19

GB

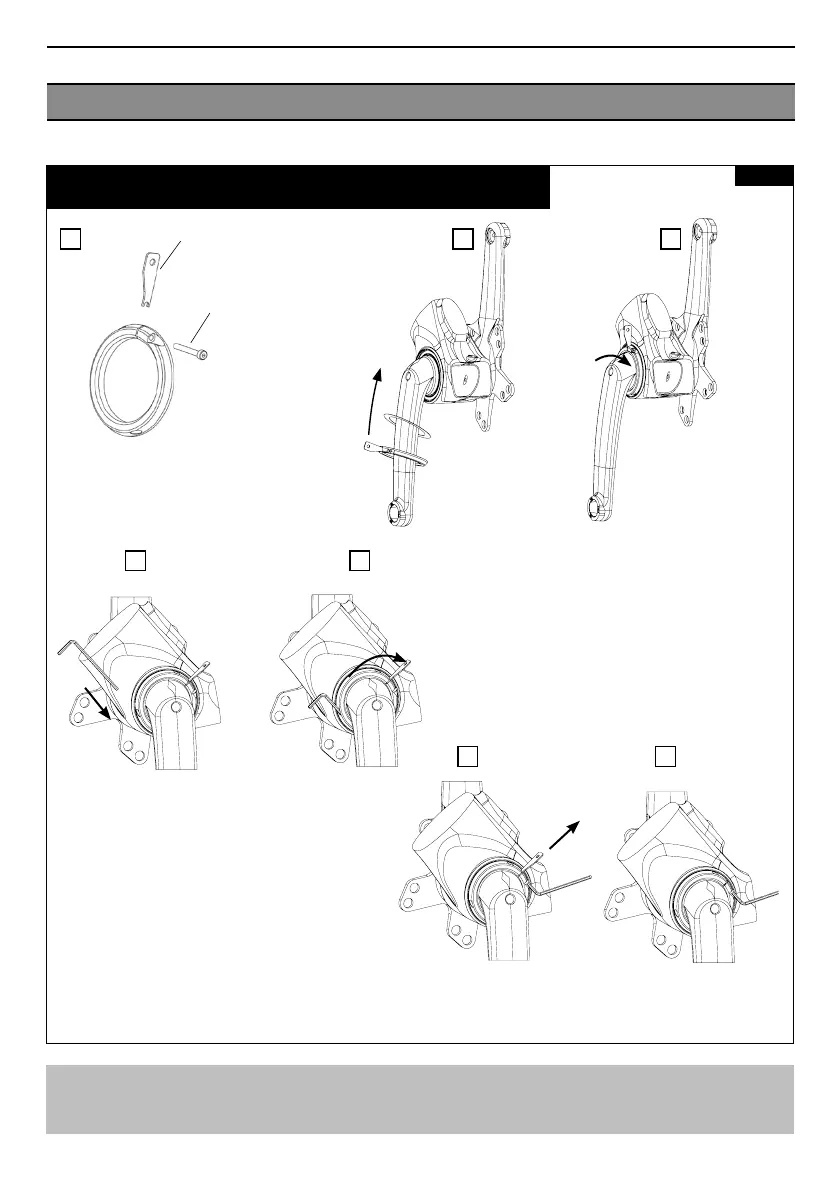

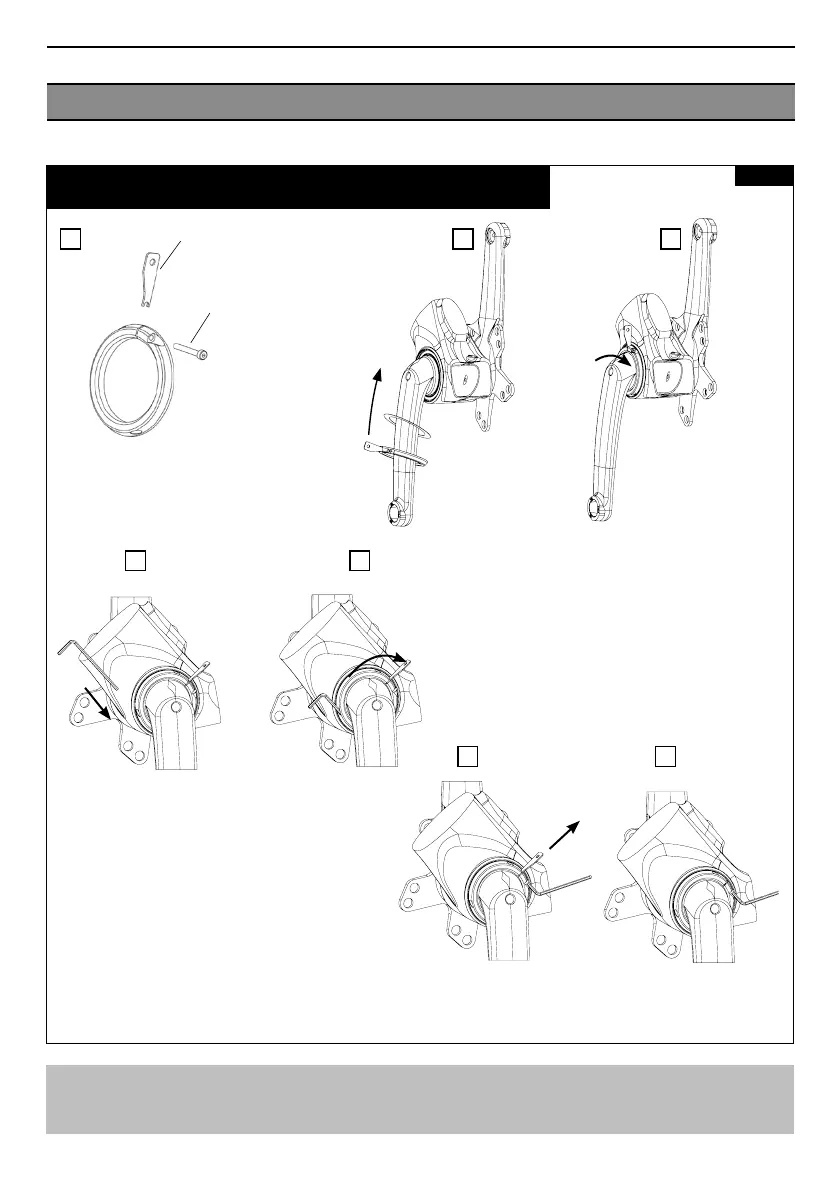

REMOVING AND FITTING THE CRANK ASSEMBLY 2/2

Fig 7

Removing the crank assembly from the frame:

To remove the crank assembly from the frame, follow figures 6 and 7 in reverse order.

A B C

D E

F G

After removing all gaps in the shell when tightening the nut, unscrew

the M3 screw, remove the fitting tool then re-screw the M3 screw to the

recommended torque of 2 Nm. to secure the nut threads.

Prepare the tightening nut by turning the fitting

tool in the 1mm slot using the M3x20mm screw

Torque: 2 Nm

Manually screw the

tightening nut onto the

first threads of the crank

assembly.

DO NOT FORCE as this

may cause irreparable

damage.

Flat gasket

Nut assembly

+ tool

+ M3x20 screw

M3X20 Screw Torque: 2 Nm

Insert the 2.5 Allen key into the hole opposite

the M3 screw to provide an additional means

of rotating the nut.

Nut fitting tool

Loading...

Loading...