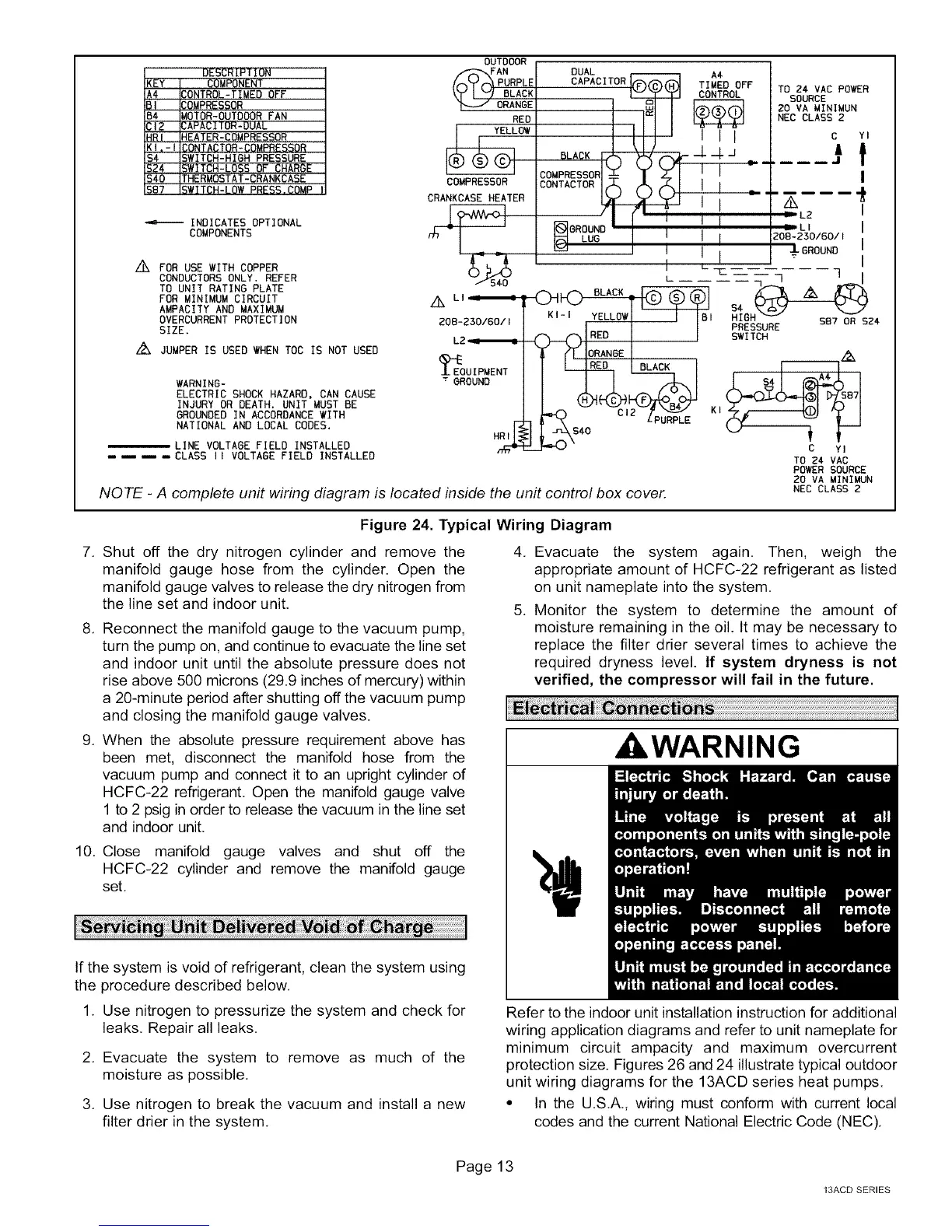

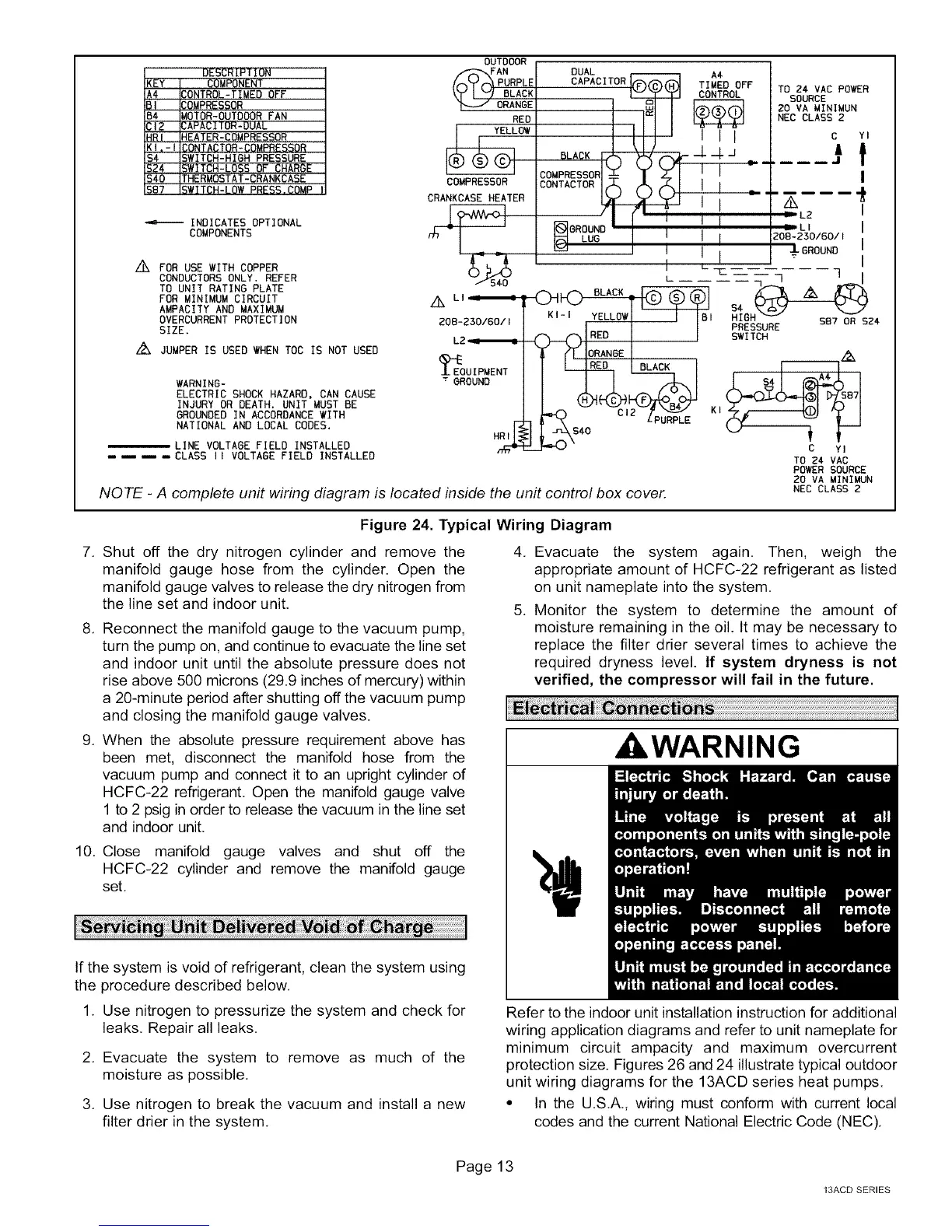

DESCRIPTION

MP N NT

A4 i]ONTROL-TIMED OFF

_I i]OMPRESSOR

54 i_OTOR-OUTDOOR FAN

_12 i]APACITOR-DUAL

HRI i4EATER-COMPRESSOR

KI.-liCONTACTOR-COMPRESSOR

$4 iSWlTCH-HIGH PRESSURE

587 i_WITCH-LOW PRESS.COMP I

INDICATES OPTIONAL

COMPONENTS

./_ FOR USE WITH COPPER

CONDUCTORS ONLY. REFER

TO UNIT RATING PLATE

FOR MINIMUM CIRCUIT

AMPACITY AND MAXIMUM

OVERCURRENT PROTECTION

SIZE,

Z_ JUMPER IS USED WHEN TOC IS NOT USED

WARNING-

ELECTRIC SHOCK HAZARD, CAN CAUSE

INJURY OR DEATH, UNIT MUST BE

GROUNDED IN ACCORDANCE WITH

NATIONAL AND LOCAL CODES.

_LINE VOLTAGE FIELD INSTALLED

I III CLASS II VOLTAGE FIELD INSTALLED

OUTDOOR

PURPLE

CLACK

ORANGE

RED

COMPRESSOR

CRANKCASE HEATER

DUAL

CAPACITOR

CONTACTOR

OROUND

LUG

208-23016011

L2.,_

_-_EOUIPMENT

= GROUND

A4

TIMED OFF

CONTROL

I I I

-L4_

I I

TO 24 VAC POWER

SOURCE

20 VA MINIMUN

NEC CLASS 2

HRI

r_

NOTE - A complete unit wiring diagram is located inside the unit control box cover.

KI-I YELLOWl I IBt HIBF 587 OR SZ4

o-oiRE°I i SW,TcHPRESSORE

$ (I ]ORANGEI .

C YI

TO 24 VAC

P_ER SOURCE

20 VA MINIMUN

NEC CLASS 2

Figure 24. Typical Wiring Diagram

7. Shut off the dry nitrogen cylinder and remove the

manifold gauge hose from the cylinder. Open the

manifold gauge valves to release the dry nitrogen from

the line set and indoor unit,

8. Reconnect the manifold gauge to the vacuum pump,

turn the pump on, and continue to evacuate the line set

and indoor unit until the absolute pressure does not

rise above 500 microns (29.9 inches of mercury) within

a 20-minute period after shutting off the vacuum pump

and closing the manifold gauge valves.

9. When the absolute pressure requirement above has

been met, disconnect the manifold hose from the

vacuum pump and connect it to an upright cylinder of

HCFC-22 refrigerant. Open the manifold gauge valve

1 to 2 psig in order to release the vacuum in the line set

and indoor unit,

10. Close manifold gauge valves and shut off the

HCFC-22 cylinder and remove the manifold gauge

set,

If the system is void of refrigerant, clean the system using

the procedure described below.

1. Use nitrogen to pressurize the system and check for

leaks, Repair all leaks,

2. Evacuate the system to remove as much of the

moisture as possible,

3. Use nitrogen to break the vacuum and install a new

filter drier in the system.

4. Evacuate the system again. Then, weigh the

appropriate amount of HCFC-22 refrigerant as listed

on unit nameplate into the system,

5. Monitor the system to determine the amount of

moisture remaining in the oil. It may be necessary to

replace the filter drier several times to achieve the

required dryness level. If system dryness is not

verified, the compressor will fail in the future.

I WARNING

Refer to the indoor unit installation instruction for additional

wiring application diagrams and refer to unit nameplate for

minimum circuit ampacity and maximum overcurrent

protection size. Figures 26 and 24 illustrate typical outdoor

unit wiring diagrams for the 13ACD series heat pumps.

• In the U.S,A., wiring must conform with current local

codes and the current National Electric Code (NEC),

Page 13

13ACD SERIES

Loading...

Loading...