Installation - Operation - Maintenance manual (IOM) • AIR COOLED CHILLERS & SPLIT UNITS - 1106-E • 38 •

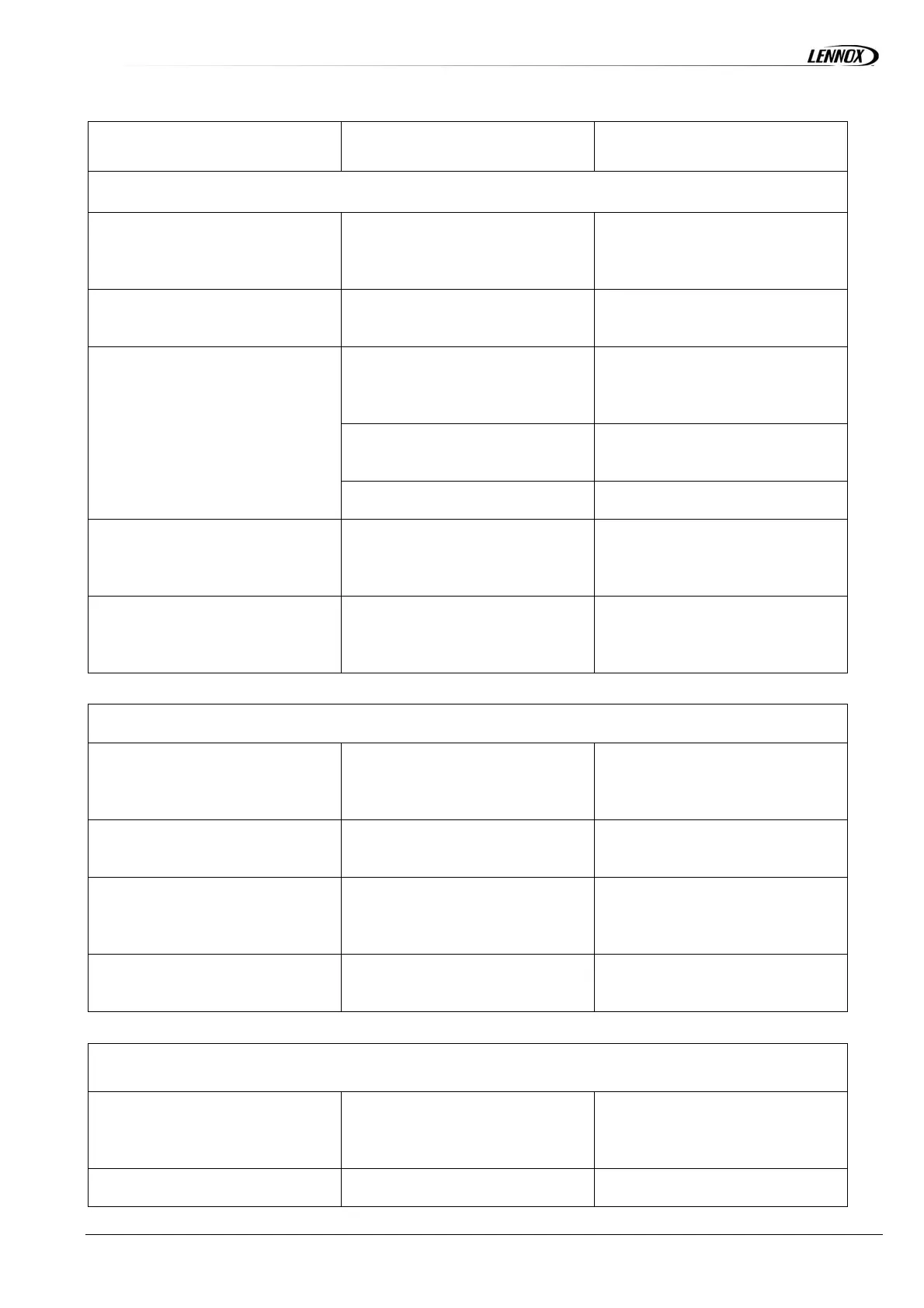

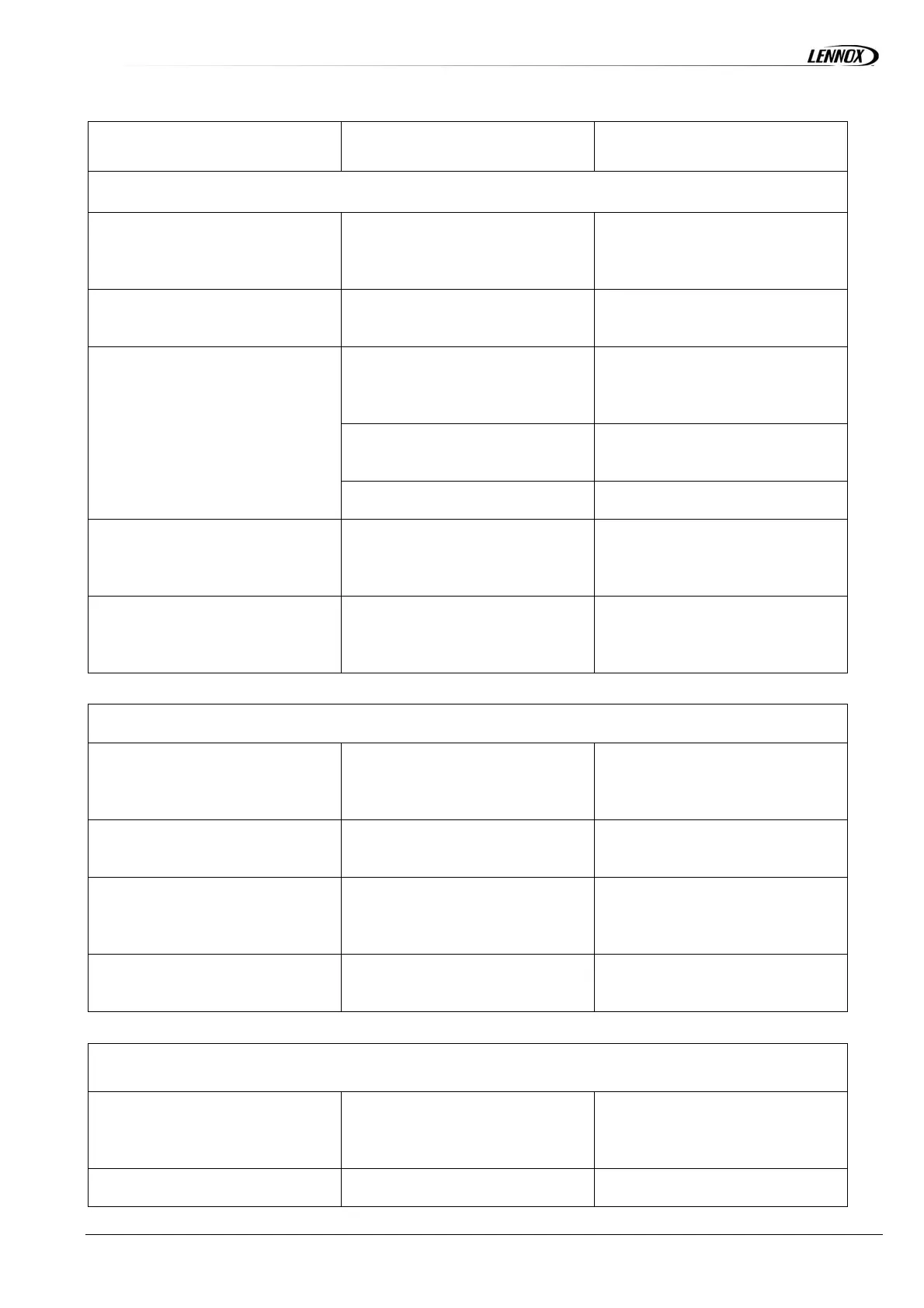

8.1 LIST OF THE MOST COMMON PROBLEMS – CONTINUED

PROBLEMS – SYMPTOMS

PROBABLE CAUSE

RECOMMENDED ACTION

J) THE COMPRESSOR IS NOISY

- If starting on a single winding on

compressors fitted with part winding

start or wye-delta

- Check operation of the starter

contacts, the start up time delay and

the condition of the windings

- Compressor knocking

- Broken mechanical parts inside

compressor

- Replace the compressor

a) Liquid slugging

a) Check superheat and that the

expansion valve bulb is correctly

installed

b) Expansion valve blocked in open

position

b) Repair or replace

- Suction line is unusually cold

- Broken suction valves - Replace broken valves

- High discharge pressure. The water

regulating valve or the pressure

operated water valve taps or knocks

- Pressure operated water valve

fouled, water pressure is to high or

irregular

- Clean the valve. Install and

expansion tank upstream of the

valve

- Compressor shuts down through

action of the oil pressure safety

switch

- Low oil charge - Add oil

K) DISCHARGE PRESSURE TOO HIGH

- Water is far too hot at condenser

outlet

- Water flow to low or water

temperature too high in the

condenser

- Adjust the pressure operated water

valve or the thermostat on the

cooling tower

- Water is far too cold at the

condenser outlet

- Condenser tubes fouled - Clean the tubes

- Condenser abnormally hot

- Presence of air or incondensibles in

the circuit, or excessive refrigerant

charge

- Purge incondensibles and/or air,

and recover excess refrigerant

- Chilled water leaving temperature

too high

- Excessive cooling load

- Reduce load, reduce water flow if

necessary

L) DISCHARGE PRESSURE IS TOO LOW

- Water is very cold at condenser

outlet

- Condenser water flow too high or

water temperature is too low

- Adjust the pressure operated water

valve or the thermostat on the

cooling tower

- Bubbles in sightglass - Low refrigerant charge - Repair the leak and add refrigerant

Loading...

Loading...