Installation - Operation - Maintenance manual (IOM) • AIR COOLED CHILLERS & SPLIT UNITS - 0105-E • 62 •

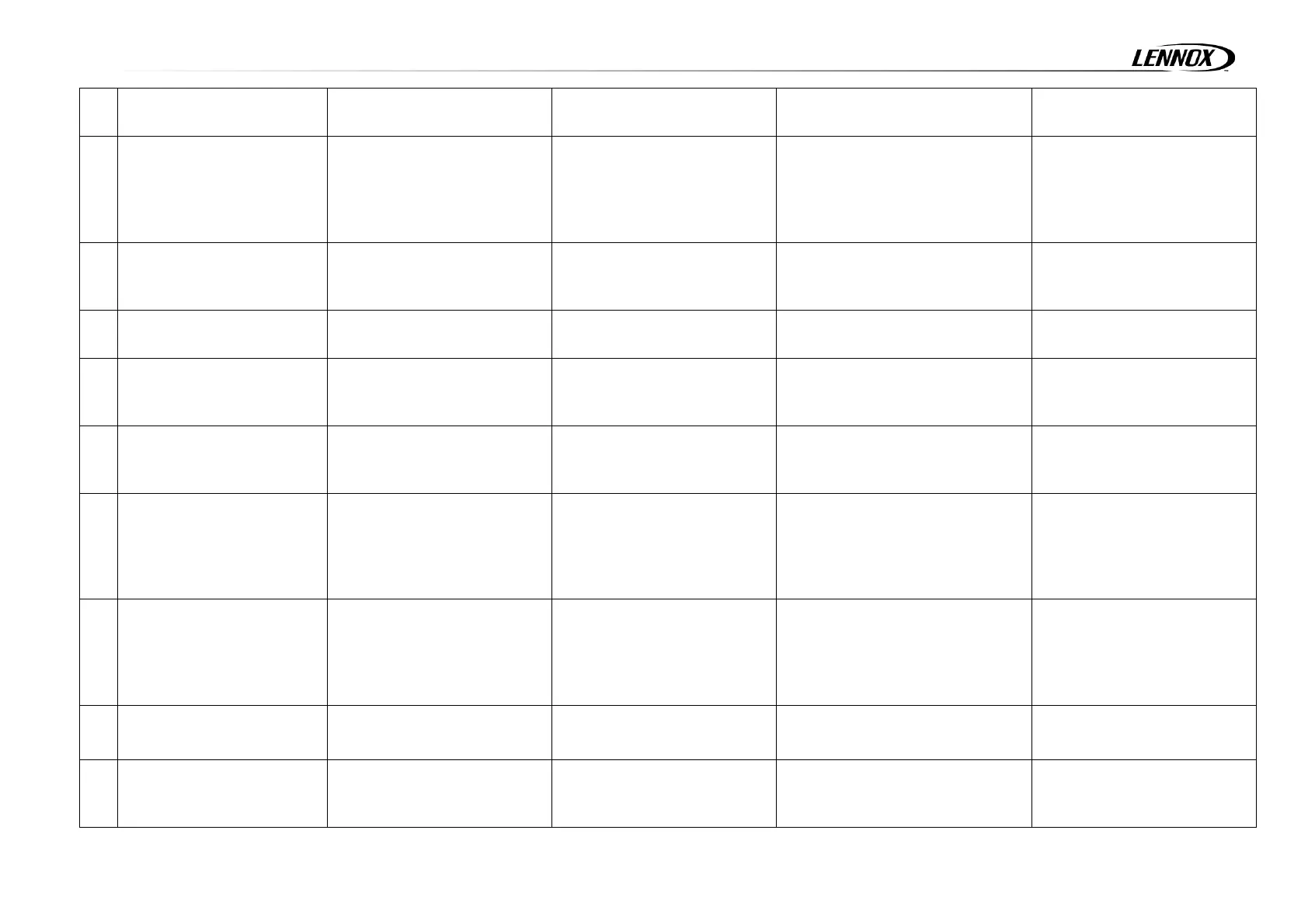

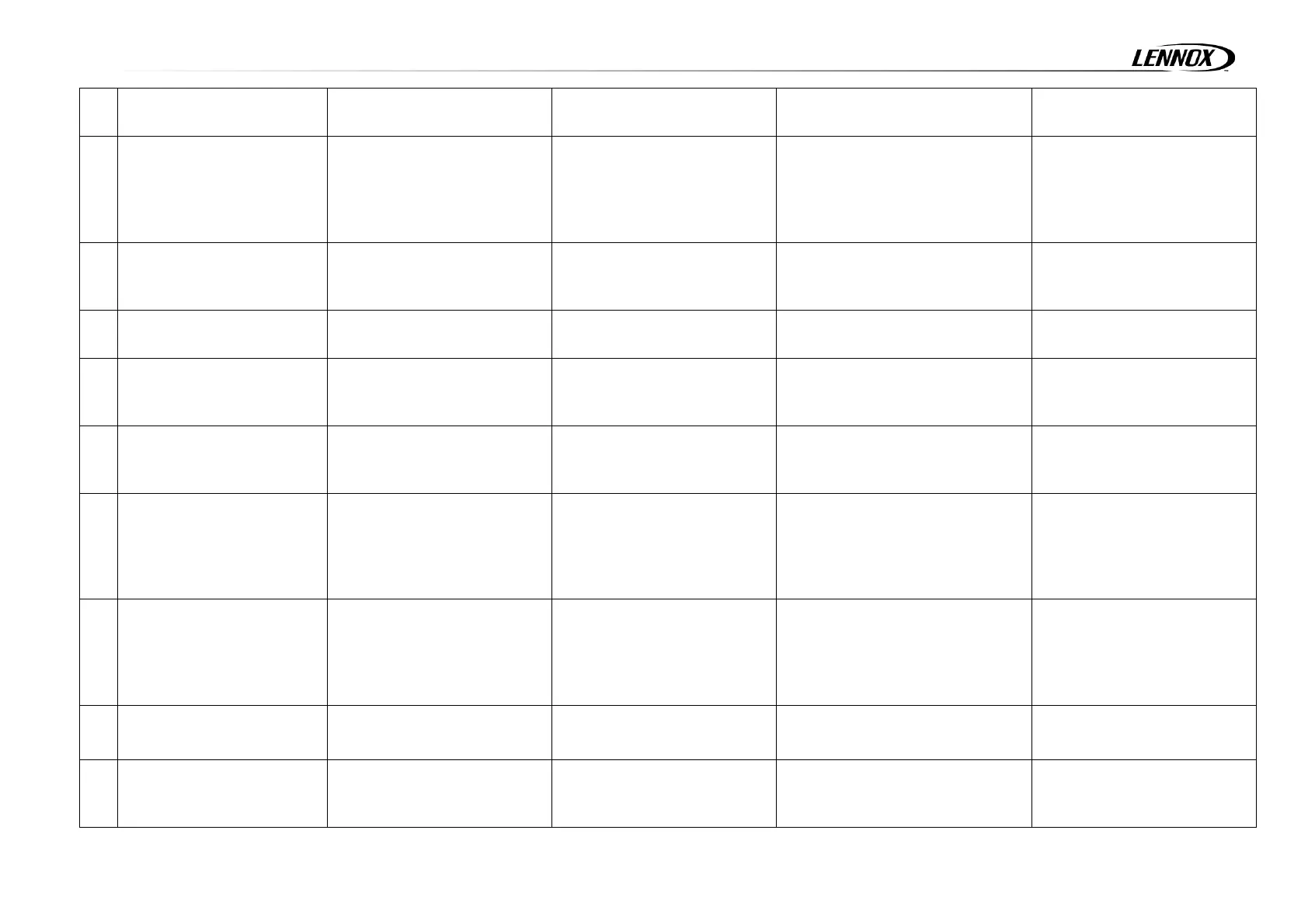

N°

Event

Effect

Risk

Actions to Eliminate the Risk

Information to minimise the

Occurrence of a risk

8A

Unit exposed to extremely

corrosive materials.

Modification of the mechanical

and chemical properties of certain

materials with a risk or corrosion

rupture, pipe bursting, leaks and

cracks.

Partial or complete destruction of

the circuit, liquid/gas/metal parts

could be thrown out of the unit

Protect the units against these types of

products

Indications in the technical IOM

supplied

9A

Unit exposed to explosive

materials.

Risk of explosion or pipe bursting.

Partial or complete destruction of

the circuit, liquid/gas/metal parts

could be thrown out of the unit

Protect the units against these types of

products

Indications in the technical IOM

supplied

10A

Inappropriate Heat Transfer

Fluid

Corrosion, excessive heat

Partial or complete destruction of

the circuit. Leaks

Usual fluids are Water or Water with

Glycol.

Indications in the technical IOM

supplied

11A

Inappropriate refrigerant fluid in

the circuit

Corrosion, excessive heat,

combustion or explosion

Partial or complete destruction of

the circuit, liquid/gas/metal parts

could be thrown out of the unit

Only use the fluid specified on the

unit’s nameplate.

Indications of the refrigerant fluid

on the unit nameplate

12A

Inappropriate oil in the

compressor

Corrosion, excessive heat,

Partial or complete destruction of

the circuit. Leaks

Authorized oils: Refer to the

compressor nameplate or the

documentation.

Indication on the compressor

nameplate or the manufacturer

documentation.

13A

Working on a part under

pressure

Risk of explosion or part bursting

away from the machine.

Liquid/gas/metal parts could be

thrown out of the unit

Isolate the section of the circuit to be

worked on and recover the refrigerant

before any work.

Always wear protection goggles and

gloves.

Indications in the technical IOM

supplied

14A

Brazing or un-brazing parts

from the circuit

Strains, cracks, pipe

bursting

Partial or complete destruction of

the circuit, liquid/gas/metal parts

could be thrown out of the unit

Parts to be brazed using best

engineering practices. Use brazing

materials approved by Lennox. Ensure

the circuit is leak free before refilling

with refrigerant.

Indications in the technical IOM

supplied

15A

Unit exposed to inductive

interferences

Corrosions, cracks

leaks

Ensure the unit is earthed properly

Indications in the technical IOM

supplied

16A

Unit exposed to internal or

external vibrations

Strains, cracks, explosions

Partial or complete destruction of

the circuit, liquid/gas/metal parts

could be thrown out of the unit

Inspect the unit regularly

Indications in the technical IOM

supplied

Loading...

Loading...