- 9 -

LGE Internal Use Only

Copyright © LG Electronics. Inc. All right reserved.

Only for training and service purposes

4. Final Assembly Adjustment

4.1. White Balance Adjustment

4.1.1. Overview

▪ W/B adj. Objective & How-it-works

(1) Objective: To reduce each Panel's W/B deviation

(2) How-it-works : When R/G/B gain in the OSD is at 192, it

means the panel is at its Full Dynamic Range. In order to

prevent saturation of Full Dynamic range and data, one of

R/G/B is xed at 192, and the other two is lowered to nd

the desired value.

(3) Adjustment condition : normal temperature

1) Surrounding Temperature : 25 °C ± 5 °C

2) Warm-up time: About 5 Min

3) Surrounding Humidity : 20 % ~ 80 %

4) Before White balance adjustment, Keep power on

status, don’t power off

* Adj. condition and cautionary items

(1) Lighting condition in surrounding area surrounding lighting

should be lower 10 lux. Try to isolate adj. area into dark

surrounding.

(2) Probe location: Color Analyzer (CA-210) probe should

be within 10cm and perpendicular of the module surface

(80°~ 100°)

(3) Aging time

1) After Aging Start, Keep the Power ON status during

5 Minutes.

2) In case of LCD, Back-light on should be checked

using no signal or Full-white pattern.

4.1.2. Equipment

(1) Color Analyzer: CA-210 (NCG: CH 9 / WCG: CH12 / LED:

CH14)

(2) Adj. Computer (During auto adj., RS-232C protocol is

needed)

(3) Adjust Remocon

(4) Video Signal Generator MSPG-925F 720p/204-

Gray(Model: 217, Pattern: 49)

* Color Analyzer Matrix should be calibrated using CS-1000

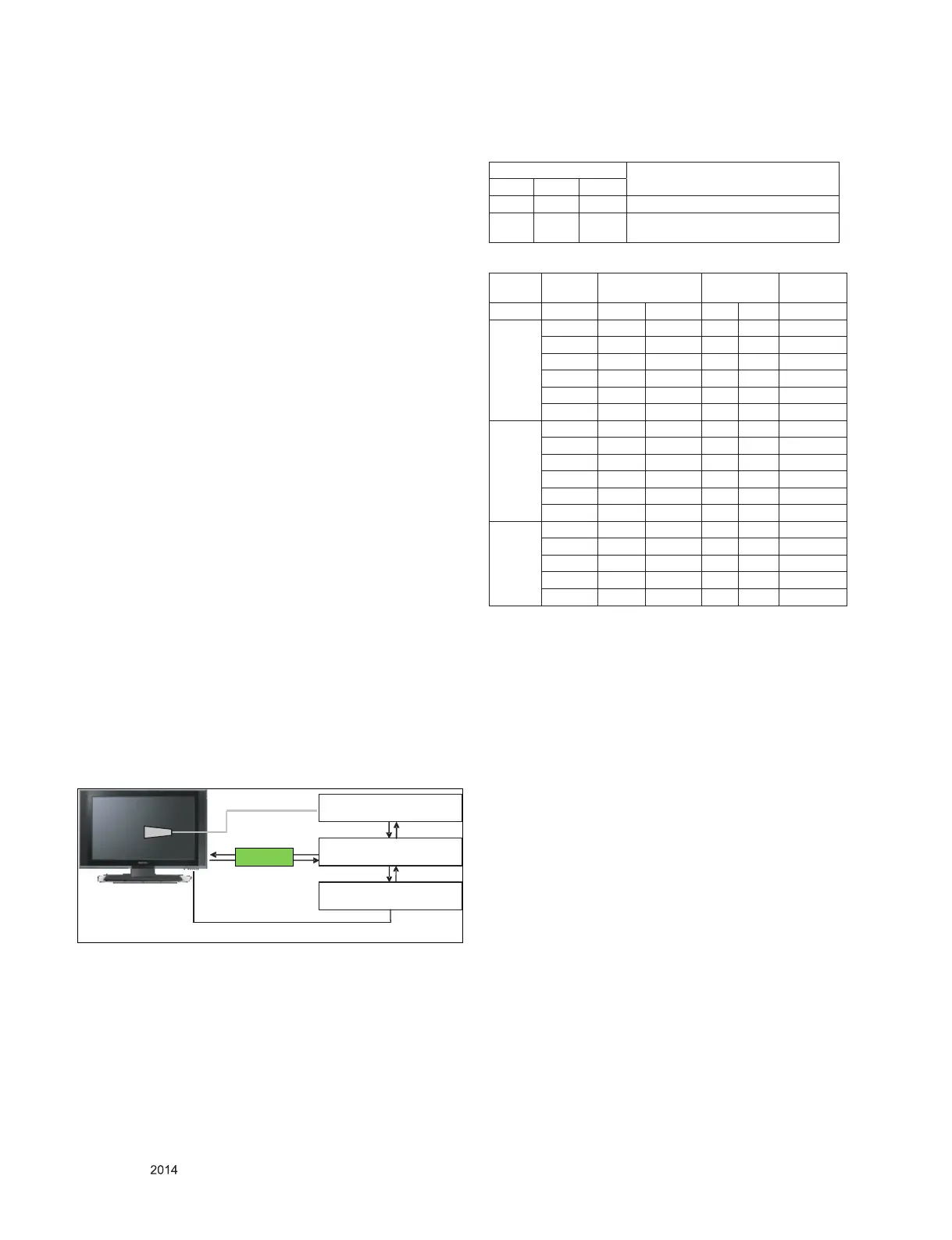

4.1.3. Equipment connection

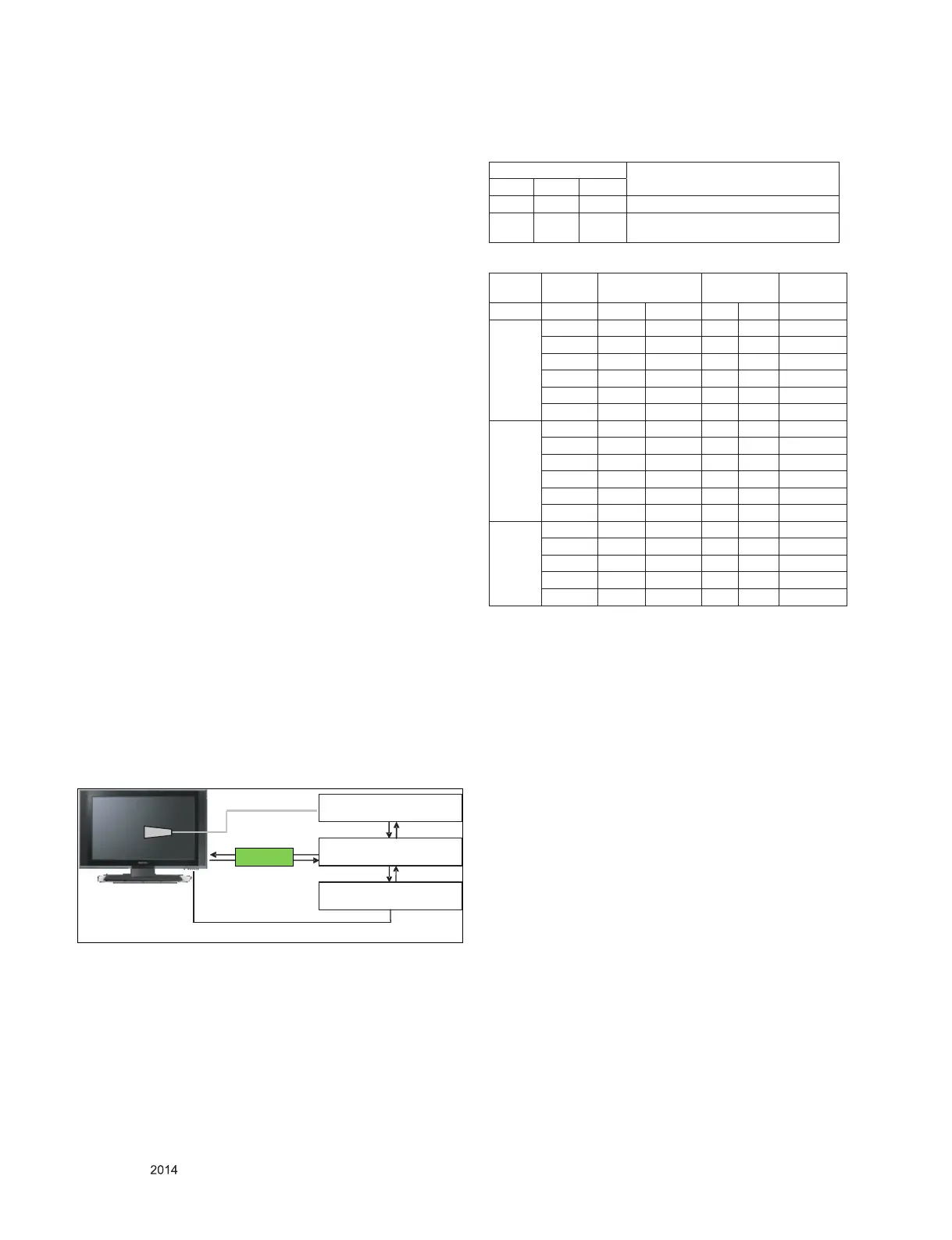

4.1.4. Adjustment Command (Protocol)

(1) RS-232C Command used during auto-adj.

(2) Adjustment Map

RS-232C COMMAND

Explantion

CMD ID DATA

wb 00 00 Begin White Balance adjustment

wb 00 ff

End White Balance adjustment

(internal pattern disappears )

Adj. item

Command

(lower caseASCII)

Data Range

(Hex.)

Default

(Decimal)

CMD1 CMD2 MIN MAX

Cool

R Gain j g 00 C0

G Gain j h 00 C0

B Gain j i 00 C0

R Cut

G Cut

B Cut

Medium

R Gain j a 00 C0

G Gain j b 00 C0

B Gain j c 00 C0

R Cut

G Cut

B Cut

Warm

R Gain j d 00 C0

G Gain j e 00 C0

B Gain j f 00 C0

R Cut

G Cut

Co lo r Analyzer

Co m pu ter

Pattern Generator

RRGB Cable S-2 32C

RS-232C

RS-232C

Probe

Signal Source

* If TV internal pattern is used, not needed

DFT JIG

Loading...

Loading...