14

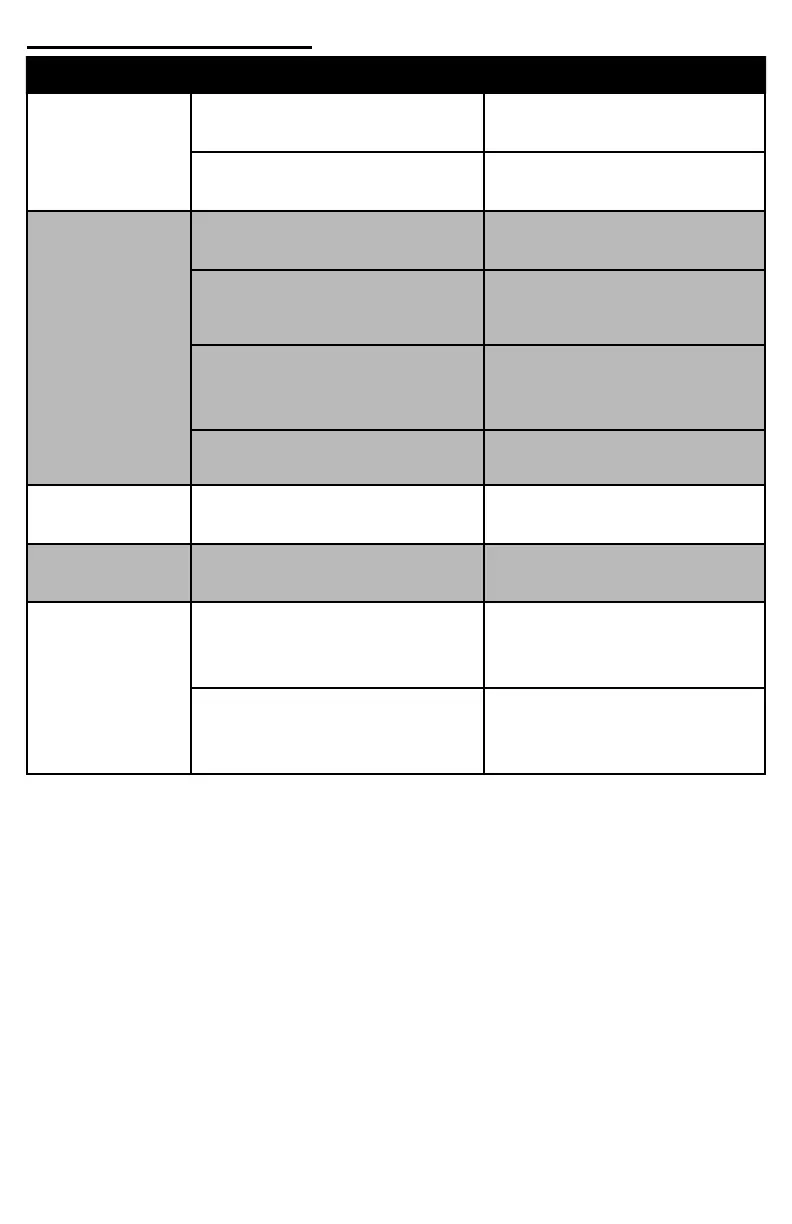

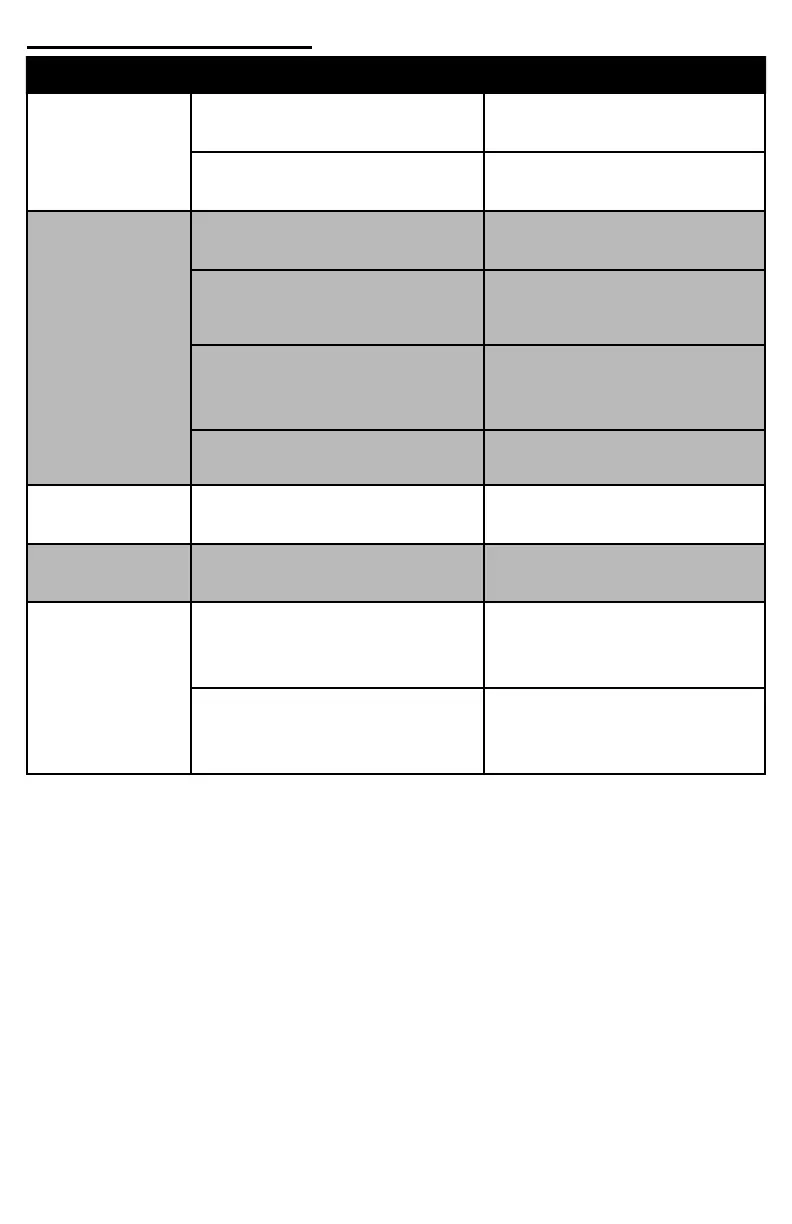

PROBLEM CAUSE SOLUTION

•

Tool skips off

to one side or

bounces

around

•

Stock is larger than tool will

accept

• Taper down the end of the

stock with a draw knife

•

Not enough pressure is being

applied

• Lean into drill with body

•

Not cutting

stock

• Stock is larger than tool will

accept

•

Taper down the end of the

log with a draw knife

• Blades are slid too close

•

Position blades so they are

back no closer than 1/8"

•

Blades are dull

• Not applying enough

pressure

• Sharpen blades

•

Purchase new blades

•

Lean into drill with body

•

Takes too much

of a "bite"

•

Aggressive cutting from dual

blades

•

Use the TB2500 Blade

Shims

• Crooked stake

•

Holding drill/tool crooked

while cutting

•Position drill/tool parallel

with the stock before cutting

•

•

•

•

•

Spiral grooves

on stake

Lateral wobbling of the drill

Hold the drill as steady as

you can while cutting

Removing the cutter while

drill is still spinning

DO NOT remove the cutter

until the drill has come to a

complete stop

TROUBLESHOOTING

Loading...

Loading...