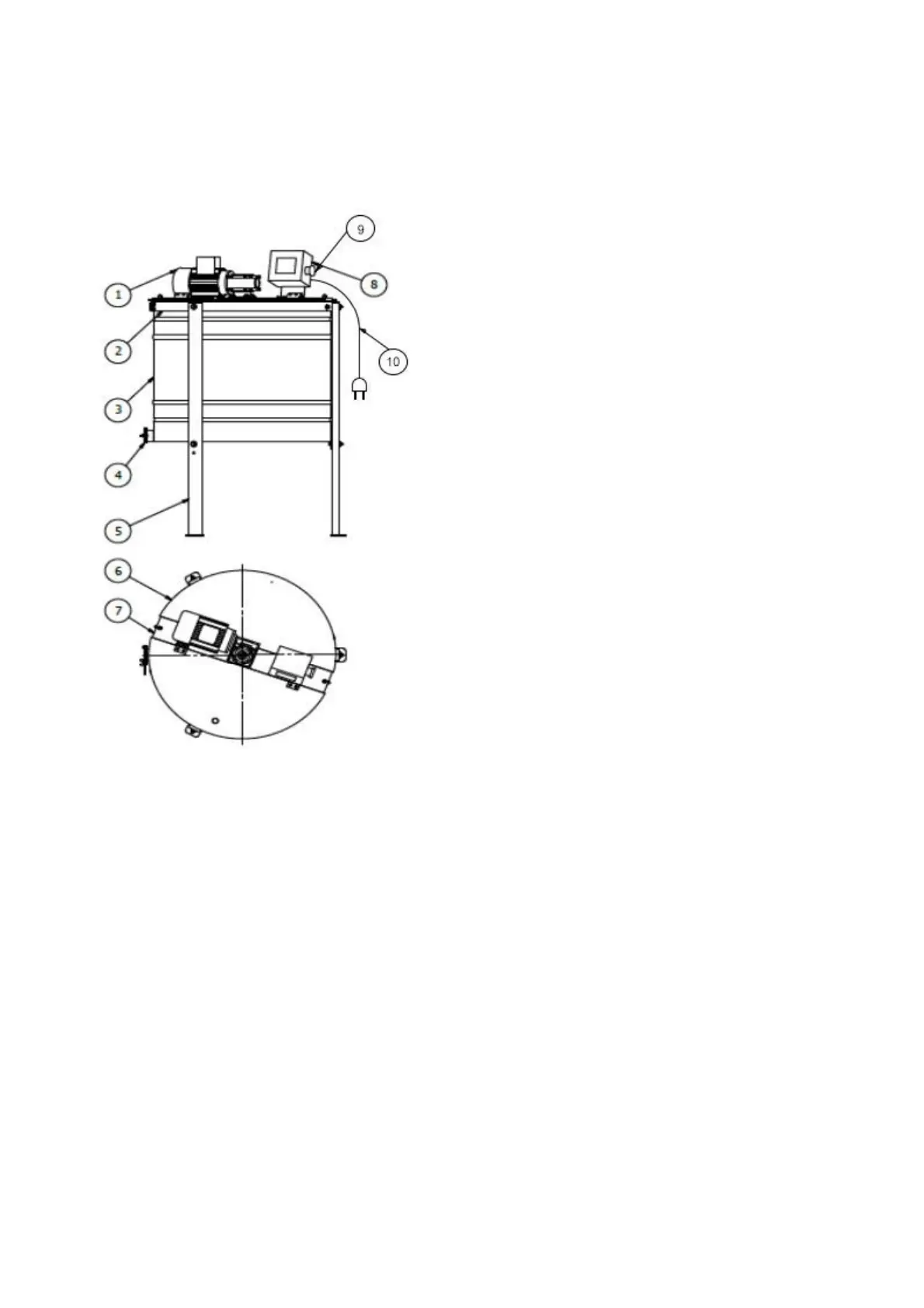

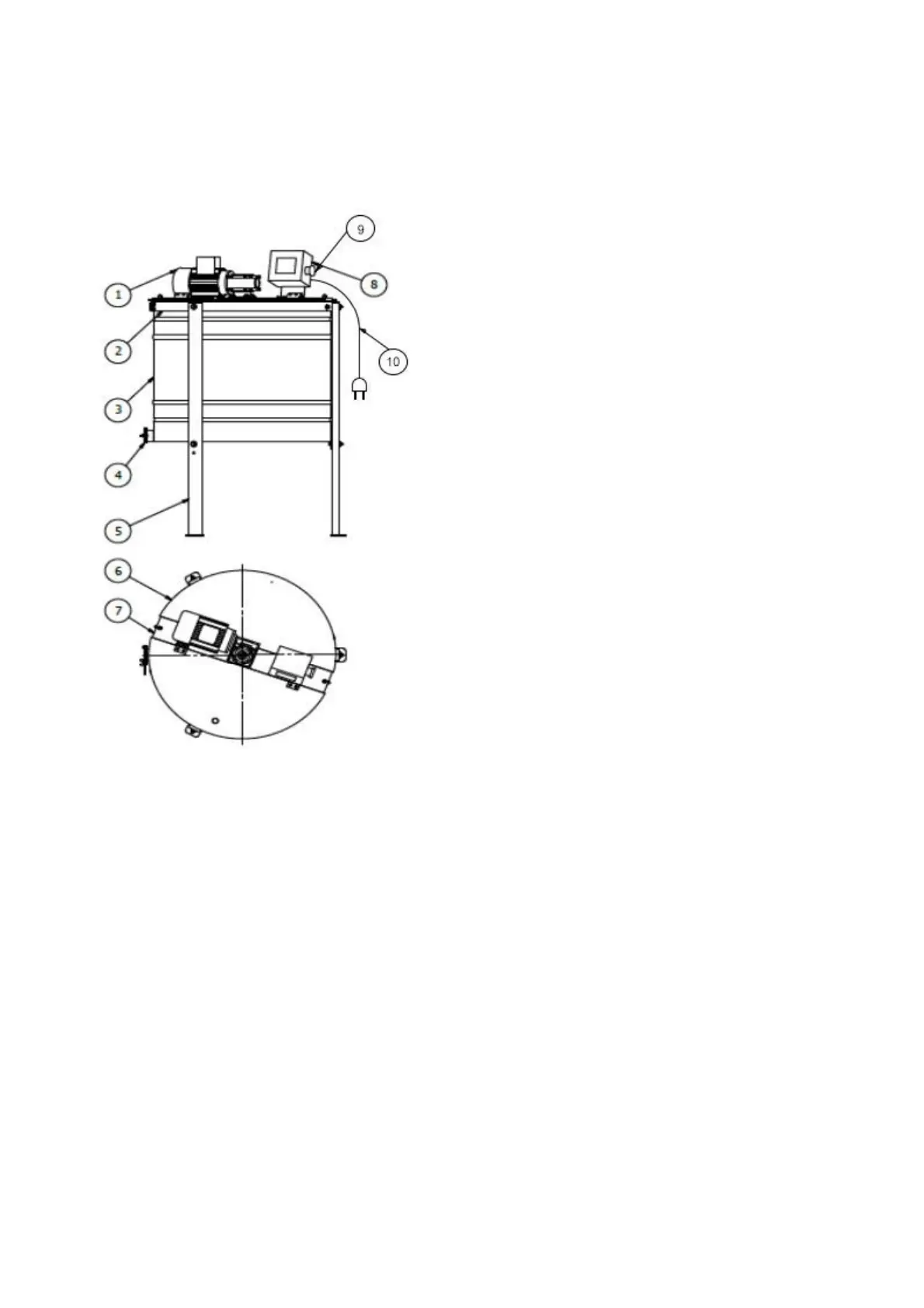

4. Honey extractors with upper drives

4.1. Diagram for honey extractor with upper

drive

1. Gear motor with an engine

2. Rim

3. Extractor drum

4. Drain valve

5. Extractor legs

6. Extractor lid

7. Extractor beam

8. Extractor controller

9. Emergency switch

10. Power supply cable

4.2. Characteristics for the honey extractors with

upper drives

4.2.1. Radial honey extractors with upper drives

Radial honey extractors are characterised by a possibility to

place a high number of frames inside the extractor basket.

Placing the frames in a radial arrangement makes the

spinning occur in one direction only. The drive is applied in

the honey extractors with diameters from 720mm to 900mm

Engine in radial honey extractors

• 720 – 0,37kW/400V/50Hz

• 800 – 0,37kW/400V/50Hz

• 900 – 0,55kW/400V/50Hz

4.2.2. Cassette honey extractors with upper

drives

• Cassette honey extractor are intended for bigger

apiaries. The spinning cycle occurs in two

directions and owing to the guides installed, there

is no need to rearrange the cassettes manually and

the possibility of their jamming is excluded

Engines in cassette honey extractors

• 720 – 0,37 kW/400V/50Hz – 4-cassette honey

extractors.

• 800 – 0,37 kW/400V/50Hz-extractors with 4

cassettes, 6 cassettes.

5. Controlling in cassette or radial honey

extractors with upper or bottom drives

5.1. Semi-automatic controlling

• HHoney extractor with this controller may work in a

manual mode ( 2 programmes) and automatic

mode. In manual mode speed and direction may be

set in manual mode with a potentiometer

• pAutomatic mode is factory-set

5.2. Automatic controlling

• Automatic mode has 8 programmes. The first two of

them are intended to work in a manual mode, the

third one – automatic, is set by default

• pProgrammes from 4 to 8 allow to enter own

settings. Each programme consists of 7 steps.

During each step three parameters may be set up:

time of step starting, set speed and spinning

direction. The last step defines the time for the

extractor basket stopping. .

5.3. Advanced automatic controlling

• has 8 fully programmable automatic cycles

• 2 automatic manual cycles

• big (4,3”),coloured TFT graphic display with energy

saving LED backlight and the resolution of

480x272 pixels

• handling through 8 ergonomically arranged

controlling buttons

• simple and intuitive user’s interface using high-

contrast graphics to provide high visibility

• graphic editor for spinning cycles – equipped with

the function of parameter auto-correction

• 2 independent extractor operating time meters

Loading...

Loading...