24 300598802_002_C0 - 10/2016 - © Leybold

Maintenance

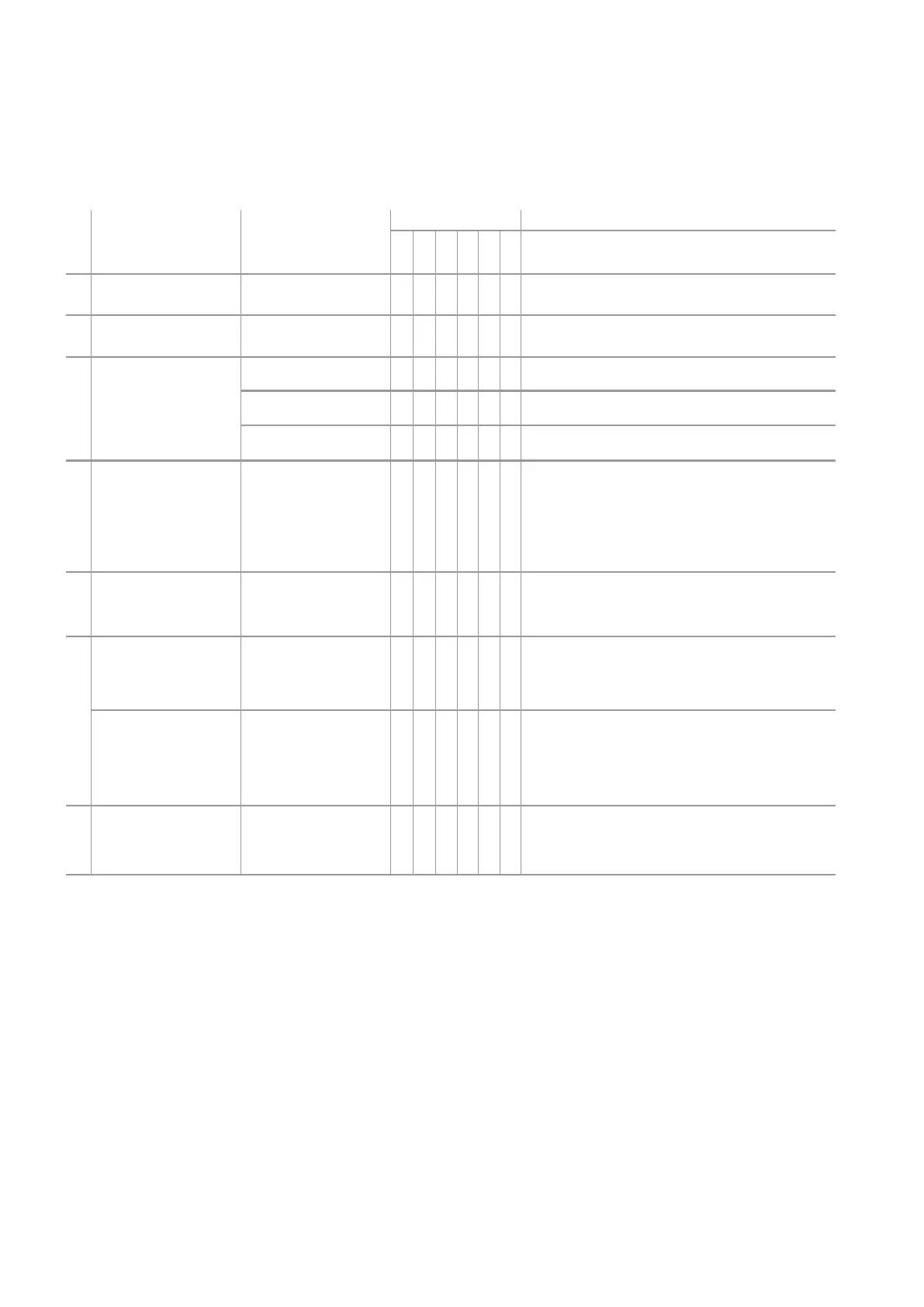

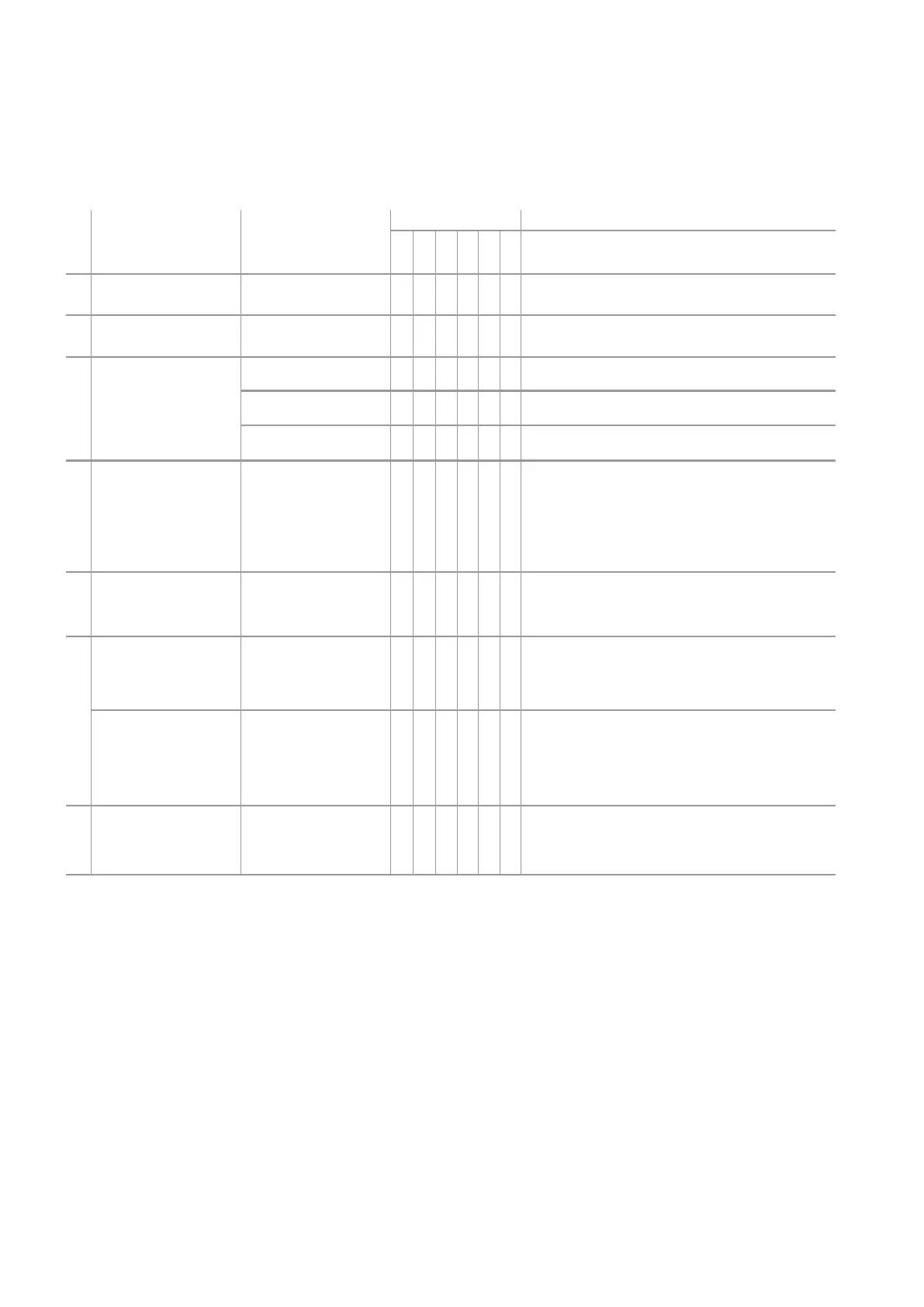

5.1 Maintenance Plan

No.

Rotary vane pumps

Trivac D4T

Trivac D8T

Trivac D16T

Trivac D30T

Measurement / test quantity

Operating / auxiliary materi-

als

Interval Remarks

VE VP t 6m a n-a

Refer also to the Operating Instructions - Section: individual

components.

1

Operate the pump for at

least 1 hours with gas bal-

last.

×

Condensed water is thus removed from the oil.

2

Check the oil level, change

the oil if required.

Oil: LVO100 or special and

alternative oils, see Chapter

1.2

× ×

Refill: only after the pump has been switched off.

3

Check the quality of the oil,

change the oil if required.

visually (all oils)

× ×

Visually: normally light and transparent, oil change is required

when discolorations increase.

chemically

×

Chemically: to DIN 51558 when the neutralization number

exceeds 2; then an oil change will be required.

mechanically

×

Mechanically: when dynamic viscosity at 25 °C exceeds 300

mPas; then an oil change will be required.

4

Clean the dirt trap in the

intake port, change it as

required.

Suitable cleaning agent and

compressed air

×

■Clean dirt trap with a cleaning agent and blow it out with

compressed air under a suction hood.

■Replace the defective dirt trap.

Use a cleaning agent which complies with the national / inter-

national specifications.

Observe the safety regulations when using cleaning

agents

5

Check the edges of the teeth

on the coupling element for

any damages, change the

coupling element as re-

quired.

×

6

Change the oil -

and

Oil:

LVO100

×

Oil change:

■ First oil change after 100 operating hours

■ Pump switched off and cold.

Change the oil when the pump is cold in order to avoid releas-

ing absorbed gases.

clean the oil level glass. Suitable cleaning agent and

compressed air.

Clean the oil level glass with a cleaning agent and blow it out

with compressed air under a suction hood.

Cleaning agent according to national / international specifica-

tions.

Observe the safety regulations when using cleaning

agents.

Quantity of oil: see Operating Instructions, Section 1.6.

7

Check the fan of the pump

and the motor as well as

the cooling fins on the

motor for deposits and

clean as required.

Brush and industrial vacuum

cleaner.

×

Already clean before the maintenance interval has elapsed

when the pump or the motor gets to warm.

Caution: switch off the pump and ensure that it can not run up

inadvertently (disconnect from the mains).

We recommend that you service the pump every two years concerning the following:

■ Cleaning

■ Checking of the individual components

■ Exchange of all seals

■ Function check

This check should be run by the Leybold service.

Key to the maintenance plan

VE = Maintenance before switching on the system

VP = Maintenance before starting production

t = Daily maintenance

6m = Six monthly maintenance

a = Annual maintenance

n-a = Maintenance every n years

Loading...

Loading...