Installation - Operation - Maintenance manual (IOM) • AIR COOLED CHILLERS & SPLIT UNITS - 1106-E • 36 •

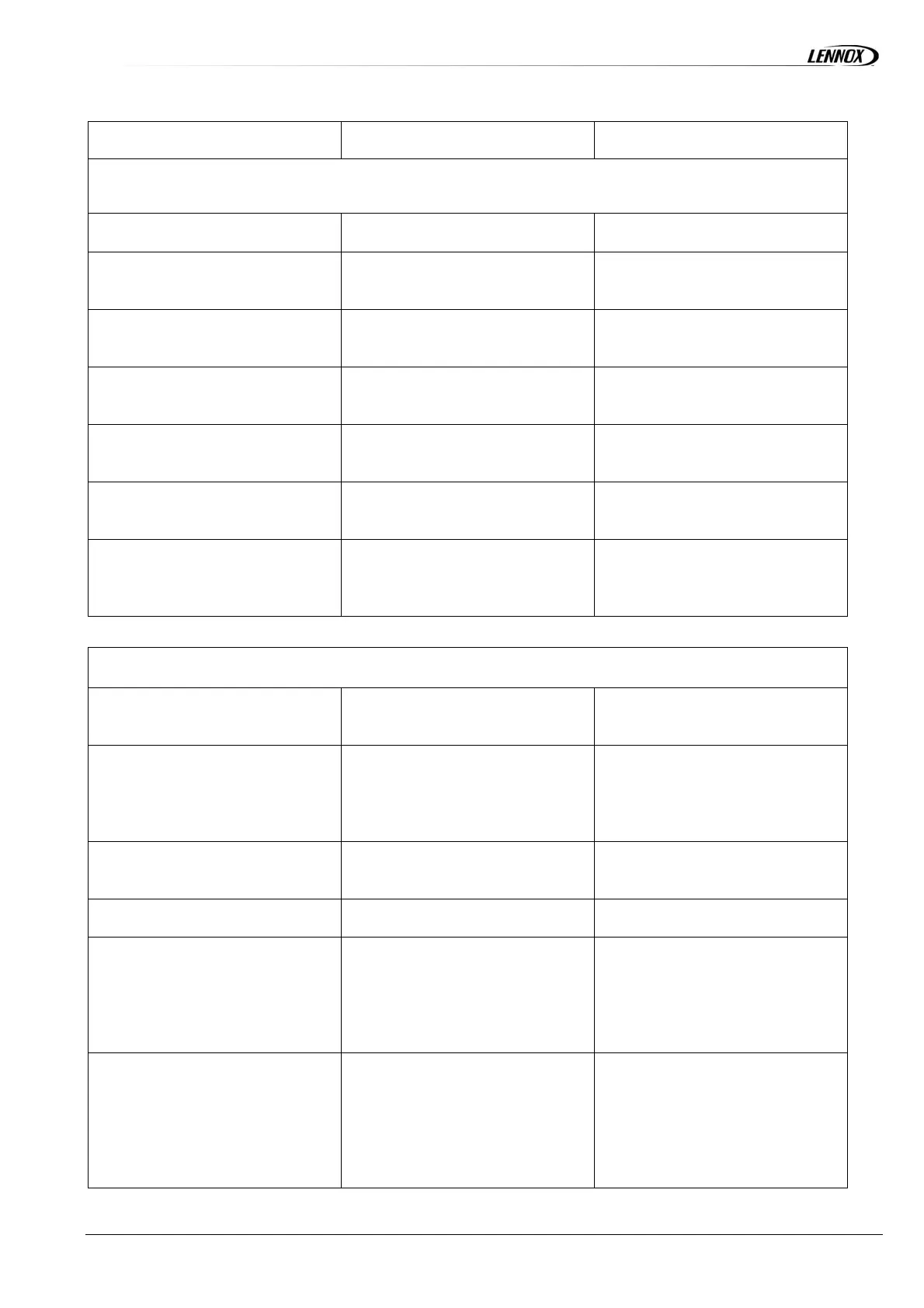

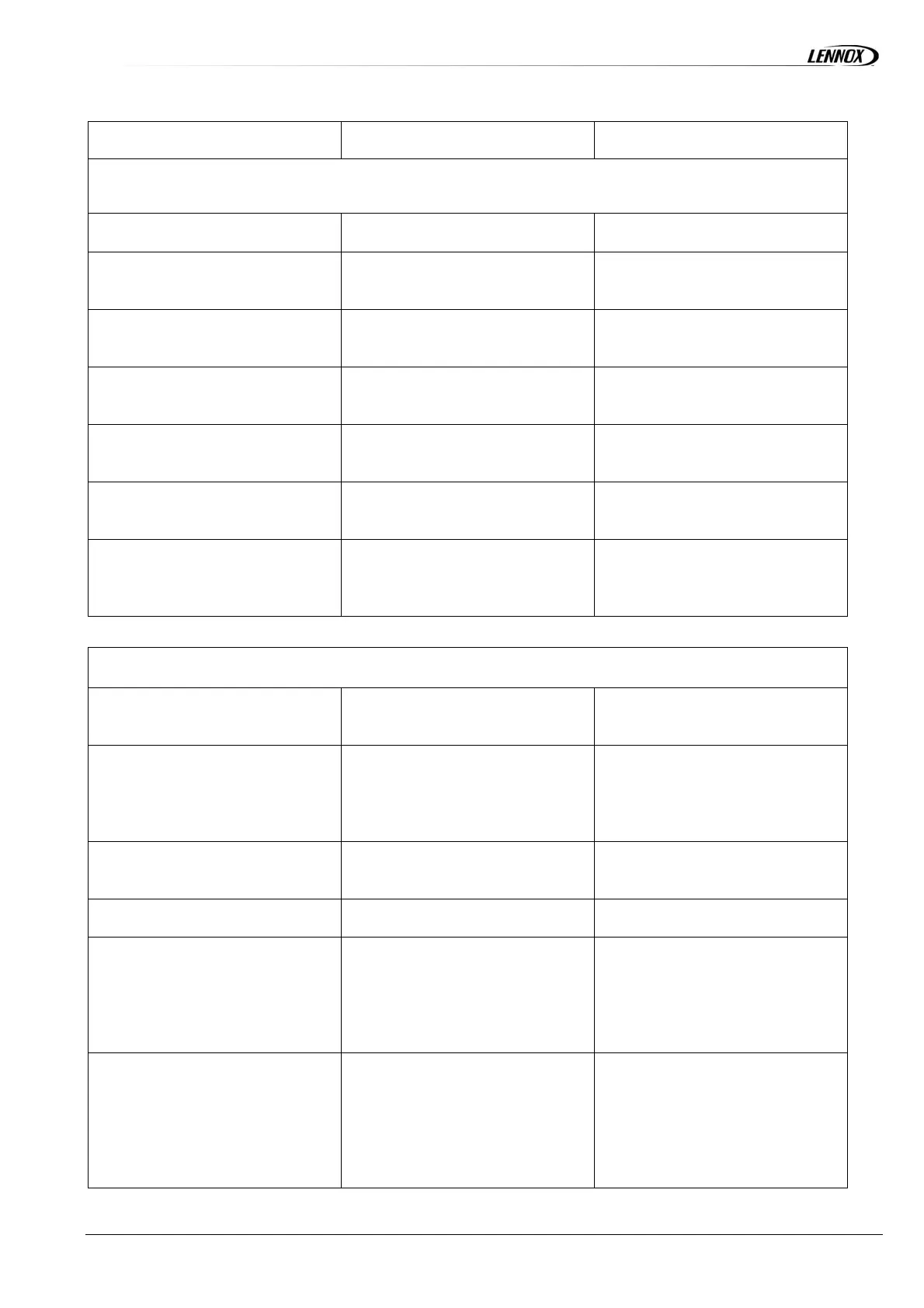

8.1 LIST OF THE MOST COMMON PROBLEMS – CONTINUED

PROBLEMS – SYMPTOMS

PROBABLE CAUSE

RECOMMENDED ACTION

D) THE COMPRESSOR RUNS IN LONG CYCLES OR RUNS CONTINOUSLY

- Faulty control thermostat - Check operation

- Temperature too low in the

conditioned space

- Chilled water thermostat set too low - Adjust it

- Bubbles in sightglass - Low refrigerant charge

- Check the refrigerant charge in the

sightglass and top up if necessary

- Filtrer-drier partly obstructed

- Check the drier and replace as

required, change the filter cartridge

- Expansion valve partly closed

- Check expansion valve bulb and

capillary, measure superheat

- Liquid line valve not open far

enough

- Open the valve completely

- Noisy compressor, or abnormally

high suction pressure or low

discharge pressure

- Leaky compressor valves

- Check valve gas-tightness, replace

the valve plate if necessary. Tighten

compressor nuts and bolts

E) THE COMPRESSOR CUTS OUT ON OIL PRESSURE SAFETY SWITCH

- Oil pressure switch tripped

- Check operation of the oil pressure

safety switch

- Oil level in sightglass is too low - Oil pressure too low

- Check the oil level in the sightglass

on the crankcase, check the

cleanliness of the oil filter, check the

oil pump

- Visible oil leak / Oil level too low - Low oil charge

- Check that there is no leakage and

add oil

- Leaky oil sump - Repair and add oil

- Suction line unusually cold,

compressor noisy

- Liquid refrigerant present in the

compressor crankcase

- Check appearance of the oil in the

sightglass. Measure temperature of

the oil pump, measure superheat at

the expansion valve, check that the

valve bulb is tightly attached

- Poor heat exchange in the

evaporator

- Check water flow. Check fouling by

measuring the water pressure drop.

Excessive oil migration in the circuit

: measure evaporating pressure,

superheat and the temperature of

the oil pump

Loading...

Loading...