Page 44

Switches 14 through 19 -- Heating Mode Blower Speed

These switches are factory set at the OFF position which

provides 100 % of normal speed during HIGH HEAT de-

mand, 70% of normal speed during MID-RANGE HEAT

demand and 35% of normal speed during LOW HEAT

demand. Switches 14, 15 and 16 are used to adjust the

LOW HEAT blower motor speed. Switches 17, 18 and 19

are used to adjust the HIGH HEAT blower motor speed.

TABLE 22 provides the heating mode blower speeds that

will result from dierent switch settings. Refer to tables

beginning on page 42 for corresponding cfm values. See

TABLE 24 on page 48 for allowable heating speeds.

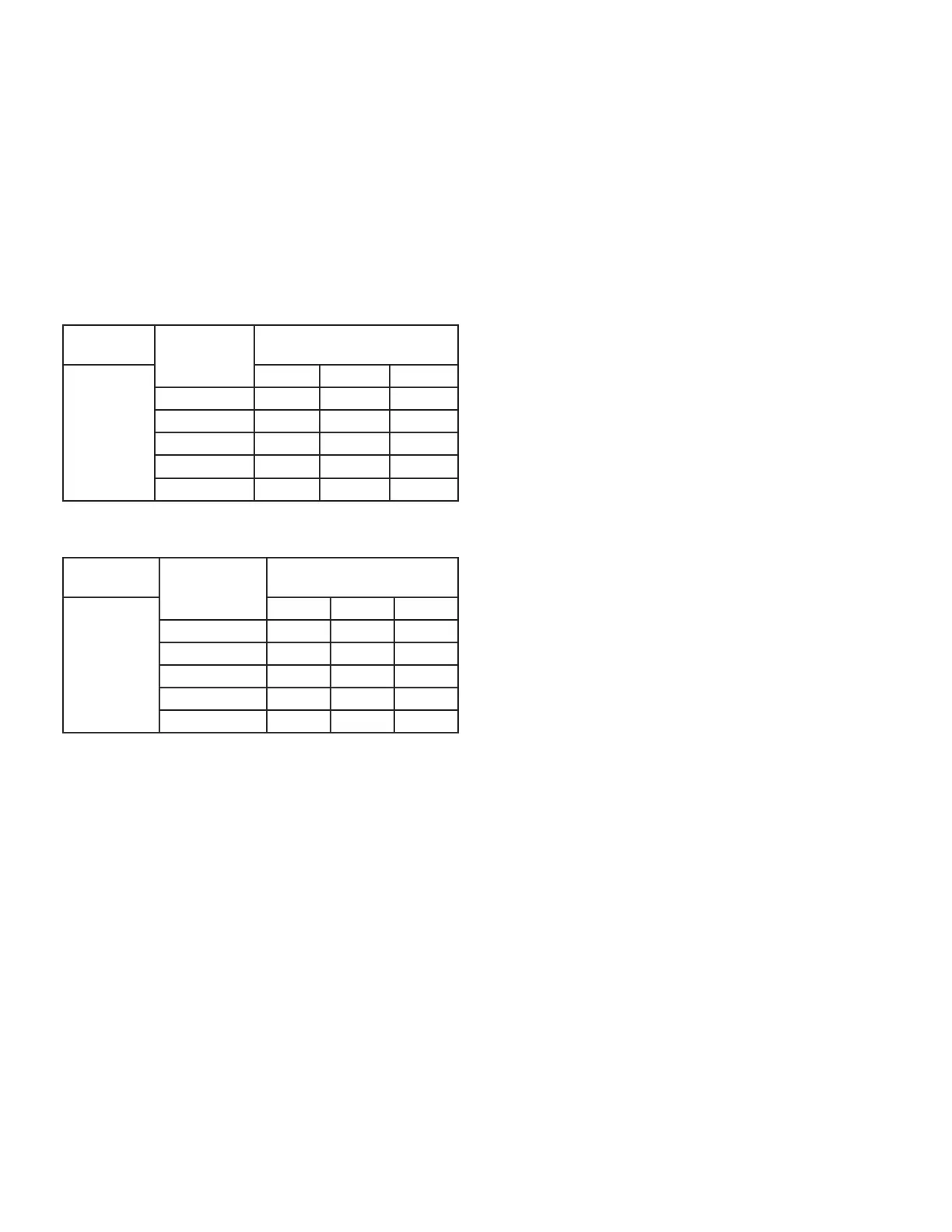

TABLE 22

Low Heat Blower Speeds

Thermostat

Demand

Blower

Speed

Adjustments

DIP Switch Settings

Low Heat

(R to W1)

14 15 16

+ 15% On O On

+ 7.5% On O O

Normal O O O

- 7.5% On On O

- 15% On On On

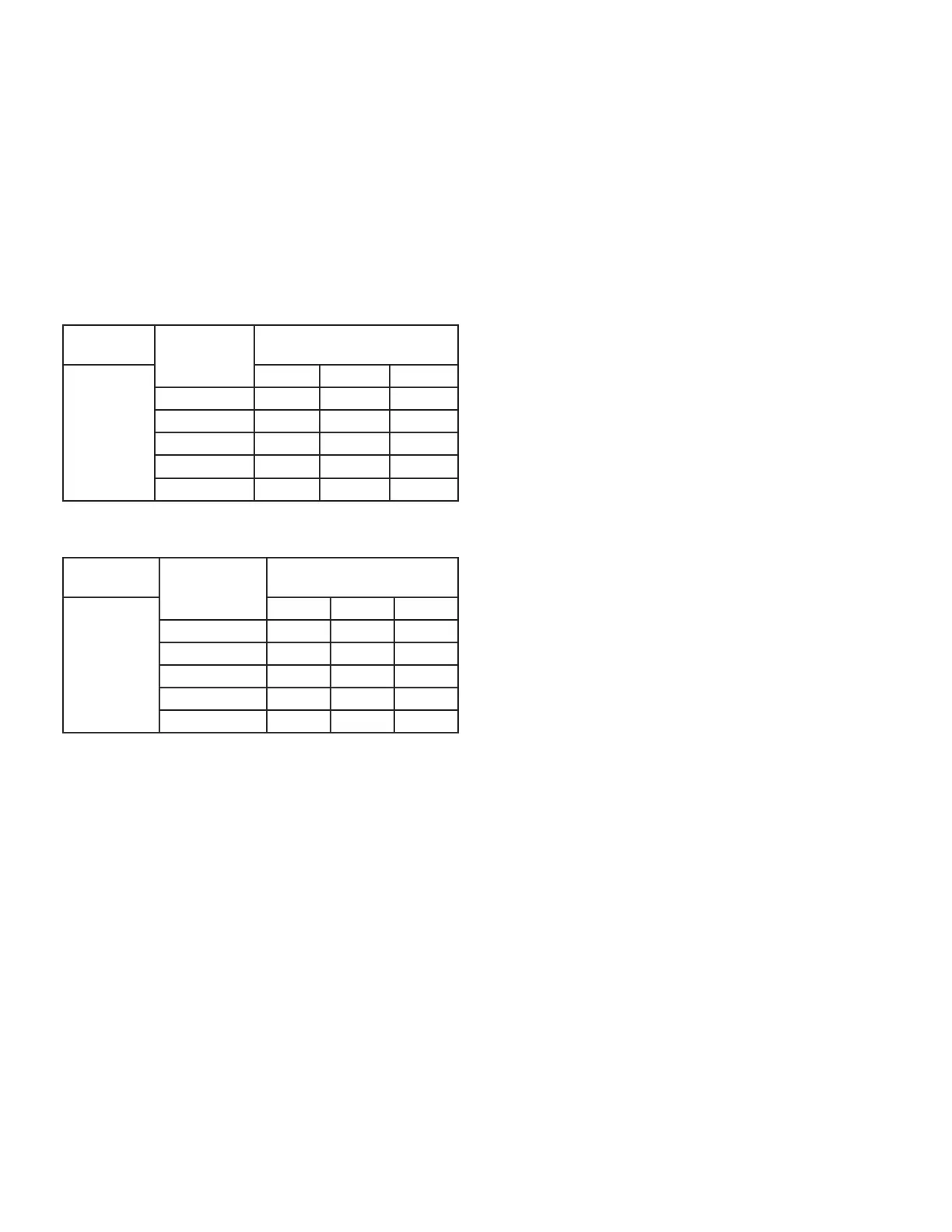

TABLE 23

High Heat Blower Speeds

Thermostat

Demand

Blower Speed

Adjustments

DIP Switch Settings

High Heat

(R to W1 &

W2)

17 18 19

+ 15% On O On

+ 7.5% On O O

Normal O O O

- 7.5% On On O

- 15% On On On

On-Board Links

On-Board links must be clipped (when applicable) before unit

is placed into operation with a non-communicating thermostat.

On-Board Link W914 DS to R (FIGURE 55)

On-board link W914, is a clippable connection between

terminals DS and R on the integrated control. W914 must

be cut when the furnace is installed with either the Harmo-

ny III zone control or a thermostat which features humidity

control. If the link is left intact the PMW signal from the

Harmony III control will be blocked and also lead to con-

trol damage. See TABLE 26 on page 48 for operation

sequence in applications including SLP99UHV, a thermo-

stat which features humidity control and a single-speed

outdoor unit. TABLE 27 gives the operation sequence in

applications with a two-speed outdoor unit.

On-Board Link W951 R to O (FIGURE 55)

On-board link W951 is a clippable connection between

terminals R and O on the integrated control. W951 must

be cut when the furnace is installed in applications which

include a heat pump unit and a thermostat which features

dual fuel use. If the link is left intact, terminal “O” will re-

main energized eliminating the HEAT MODE in the heat

pump.

On-Board Link W915 Y1 to Y2 (FIGURE 55)

On-board link W915 is a clippable connection between

terminals Y1 and Y2 on the integrated control. W915 must

be cut if two-stage cooling will be used. If the link is not cut

the outdoor unit will operate in second-stage cooling only.

Diagnostic LED (FIGURE 55)

The seven-segment diagnostic LED displays operating

status, target airow, error codes and other information.

The table beginning on Page 56 lists diagnostic LED

codes.

Diagnostic Push Button (FIGURE 55)

The diagnostic push button is located adjacent to the

seven-segment diagnostic LED. This button is used to

enable the Error Code Recall mode and the Field Test

mode. Press the button and hold it to cycle through a

menu of options. Every ve seconds a new menu item will

be displayed. When the button is released, the displayed

item will be selected. Once all items in the menu have

been displayed, the menu resumes from the beginning

until the button is released.

Error Code Recall Mode

Select ”E” from the menu to access the most recent 10

error codes. Select “c” from the Error Code Recall menu

to clear all error codes. Button must be pressed a second

time while “c” is ashing to conrm command to delete

codes. Press the button until a solid “≡” is displayed to exit

the Error Code Recall mode.

Field Test Mode

Use the diagnostic push button to scroll through the menu

as described above. Release the button when the LED

ashes “-” to select the Field Test mode.

While in the Field Test mode the technician can:

• Initiate furnace ignition and move to and hold low-re

rate by applying a R to W1 jumper.

• Initiate furnace ignition sequence and move to and hold

high-re rate by applying a jumper from R to W1 and

W2.

• Initiate furnace ignition sequence and move to and hold

mid-re rate by applying a jumper to R and W2.

• Apply then remove the jumper from R to W1 and W2 to

change the ring rate from low re to mid re and high

re.

• A vent calibration sequence can be initiated even if a

thermostat signal is not present. Press and hold the

push button until a solid “C” is displayed. Release the

button and calibration will begin. The furnace will per-

form the high-re and low-re pressure switch calibra-

tions and display “CAL”. After calibration, the LED will

return to the ashing “-” display.

During Field Test mode operation, all safety switches are

still in the circuit (they are not by-passed) and indoor blow-

er performance and timings will match DIP switch selec-

tions. Current furnace ring rate, indoor blower CFM and

ame signal will be displayed. To exit the Field Test mode,

press and hold the button. The menu will resume from the

beginning. Also, cycle the main power to exit the Field Test

mode. The integrated control will automatically exit the

Field Test mode after 45 minutes of operation.

Loading...

Loading...