Page 47

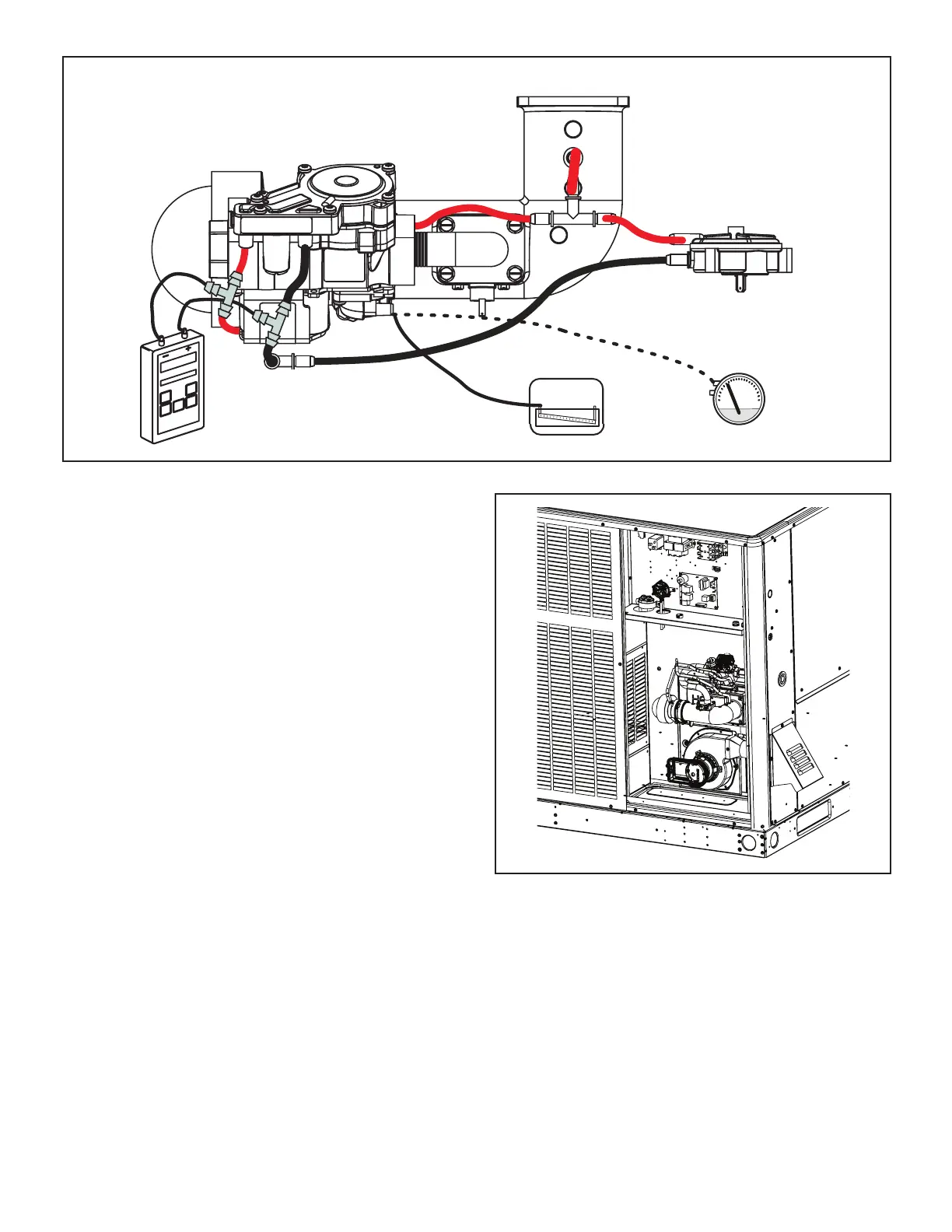

Operating Signal Pressure and Manifold Pressure Measurement

+_

or

High

Low

Signal Pressure

Manifold Pressure

FIGURE 26

Manifold Pressure

A unit’s Manifold Pressure is the product of the Signal

Pressure x the Gas Valve’s Amplication Factor (MP = ∆P

x AF). If the manifold pressure is not within specication,

it will be helpful to determine if it is the Signal Pressure or

the Amplication Factor that is the culprit. The amplica-

tion factor is 4.0 ± 20% (so 3.2 – 4.8). Typical gas valves

that we have encountered during development seem to

range between 3.8 and 4.2.

Condition: Signal Pressure Amplication Factor Man-

ifold Pressure Notes

• Nominal 0.72 4.0 2.9

• Low Amp 0.72 3.8 2.7 Not full AF tolerance range

• High Amp 0.72 4.2 3.0 Not full AF tolerance range

• Low Signal 0.67 4.0 2.7

• High Signal 0.77 4.0 3.1

• Both Low 0.67 3.8 2.6 Not full AF tolerance range

• Both High 0.77 4.2 3.2 Not full AF tolerance range

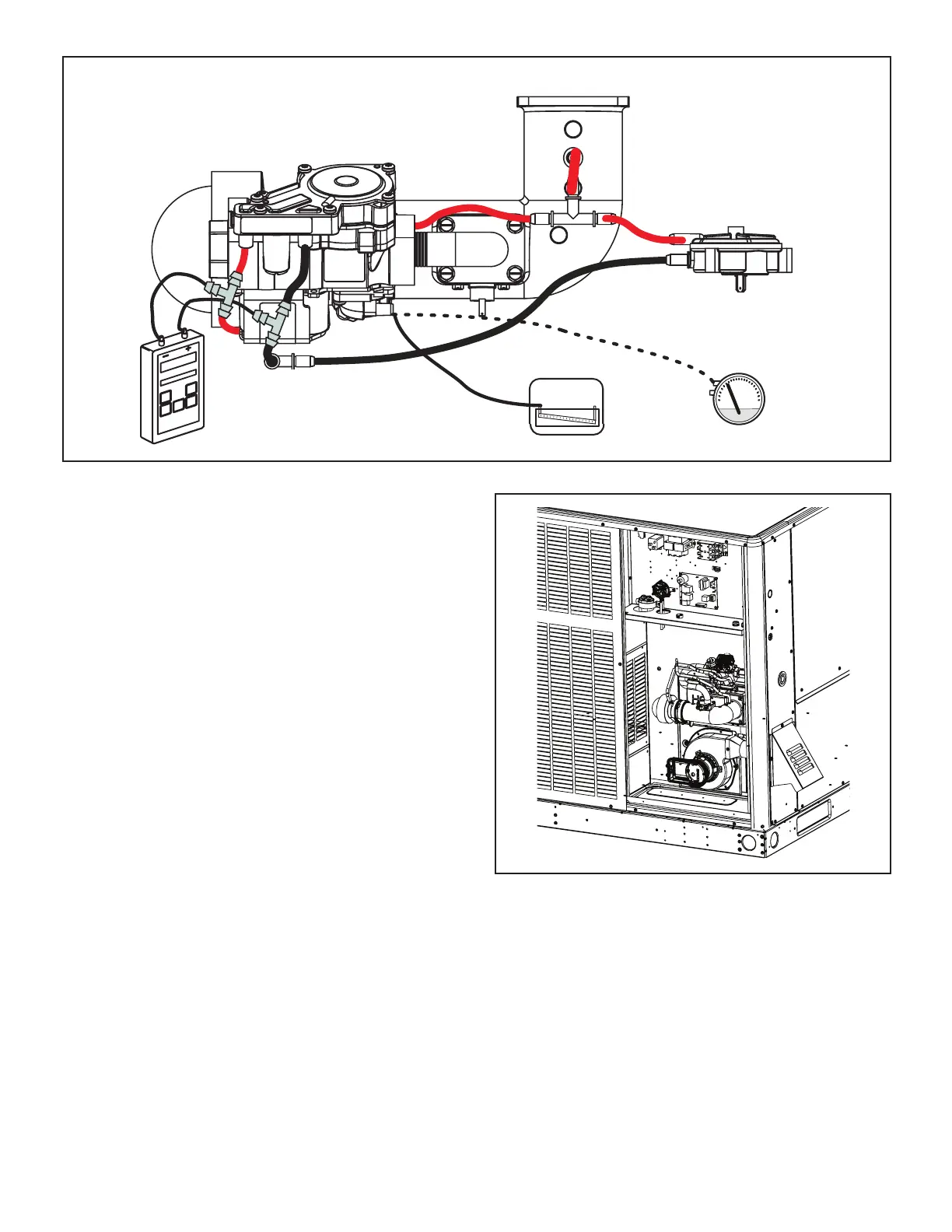

FIGURE 27. Typical Heating Parts Arrangement

Post-Start Checklist

After the entire control circuit has been energized and the

heating section is operating, make the following checks:

1 - Check for gas leaks, using soapy solution, in the

unit piping as well as the supply piping.

2 - Check the supply gas pressure. It must be within the

limits shown on the rating plate. Supply pressure

should be checked with all gas appliances in the

building at full re. At no time should the standby

gas pressure exceed 13” w.c., nor the operation

pressure drop below 5” w.c. for natural gas units. If

gas pressure is outside these limits, contact the gas

supplier for corrective action.

Loading...

Loading...