5

TECHNICAL DESCRIPTION

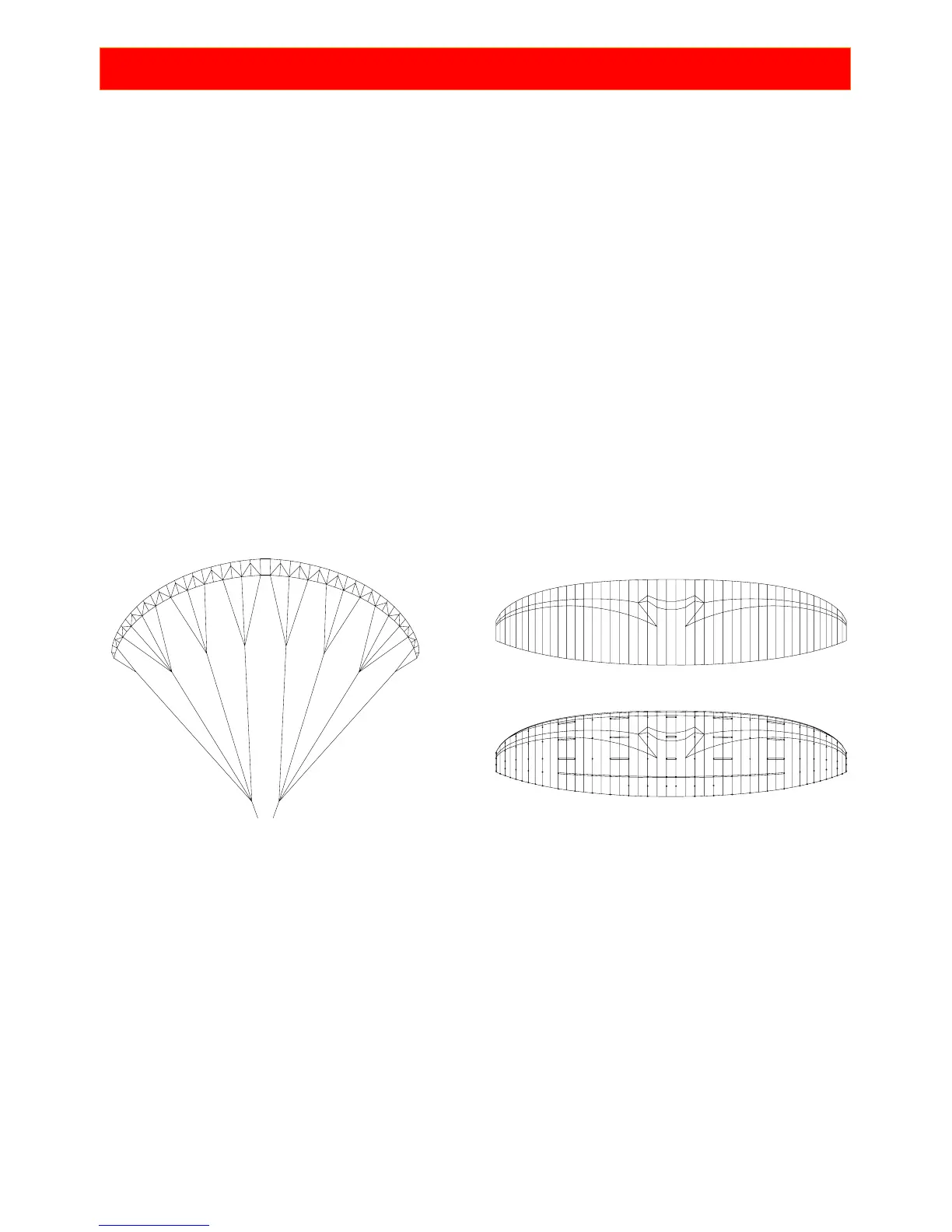

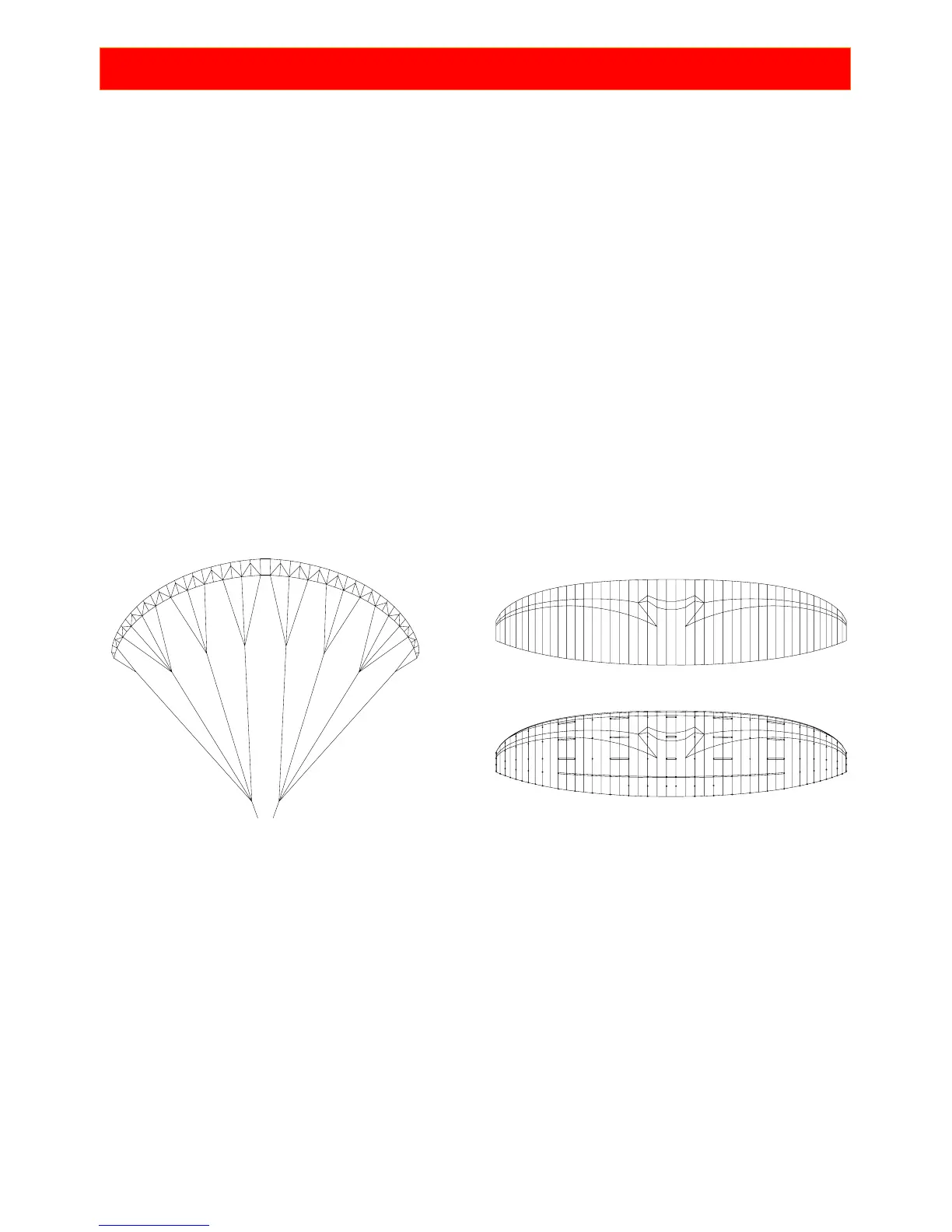

Construction of the canopy:

The canopy of the MUSE 3 consists of 45 cells over the wingspan. The wingtips are

slightly pulled down and this produces a kind of stabilizer. The Muse 3 is a second rib

diagonal-construction paraglider. Every second main rib is attached to the 4 or 5

suspension lines. Between these main suspension ribs, intermediate ribs are

suspended by diagonal segments. These segments do not lead to top surface of canopy

but are attached at 80% of rib's height. This construction ensures a smooth top surface

and precise airfoil reproduction. The internal reinforcements maintain the precise form of

the canopy and provide stability. The cell openings on the under-surface of the profile's

nose provide airflow into the glider. Stretch resistant flares, integrated with diagonal ribs

at the suspension points, ensure an even distribution of load throughout the canopy. A

stretch resistant Mylar strip on the top and bottom panels alongside the openings and

running the length of the trailing edge defines the wingspan, together with an optimized

sail tension; this guarantees a high form stability. Large cross ports allow effective

airflow inside the canopy, providing good re-inflation without reducing the profile

accuracy..

The Muse 3 is mainly made of the proven Nylon fabrics Porcher Marine Skytex Rip-stop

9092 E85A, 9017 E38A and 9017 E29A. Like any synthetic material, this can deteriorate

through excessive exposure to UV.

Rigging system:

The lines of the Muse 3 are made of proven strong and stretch resistant Polyester HMA

Aramid/Kevlar (yellow core) lines and PES/Dynema (white core) lines. The entire rigging

system comprises individual suspension lines looped and stitched at each end. The

Arami/Polyester main lines have strengths from 160 up to 240 kg. The Aramid cascade

lines have strengths from 60kg up to 80 kg. The Dynema brake lines have strengths

from 100kg up to 240 kg

Loading...

Loading...