Installation - Operation - Maintenance manual (IOM) • AIR COOLED CHILLERS & SPLIT UNITS - 0105-E • 19 •

tightened in the various wells, if necessary add heat conducting paste to improve contact. Make sure all sensors

are correctly fitted and that all capillary tubes are fastened.

The technical data printed at the top of the wiring diagram should correspond with those indicated on the unit

nameplate.

3) Make sure that the power supplied to the unit corresponds to its operating voltage and that phase rotation

corresponds to the direction of rotation of the compressors (screw & scroll).

4) Make sure that the water circuits mentioned in 1 are completely filled with water or brine as the case may be;

with the air bled out of all high points, including the evaporator ensuring they are perfectly clean and leaktight.

In the case of machines with water cooled condensers, the condenser water circuit must be ready to operate,

filled with water, pressure tested, bled, filter cleaned after 2 hours of operation of the water pump. Cooling tower

in operating condition, water supply and overflow checked, fan in operating condition.

5) Reset all manually resetting safety devices (where necessary).

Open power circuits to all components: compressors, fans....

6) Power up the unit with the main disconnect switch (option). Visually check the oil level in the compressor

crankcases (bullseyes). This level may vary from one compressor to another, but should never be higher than

the first third of the way up the bullseyes.

CAUTION : Power up the compressor crankcase heaters at least 24 hours before starting the unit. This will

enable the refrigerant in the crankcases to evaporate off, and prevents damage to compressors through lack

of lubrication during start up.

7) Start the pump(s) check the flow of liquid to be cooled through the heat exchangers: note the inlet and outlet

water pressures, and, using the pressure drop curves, calculate liquid flow by applying the following formula:

actual flow

1/21 PPxQQ =

where

P2 = pressure drop measured on site

P1 = pressure drop published by LENNOX for a liquid flow of Q1

Q1 = nominal flow

Q = real flow

8) On units with air cooled condensers, check for correct operation of the fans and that the protective grilles are

in good condition. Make sure that rotation is in the right direction.

9) On units with ducted fan, check the air flow and duct pressure drop.

On delivery, the drive belts are new and correctly tensioned. After the first 50 operating hours check and adjust

the tension. 80% of the total elongation of belts is generally produced during the first 15 hours of operation.

Before adjusting the tension, make sure that the pulleys are correctly aligned.

To tension the belt, set the height of motor support plate by moving the plate adjustment screws.

The recommended deflection is 16 mm per metre from centre to centre.

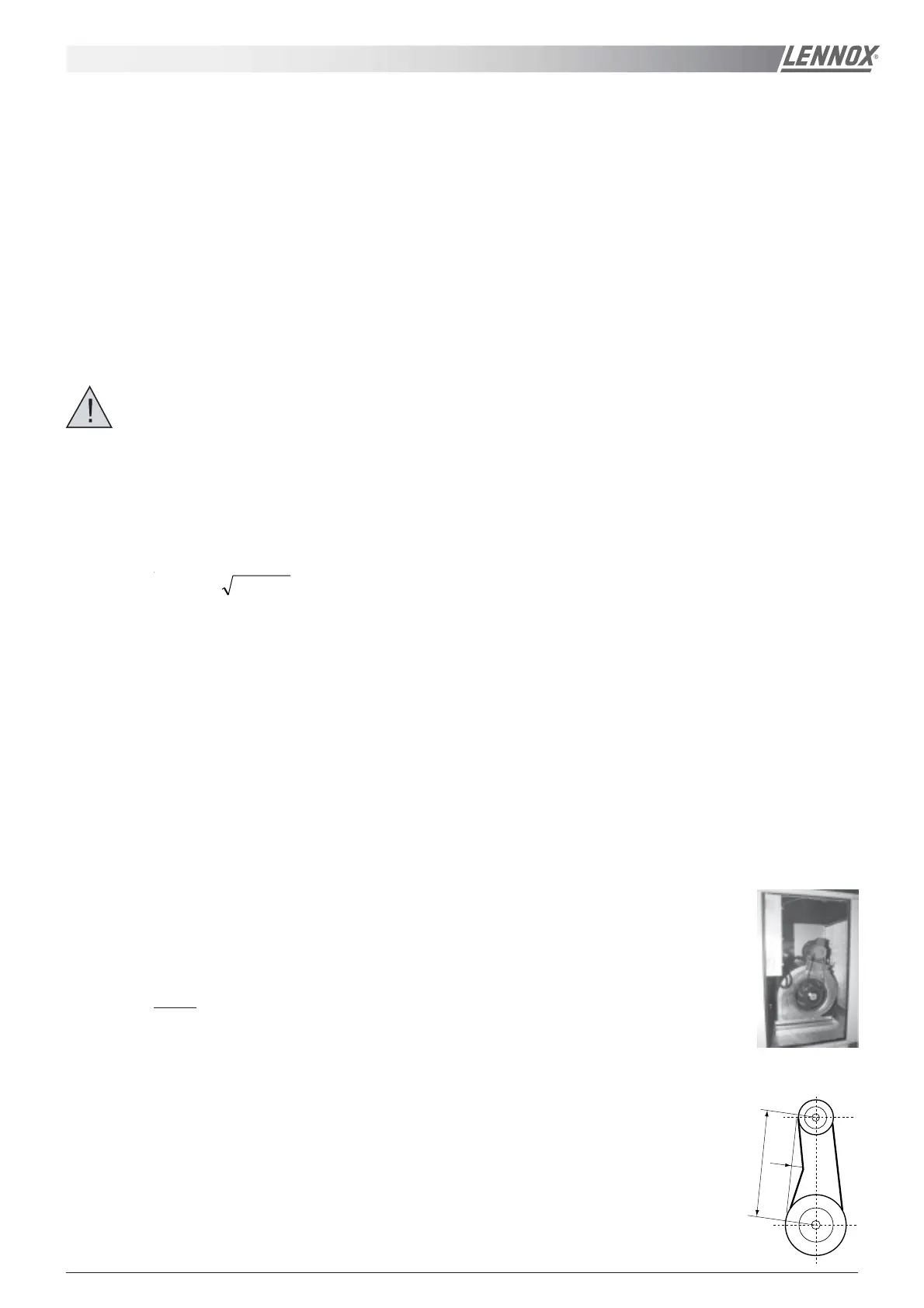

Check that according to the diagram below (figure 14), the following ratio remains the same.

A(mm)

≅

20

P(mm)

The belts should always be replaced when :

- the disk is set to maximum,

- the belt rubber is worn or the wire is visible.

Replacement belts must have the same rated size as the ones they are replacing. If a

transmission system has several belts, they must all be from the same manufacturing batch

(compare serial numbers).

PRELIMINARY CHECKS

Loading...

Loading...