Maintenance

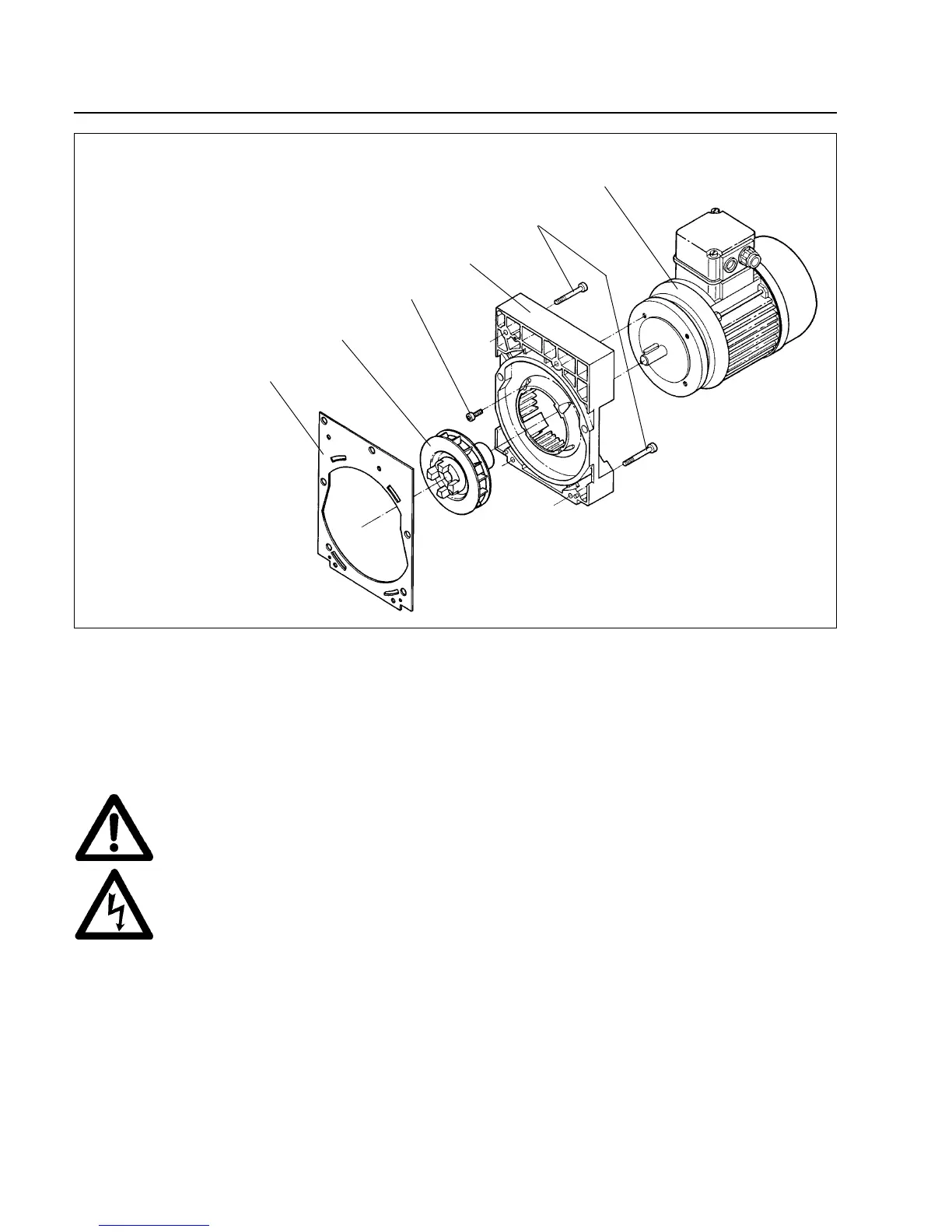

3.5 Disassembly and

Reassembly of the

Electric Motor

Before starting any disassembly work,

always disconnect the motor from the

mains.

Reliably prevent the pump from running up.

Required tools:

Screwdriver 1.0 x 5.5 mm (for junction box), open-jaw

wrenches size 7 and size 19 (for junction box), Allan keys

size 3 and size 6.

Possibly a puller for the coupling.

Disconnect the mains connection.

Support the motor.

Unscrew the four non-recessed hex. socket screws

(11/5).

Remove the intermediate flange (11/4) together with the

electric motor.

Remove the gasket (11/1).

Loosen the threaded pin and pull the coupling with the

blade wheel (11/2) off the motor shaft.

Unscrew the hex. socket screws (11/3).

Remove the electric motor (11/6).

Clean all parts and check that they are in perfect

condition; if not, replace them with new parts.

Reassemble in the reverse order.

In the case of 60 Hz motors (USA versions)

the coupling must not be pushed on to the

shaft right up to the stop. On the other hand

if it is not pushed on far enough the pump

module may be damaged during operation.

Push the coupling on in such a way that the

distance between the front end of the

coupling and the gasket (11/1) on the

intermediate flange amounts to 43.7 mm.

18

Fig. 11 Disassembly and reassembly of the electric motor

Key to Fig. 11

1 Gasket

2 Coupling with fan blades

3 Hex. socket screws

4 Intermediate flange

5 Hex. socket screws

6 Electric motor

Caution

Warning

1

2

3

4

5

6

Loading...

Loading...