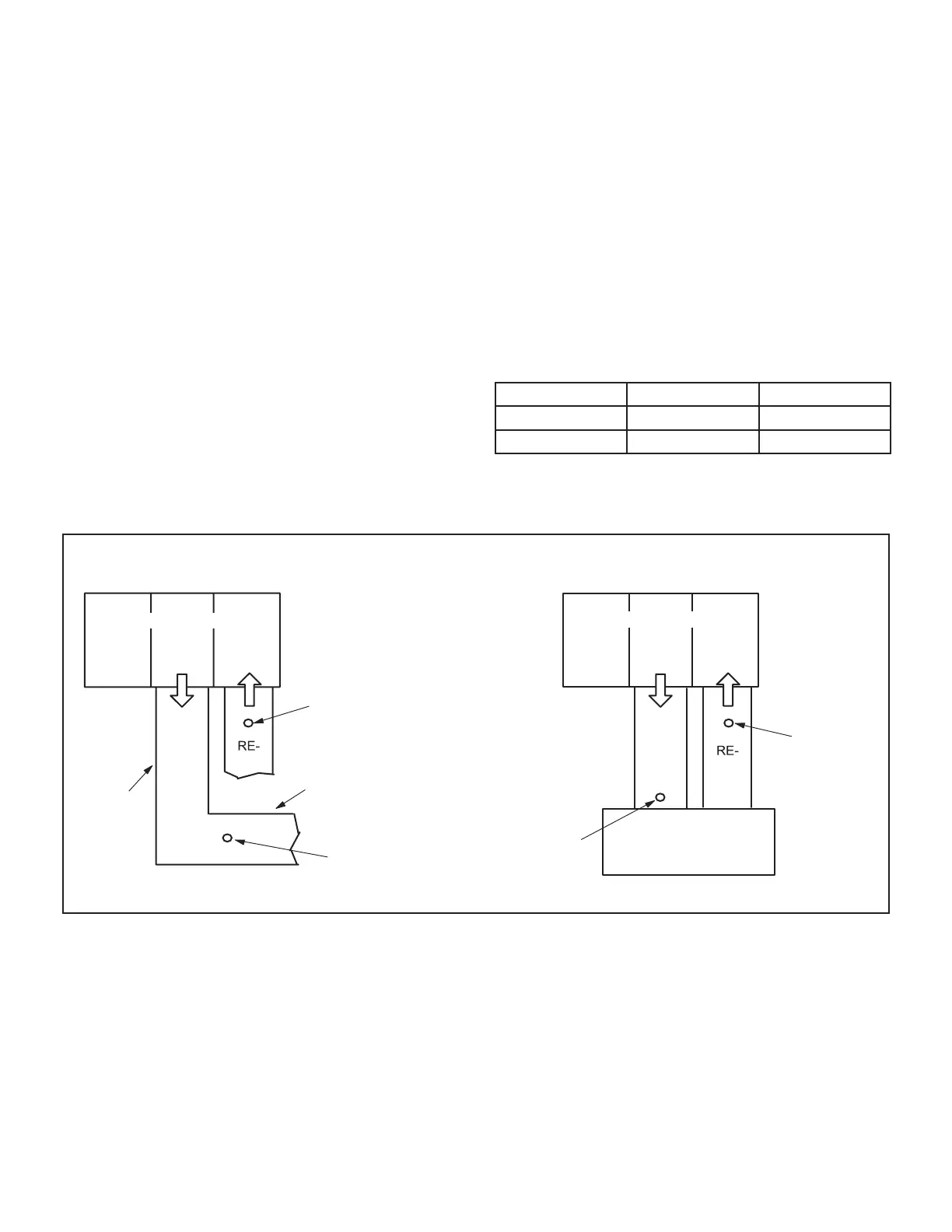

LOCATION OF STATIC PRESSURE READINGS

SUPPLY AIR

READING

LOCATION

SUPPLY

TURN

INSTALLATIONS WITH DUCTWORK

SUPPLY

TURN

INSTALLATIONS WITH CEILING DIFFUSERS

MAIN

DUCT RUN

FIRST BRANCH

OFF OF MAIN RUN

DIFFUSER

ROOFTOP UNIT

ROOFTOP UNIT

SUPPLY AIR

READING

LOCATION

RETURN AIR

READING LOCATION

RETURN AIR

READING

LOCATION

FIGURE 11

Loading...

Loading...