Lewmar V1-6 & SPORT Windlass | 20

5.3 Hose types

For reliable operation and safety it is

essential to use reinforced braid hose

for connecting to the motor A and B

ports which conforms to SAE100R2A or

DIN 20 021 Part 2.

The recommended hose sizes are:

• Up to 30 l/min +

1

/

2

” (13 mm) bore

diameter.

• Up to 40 l/min +

5

/

8

” (16 mm) bore

diameter.

• Up to 57 l/min +

3

/

4

” (19 mm) bore

diameter.

• Ref: 3.78 litres = 1 US gallon

4.54 litres = 1 Imperial gallon

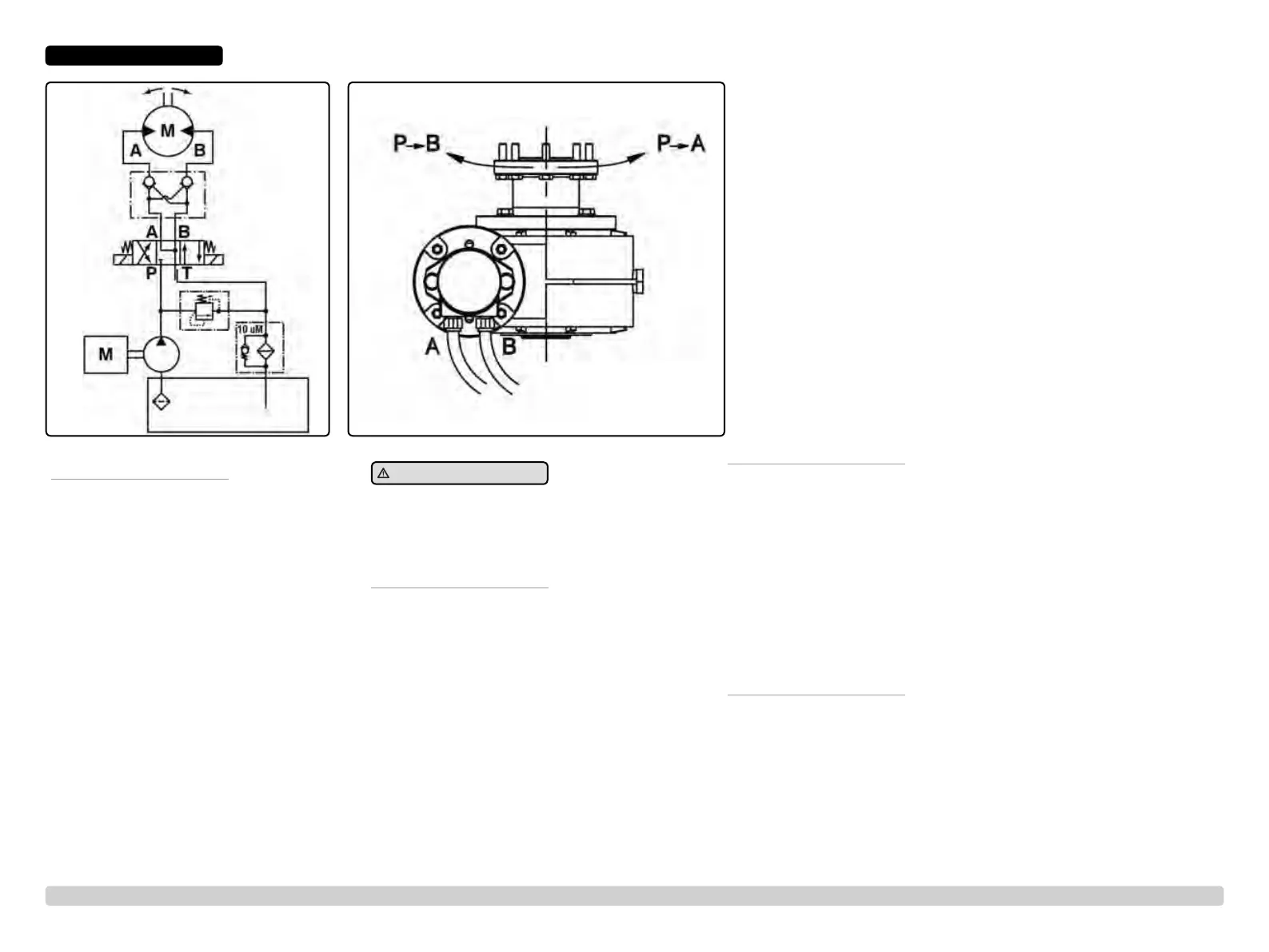

5.4 Motor ports - standard

motor/gearbox

The location of the ports for the

standard motor/gearbox is shown in

Fig 5.4-1 (no drain connection).

• The Lewmar hydraulic motor ports

are: A & B ports ½” BSP.

• NOTE: Refer to your installed

hydraulic system manual for

hydraulic drives.

5. Hydraulic System

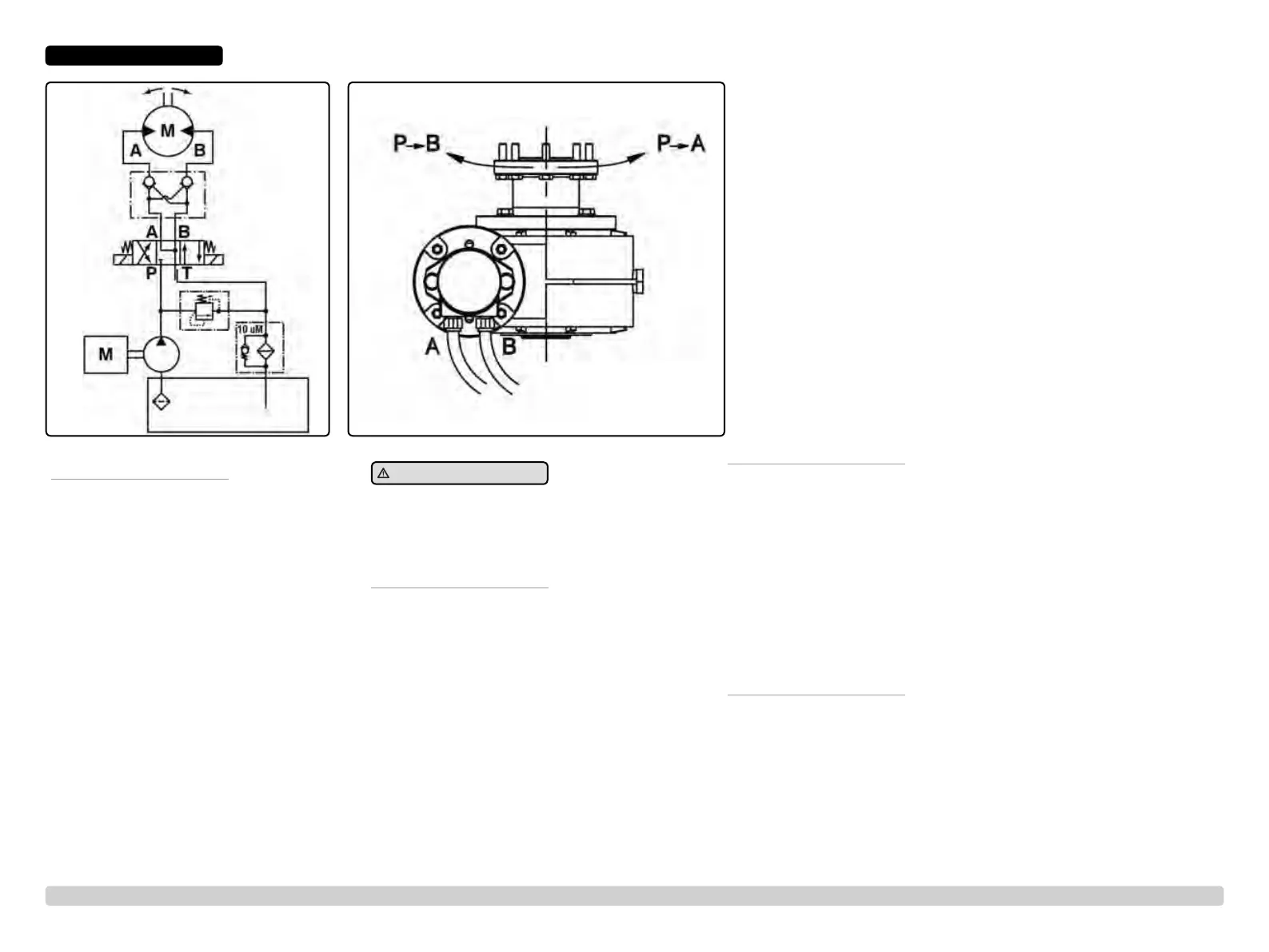

Fig 5.1-1

Standard Motor/gearbox Fig 5.4-1

5.1 Installation

• NOTE: Hydraulic system installation

is NOT covered in this publication.

Lewmar hydraulic windlasses have

been designed for ease of installation

and follow a straightforward hydraulic

and mechanical installation procedure.

Windlass unit should be connected to

a hydraulic powerpack with directional

control valve installed to control the

windlass movement.

Fig 5.1-1 shows a typical hydraulic

circuit for a V6 windlass.

The purpose of this manual is to

provide the reader with suffi cient

information to install and operate

a hydraulic windlass. It assumes

the reader will be familiar with

sailing craft, marine hydraulics and

mechanical installation and safety

requirements. If in any doubt consult a

qualifi ed marine engineer.

• The installation of hydraulic systems

requires a high level of cleanliness.

The ingress of dirt will dangerously

impair the safe operation of the

system and cause premature wear of

hydraulic components.

5.2 Hydraulic motor/gearbox

The hydraulic motor/gearbox consists

of a high torque hydraulic motor fi tted

to a 7:1 90 degree gearbox.

The hydraulic motors have a maximum

pressure rating of 180 bar and can be

used with an oil supply of up to 57 l/min.

The motor gearboxes are not self

sustaining. A dual Pilot Operated

Check Valve (POCV) must be installed

in the system to temporarily sustain

any load. The POCV can be line

mounted (as shown in Fig 5.1-1) or

modular type if for example a CETOP 3

directional valve is being used.

• NOTE: To permanently sustain a load

a Chain Stopper must be used.

WARNING!

Loading...

Loading...