Page 28 - IOM / ROOF-TOP FLEXY™ Series

GAS BURNERGAS BURNER

GAS BURNERGAS BURNER

GAS BURNER

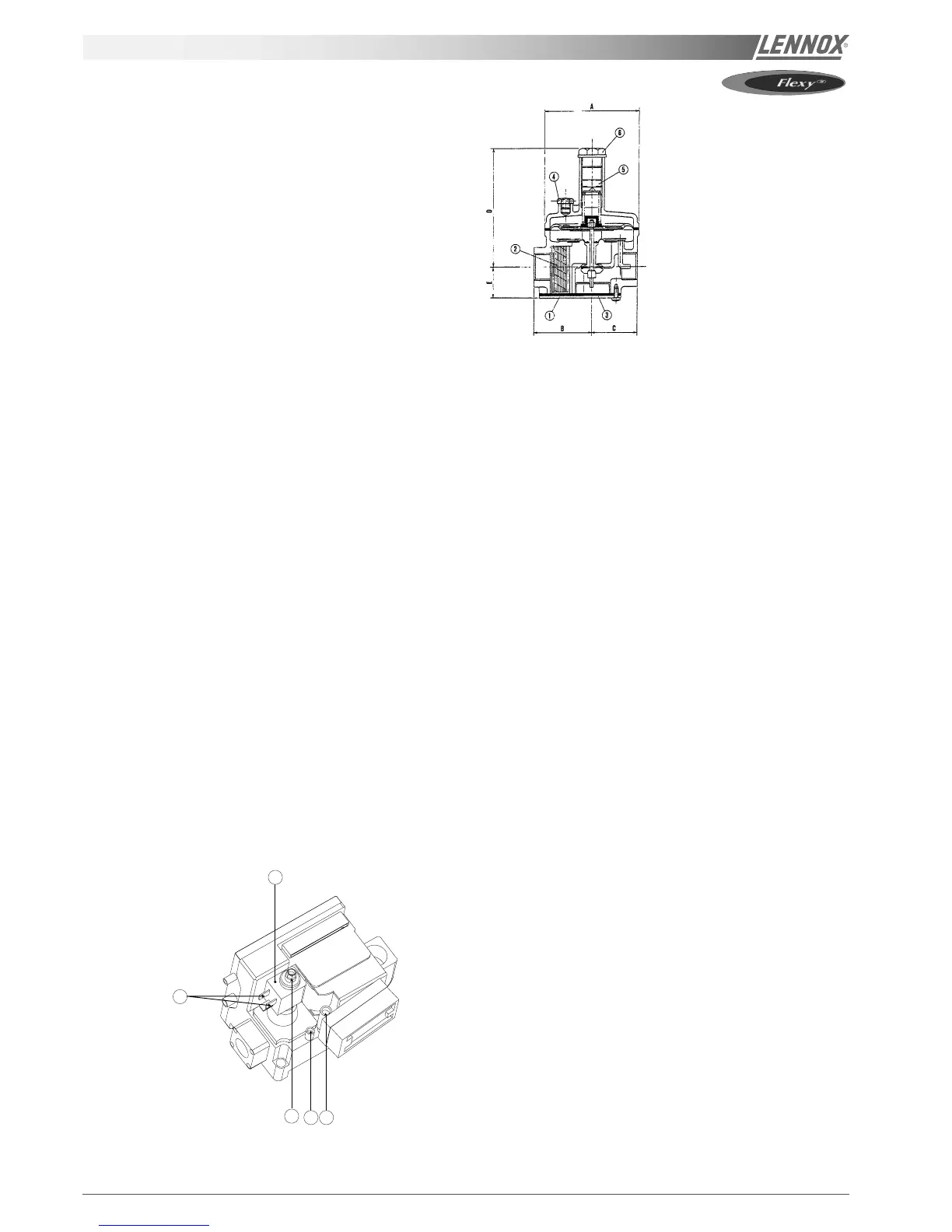

PRESSURE REDUCING VALVE SETTING

- Connect the tube of the manometer to the power

pressure inlet of a solenoid valve (5-figure 24) after

loosening the screw.

- Remove the safety plug of the expansion valve setting.

- Use a screwdriver to pre-set by placing the screw at a

depth of 34 mm.

- Place the burner(s) in operation at maximum power and

set the output pressure. Turn (clockwise) to increase the

pressure and (anticlockwise) to reduce it.

- When the pressure has been set, replace the safety

plug.

- Disconnect the pressure gauge and retighten the screw.

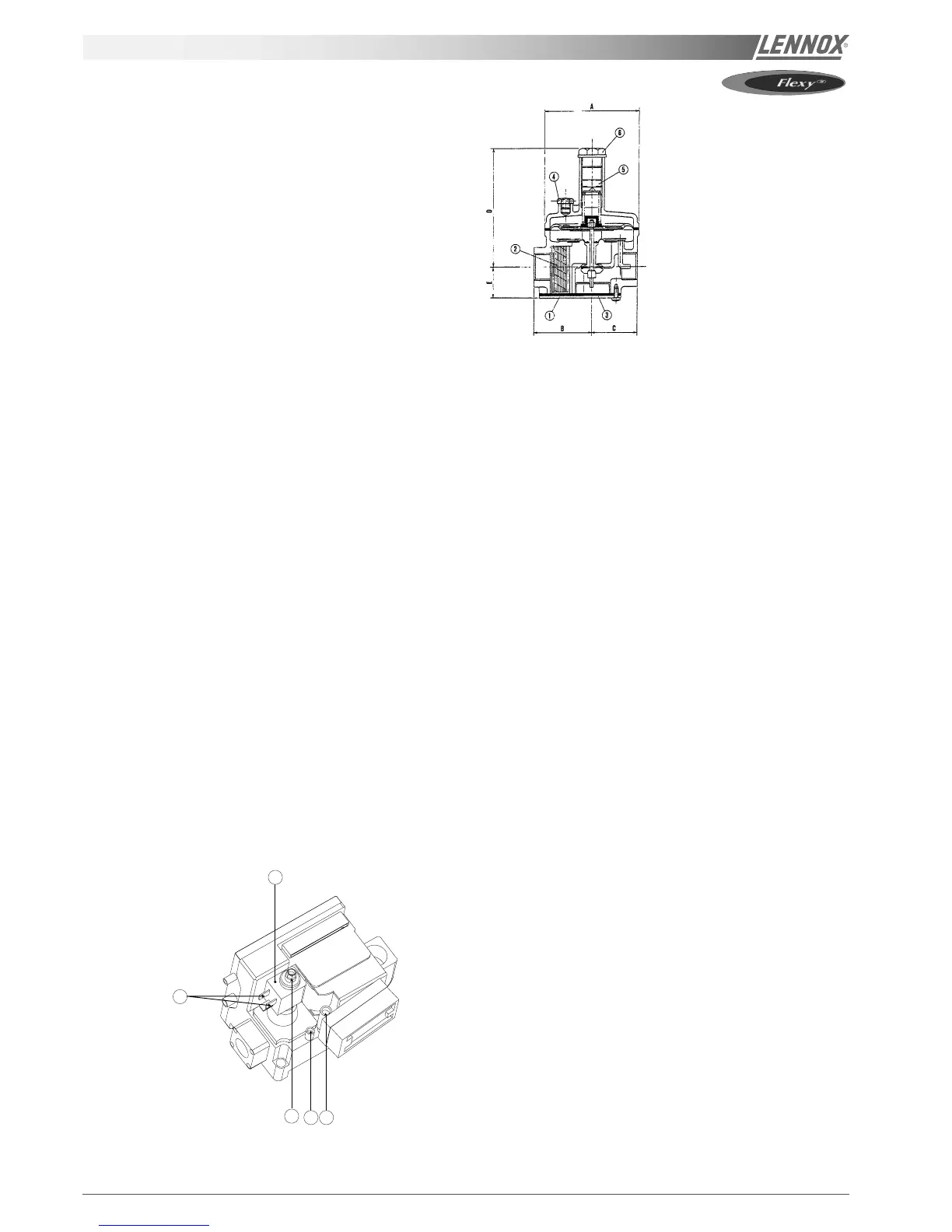

PRESSURE REGULATOR CONTROL OR

SETTING

This is located on the burner tiers (1 – figure 24) of the gas

control assembly.

- Increase the value of set point 1 (temperature set point)

to a temperature higher than room temperature )

(variable 1).

- Wait until the operation of the burner(s) reaches maxi-

mum power.

- Connect the tube of the manometer to the injection

pressure inlet after having loosened the screw (4-figure

24).

- Wait until a stable pressure is displayed on the pressure

gauge.

- Use a 8 mm key to adjust the maximum pressure (3 –

figure 24) – clockwise to increase it and anticlockwise to

reduce it. The maximum pressure must always be set

before setting the minimum pressure.

- The minimum pressure must be measured if the

regulator is not supplied. By disconnecting the tracer

wire 116 on card EF45 or EF46 for the one-ramp module

or the upper ramp of the two-ramp module. It can be

adjusted with a 3.5 mm screwdriver on the screw

located inside the maximum pressure setting.

- For the setting of the second ramp, disconnect the

tracer wire 116 or 126 in order to switch to low speed.

Figure 23

1

2

3

4 5

Pressure taps :

(4) : Injection

(5) : Supply

Figure 24

- Manipulate the regulator several times by connecting

and disconnecting wire 116 or 126 in order to check the

low and high speed settings.

Note : The maximum pressure setting affects the

minimum pressure setting and may have to be changed.

- When the settings are correct, connect wires 116 and

126, making sure they are properly tightened, remove

the pressure gauge and replace the safety cap.

- Restart the unit and watch the burner complete several

full cycles to ensure that all the components are working

properly.

NOTE : The minimum and maximum pressure settings

corresponding to the various gas types are listed in the table

at the end of this manual.

Loading...

Loading...