Page 17

Condenser coil may need to be cleaned at startup in

case oil from the manufacturing process is found on the

condenser coil.

Burners

To clean the burners, rst remove them from the furnace

as explained in the Burner and Burner Orice Instructions

section. Vacuum and/or brush as required.

Vent Outlet

Visually inspect vent outlet periodically to make sure that

there is no buildup of soot or dirt. If necessary, clean to

maintain adequate opening to discharge ue products.

Heat Exchanger

With proper combustion adjustment, the heat exchanger

of a gas-red furnace will seldom need cleaning. Sooting

of a gas appliance is highly irregular and once cleaned,

the cause of the sooting must be determined. If the heat

exchanger should become sooted, it can be cleaned as

follows:

1. Remove the burner assembly as outlined in the Burner

and Burner Orice Instructions section.

2. Remove the combustion blower.

3. At the bottom of the heating section, remove the screws

holding the ue collector box. Carefully remove the ue

collector box without ripping the adjacent insulation.

4. Using a wire brush on a exible wand, brush out the

inside of each heat exchanger from the burner inlet

and ue outlet ends.

5. Brush out the inside of the ue collector box.

6. Run the wire brush down the heat exchanger tubes

from the ue collector end.

7. If soot buildup is excessive, remove the vent motor and

clean the wheel and housing. Run the wire brush down

the ue extension at the outlet of the vent housing.

8. After brushing is complete, blow all brushed areas with

air. Vacuum as needed.

9. Replace parts in the reverse order they were removed

in Steps 1 through 3.

10. When replacing the ue collector box, be careful so as

not to tear the adjoining insulation.

11. Assure that all joints on the vent side of the combustion

system are air tight. Apply a high temperature (+500°F)

sealing compound where needed.

Control System Diagnostics

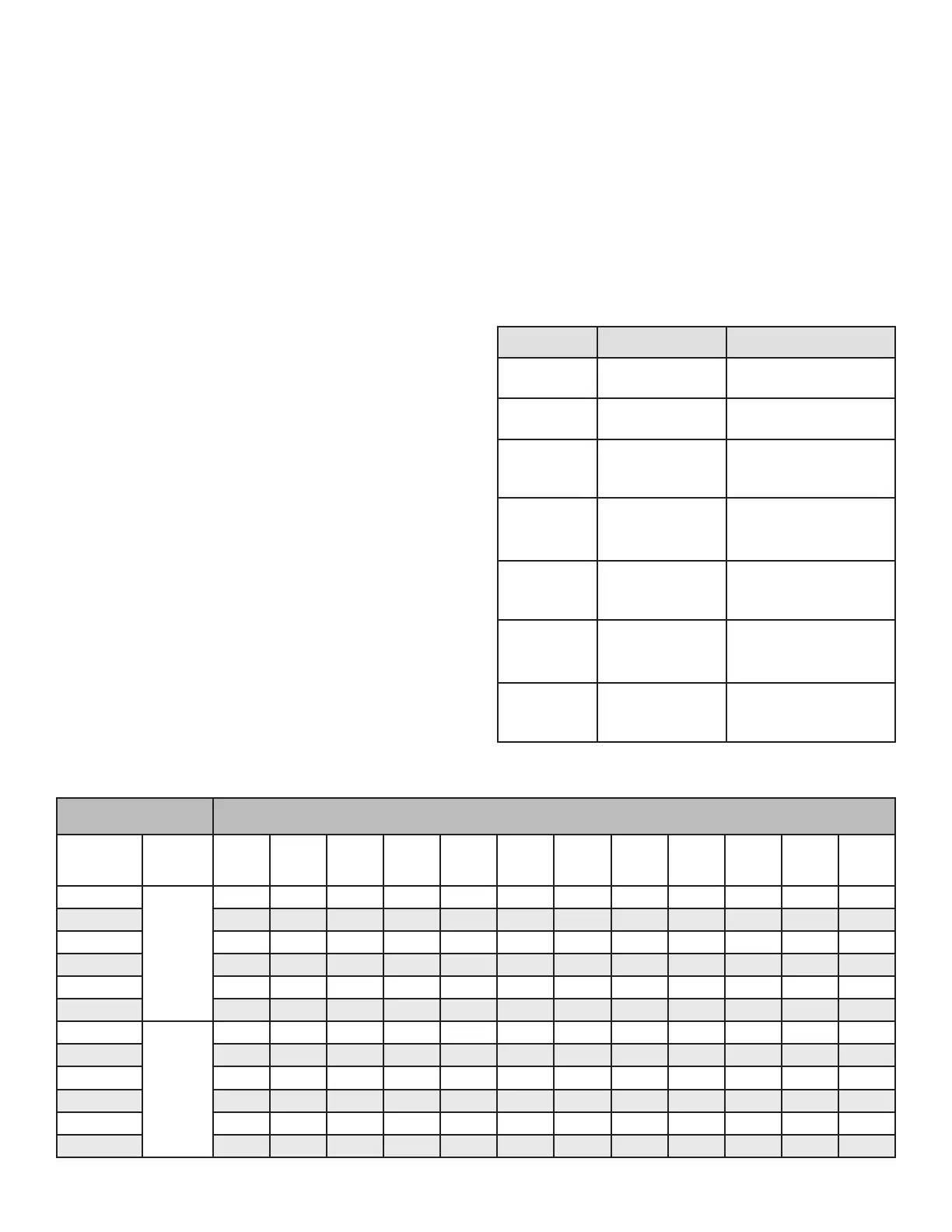

Table 4. Fault Codes

LED Status Flashing Rate Fault Description

Slow Flash

One ash per

second

Normal operation:

No call for heat

Fast Flash

Two ashes per

second

Normal operation:

Call for heat

2 Flash

Two ashes in

second with

1-second pause

System lockout:

Failed to detect or

sustain ame

3 Flash

Three ashes in

1.5 seconds with

1-second pause

Pressure switch senses

incorrect pressure or gas

valve coil is open.

4 Flash

Four ashes in

2 seconds with

1-second pause

High limit or rollout

switch open

5 Flash

Five ashes in

2.5 seconds with

1-second pause

Flame sensed and gas

valve not energized

Steady --

Internal failure:

Micro-controller failure;

self-check

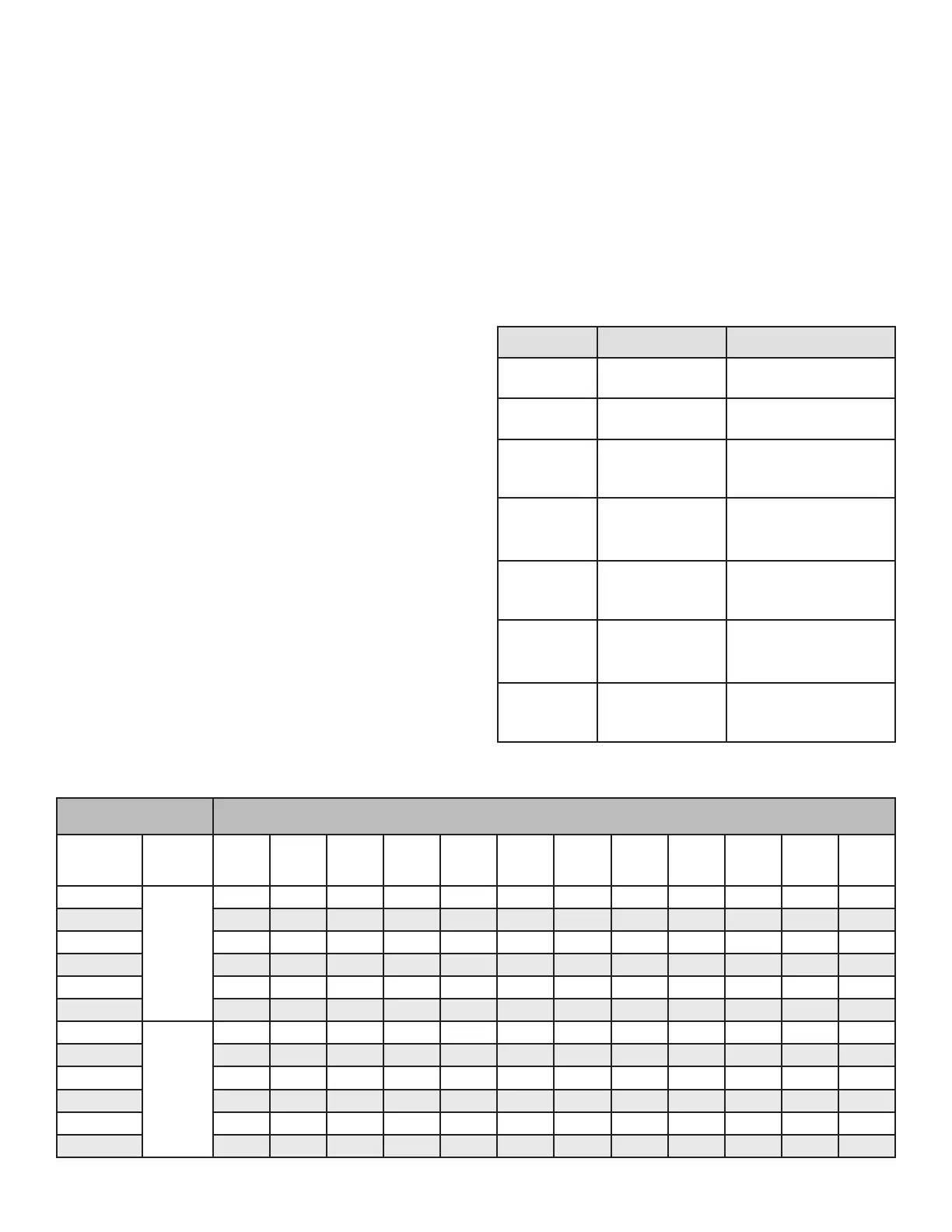

Table 5. Cooling Performance - Gas/Electric Models

80 DB / 67 WB Deg.

Return Air

Air Temperature Entering Evaporator Coil, Degree F

Cooling

Input

(1000 BTU)

Pressure 65° 70° 75° 80° 82° 85° 90° 95° 100° 105° 110° 115°

24

Suction

135 136 137 139 139 141 143 146 148 150 152 154

30 135 137 140 142 143 145 147 150 152 154 155 157

36 135 137 140 142 143 144 147 149 151 152 154 155

42 129 132 135 139 140 141 143 145 146 147 148 149

48 132 136 139 143 144 145 146 147 149 151 152 154

60 130 131 133 134 135 136 139 141 144 146 149 152

24

Liquid

250 266 282 298 304 318 340 363 388 413 438 463

30 247 269 292 314 323 336 358 380 406 432 457 483

36 250 275 301 326 336 351 375 399 423 446 470 493

42 248 271 293 316 325 339 362 385 411 436 462 487

48 265 286 308 329 338 352 376 400 427 455 482 509

60 256 276 296 316 324 340 365 386 415 438 473 503

Loading...

Loading...