Page 20

D-Determining Unit CFM

NOTE - Units equipped a Variable Frequency Drive (VFD)

are designed to operate on balanced, three-phase power.

Operating units on unbalanced three-phase power will re-

duce the reliability of all electrical components in the unit.

Unbalanced power is a result of the power delivery system

supplied by the local utility company. Factory-installed in-

verters are sized to drive blower motors with an equiva-

lent current rating using balanced three-phase power. If

unbalanced three-phase power is supplied; the installer

must replace the existing factory-installed inverter with an

inverter that has a higher current rating to allow for the im-

balance. Refer to the installation instructions for additional

information and available replacements.

1 - The following measurements must be made with a

Units Equipped With An Inverter -

Initiate high speed blower without a cooling demand.

2 -

3 -

Blower performance data is based on static pressure

Note - Static pressure readings can vary if not taken

where shown.

4 -

pages 16 and 17 when installing units with any of

the optional accessories listed.

Loosen Allen screw and turn adjustable pulley

minimum and maximum number of pulley turns as

shown in table 1.

6 - Units Equipped With An Inverter -

pressure switches S4 and S7.

TABLE 1

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt Min Turns Open Max Turns Open

A Section 0

B Section 1* 6

*No minimum number of turns open when B belt is used

on pulleys 6” O.D. or larger.

E-Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are maintained.

Tension new belts after a 24-48 hour period of opera-

tion. This will allow belt to stretch and seat in the pulley

grooves. Make sure blower and motor pulleys are aligned

1 - Loosen four bolts securing motor base to mounting

2 - To increase belt tension -

move the motor outward and tighten the belt. This in-

creases the distance between the blower motor and

the blower housing.

To loosen belt tension -

to loosen belt tension.

IMPORTANT - Align top edges of blower motor base

and mounting frame base parallel before tightening

two bolts on the other side of base. Motor shaft and

blower shaft must be parallel.

3 - Tighten two bolts on each side of the motor mounting

base. This secures the mounting base to the frame

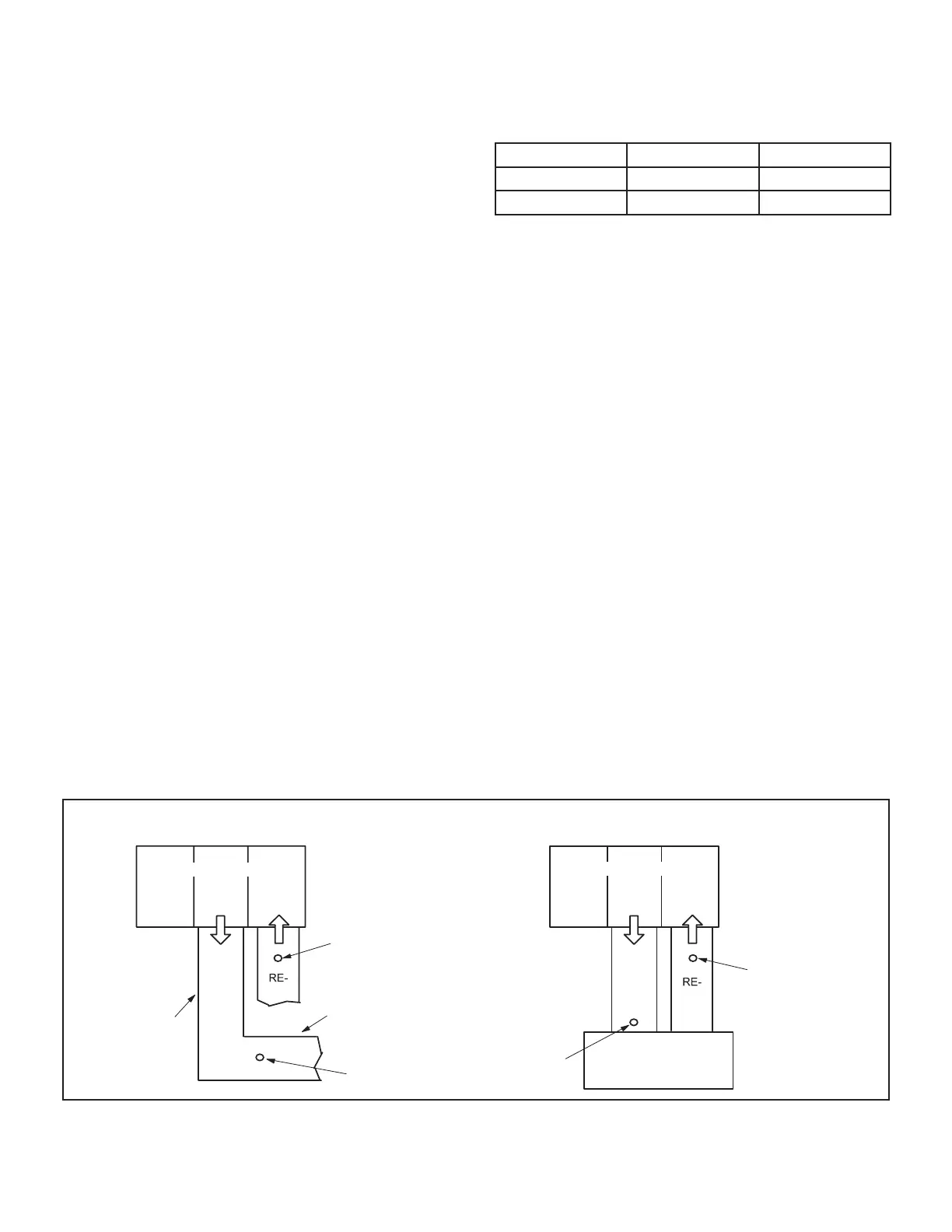

LOCATION OF STATIC PRESSURE READINGS

SUPPLY AIR

READING

LOCATION

SUPPLY

TURN

INSTALLATIONS WITH DUCTWORK

SUPPLY

TURN

INSTALLATIONS WITH CEILING DIFFUSERS

MAIN

DUCT RUN

FIRST BRANCH

OFF OF MAIN RUN

DIFFUSER

ROOFTOP UNIT

ROOFTOP UNIT

SUPPLY AIR

READING

LOCATION

RETURN AIR

READING LOCATION

RETURN AIR

READING

LOCATION

FIGURE 6

Loading...

Loading...