Operating mode

Vector control

10

Function library

10.3

10.3.2

L

10.3-10

EDS82EV903-1.0-11/2002

In general, the vector control is ready for operation after the motor parameters

have been identified. Vectorcontrol must only be optimised forthe following drive

performance: 43

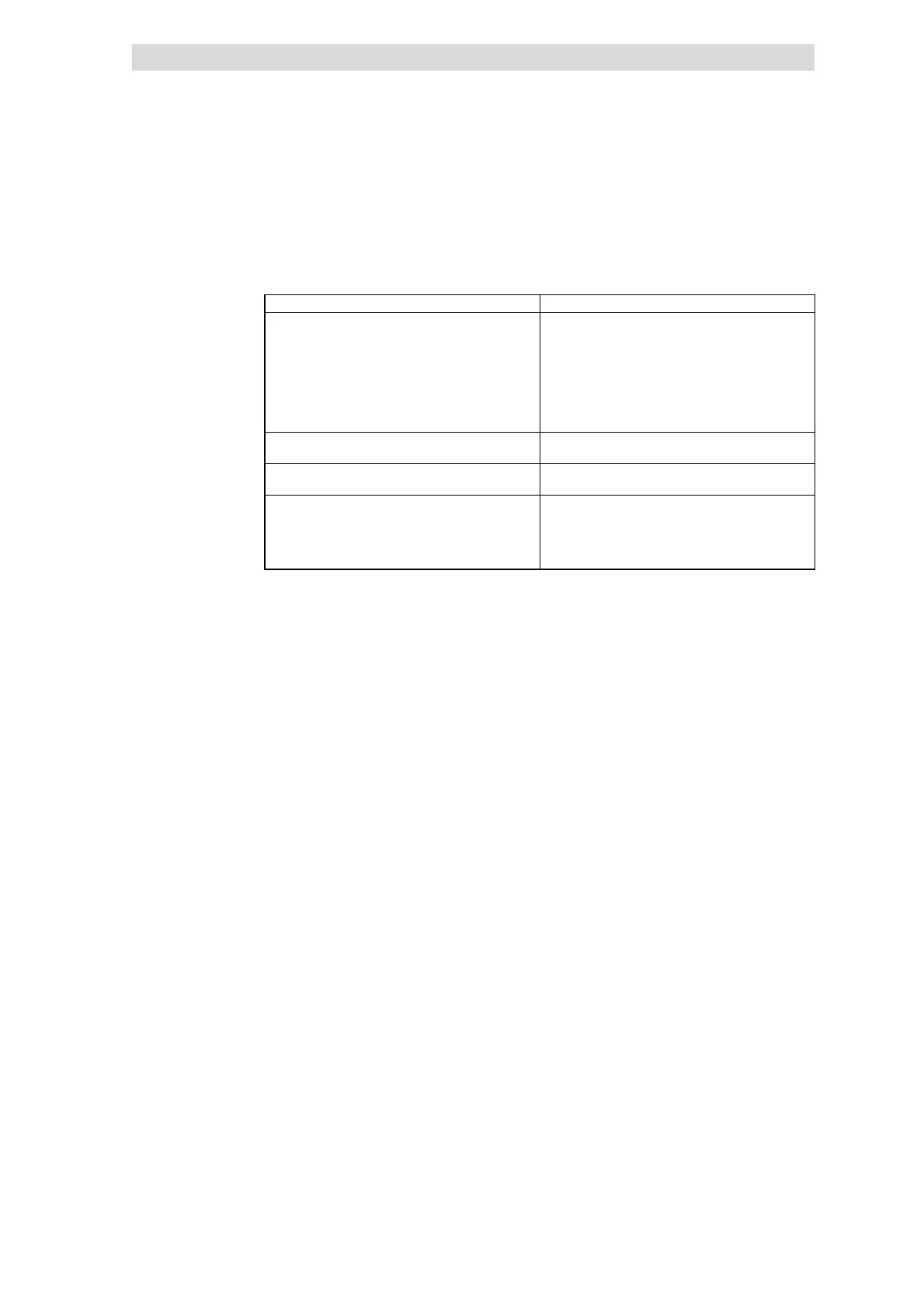

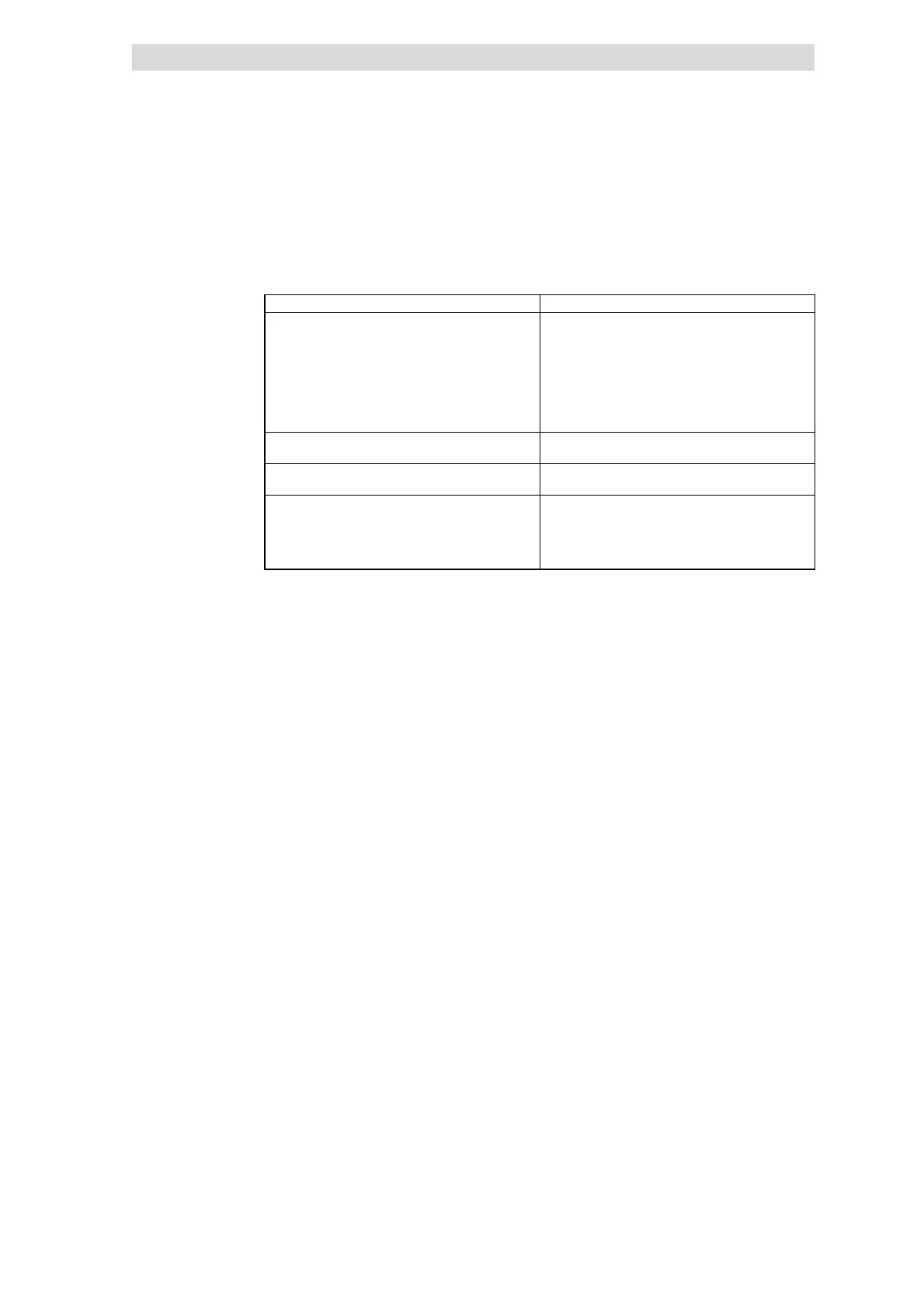

Drive performance Remedy

Rough motor run and motor current (C0054) > 60 %

rated motor current in idle running (stationary operation)

1. Reduction of motor inductance (C0092) by 10 %

2. Check of motor current under C0054

3. If the motor current (C0054) > 50 % of the rated

motor current:

– C0092 must be reduced until the mot or current

amounts to 50 % of the rated motor current

– Reduce C0092 by max. 20 %!

– Note: If you reduce C0092 the t o rque will decrease!

Torque too low for frequencies f < 5 Hz (starting torque) Increase of motor resistance (C0084) or increase of

motor inductance (C0092)

Poor constant speed at high loads (setpoint and motor

speed are not proportional).

Increase o f slip compensa t i on (C0021)

Overcompensation results in drive instability!

Error messages OC1, OC3, OC4 or OC5 during

acceleration times (C0012) < 1 s (drive controller is no

longer able to follow the dynamic processes)

Change readjustment time of the I

max

controller (C0078):

• Reduction o f C0078 = I

max

controller becomes quicker

(more dynamic)

• Increase of C0078 = I

max

controller becomes slower

(”smoother”)

Optimising the vector control

Loading...

Loading...