HSLG Slide Gate Operator Installation Guide - 3 - P1220 Revision X8 6-22-2011

Mounting Pad Installation

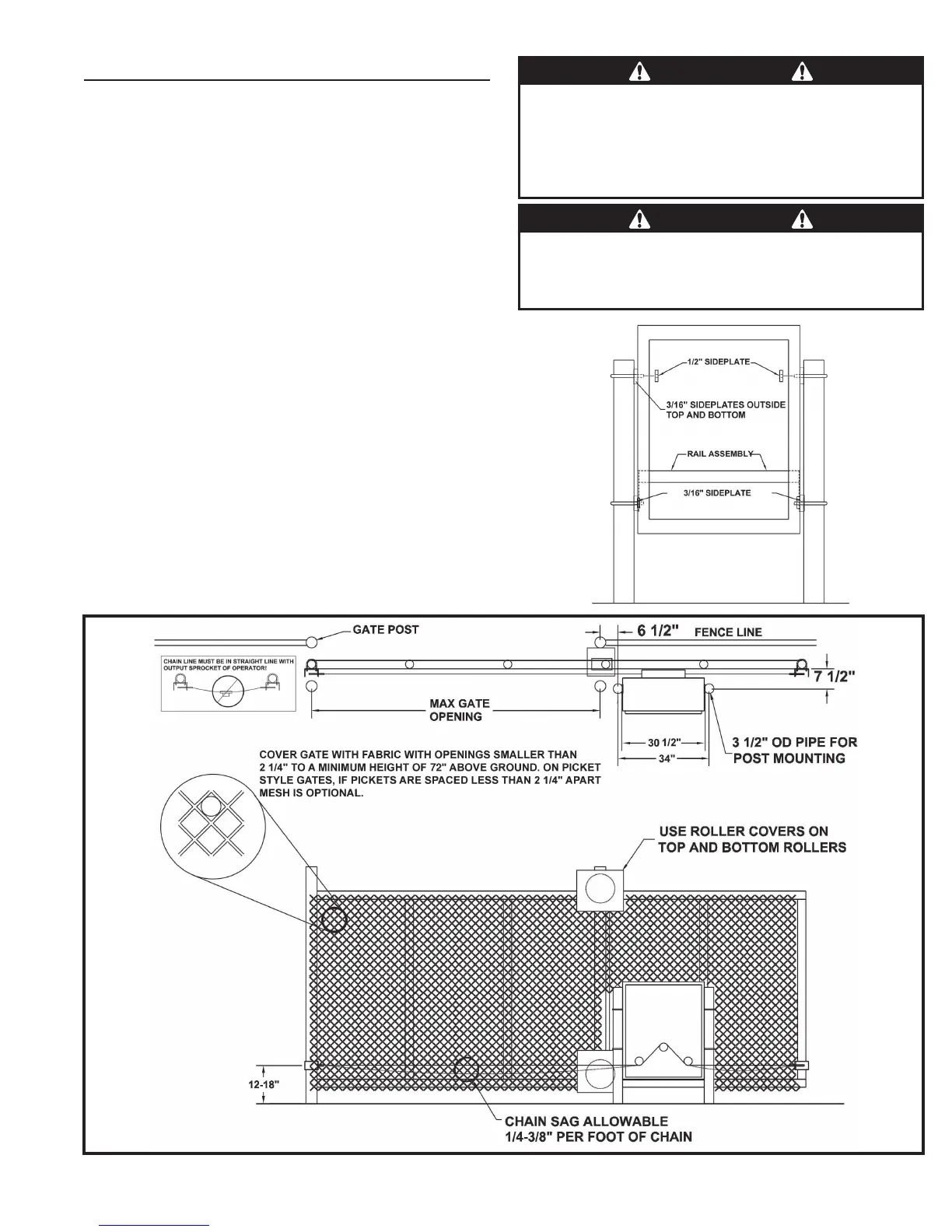

The gate operator mounts bolted to posts secured in

concrete footings. The posts support the operator and

prevent it from moving during operation. For optional pad

mounting instructions, see Linear drawing #2700-360.

Gate Preparation

Before installing, make sure the gate rolls or slides freely,

and that all exposed rollers are properly covered. The gate

must be covered with fabric with openings no larger than

2-1/4” in size, to a minimum height of 72” above ground

level. On picket-style gates, if pickets are spaced less than

2-1/4” apart, mesh is optional.

Mounting Specifi cations

Use two 3 - 3-1/2” OD galvanized posts and secure with

concrete footings as shown, length to be determined by

local codes, frost line depth and soil conditions.

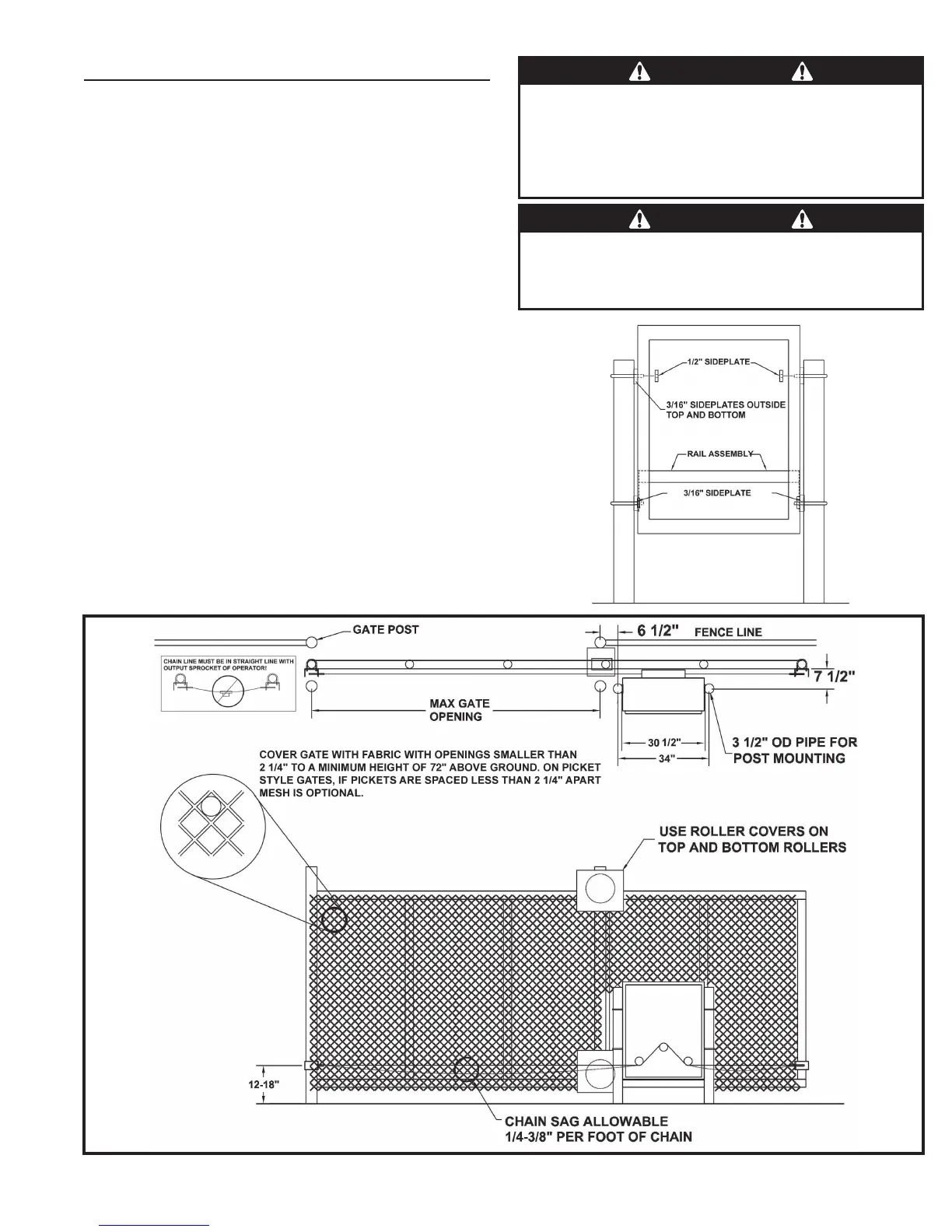

Attach the operator with the U-bolts, side plates and

hardware provided. Four 3/16” side plates go on the outside

top and bottom, two 1/2” side plates go on the inside top,

and two 3/16” side plates go on the inside bottom (see the

illustration at right).

To assemble the drive chain and gate brackets, refer to

Page 4. Make sure that the chain sag does not exceed

recommended sizes and that the chain does not come into

contact with the moving parts of the gate or ground.

Figure 2. Post Mounting Specifi cations

WARNING

The operator is intended for installation only on gates used for

vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to

promote pedestrian usage. Locate the gate such that persons

will not come into contact with the vehicular gate during the

entire path of travel of the vehicular gate.

WARNING

The gate must be installed in a location so that enough

clearance is supplied between the gate and adjacent

structures when opening and closing to reduce the risk of

entrapment.

Figure 1. Side

Plate Installation

Loading...

Loading...